4 Common CNC Turning Problems and Their Solutions

2 June 2021Computer Numerical Control (CNC) turning is a practical and efficient way of manufacturing custom components. However, while CNC lathes are capable of producing consistent results in a speedy and cost-effective manner, there are things that can go wrong with the process. Let's look at four of the most commonly experienced CNC turning problems and examine what can be done to resolve them:

1) Your components are poorly finished

There are a number of factors that can mean that your components aren't being finished to the standard you'd expected, so you'll need to do some detective work. Firstly, you may be using a cutting tool that's too blunt or that's unsuitable for the job. If that's the case, it will need to be replaced. It's also possible that you haven't used the most appropriate settings for the job so check all of them (including coolant) and make any necessary adjustments before trying again. Finally, there may be dirt or debris in the machine. This situation can be avoided by putting a regular maintenance schedule in place.

2) The machine tool is too hot

If the tool overheats, it can have a negative impact on your results and even cause long-term damage to your CNC lathe. Sometimes dirt can be the culprit, so regularly cleaning your machine is essential. It's also important to lubricate the spindle properly to prevent friction, as this could generate unnecessary heat. CNC lathes can also be sensitive to environmental factors, so try to keep the temperature and humidity in your factory constant 24-hours a day.

3) The programme isn't running as expected

The most likely cause of this issue is human error. Contemporary CNC lathe machines are extremely reliable, but they need to be operated by skilled workers. If incorrect data has been entered into the machine or it's been put in the wrong mode, errors will occur. To avoid this type of issue arising, ensure that anyone operating the machine has been fully trained and that they have the relevant instruction manuals to hand.

4) The machine is vibrating or chattering

If your CNC lathe is vibrating more than usual or making a "chattering" sound, something is amiss. If you don't resolve the situation immediately, your components may not be manufactured to the necessary standards and you could cause costly damage to your machine. You may need to adjust the spindle speed or check the wear and tear on your spindles and drives in order to resolve the problem.

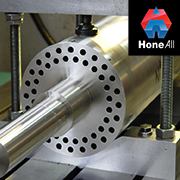

Outsourcing Your CNC Turning To Hone All

The easiest way to minimise the number of problems that you experience, however, is to outsource your CNC turning tasks to an excellent partner within the sub-contract precision engineering sector. At Hone-All Precision, we use state-of-the-art machinery and our staff are trained to the highest standards, so you'll get outstanding results on any precision engineering project. Complete our online form to request a free quote.