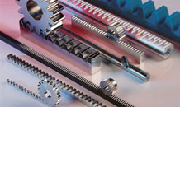

Halifax Rack and Screw Cutting Co Ltd

Precision gear racks have longer in service lives, smoother performance characteristics and more accurate pitch control than other machining techniques.

HRS can machine in straight gears, spur and helical gears with tooth forms up to 45 degrees, with a 450 mm / 17.75 inch face width and height and up to 12metres / 40 foot long.

HRS utilises specialist dedicated CNC rack cutting machines to ensure highest accuracy up to AGMA class 10 spacing tolerances.