7 ELEMENTS OF THE HONE ALL PRECISION ROLLER MANUFACTURING PROCESS YOU NEED TO KNOW

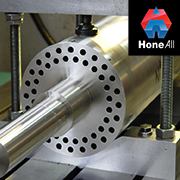

26 March 2019At Hone-All Precision, we specialise in precision rollers for a wide range of industrial applications. Our products are manufactured precisely to your design and machined for optimum efficiency and cost effectiveness. Whether you need 20 identical parts or a single, custom roller for a one-off project, our roller manufacturing process is geared up to provide the highest quality components available on the market.

We have a wide range of CNC equipment at our facility which we use to fulfil our customer orders. Each project is different and we apply the most appropriate techniques in every case, but when you work with Hone All the following seven elements each play a part in the roller manufacturing process.

1) Send us A Quote Request

We price each of our projects individually, so the first thing to do is request a quote. You can do this online by clicking here. Tell us a little bit about your requirements, including any project deadlines, and attach your drawings. Working from complete design drawings is crucial to successful manufacturing, so please provide the most accurate and up-to-date versions. We’ll take a look through and call you back if we have any questions. Or you can drop by and see us in person with your drawings.

2) Contract Review & Feasibility

Once we’ve received your drawings we will assess them for manufacturing feasibility. This is an important part of the process, as it allows us to identify any potential challenges and suggest alternations to your specs if necessary. We aim to ensure your drawings reflect exactly what you need and also ensure all your parameters are achievable. The result is accurate drawings that you can use time and again on your projects – whether with us or with another manufacturer. A thorough analysis at this stage saves a lot of time further down the line.

3) Quotation Sent

We will send you a written quote for your approval. We can review and adjust this based on budgetary constraints or changed requirements.

4) Manufacturing

Our CNC machines allow us to produce precision rollers to our customer’s exact requirements. We have the flexibility to create custom parts for applications in any industry, including motorsport, pharmaceutical, printing, medical manufacturing and the automotive sector. Tolerances can be carefully defined through additional finishing processes.

5) Dynamic Balancing (if required)

To optimise rotational speed and reduce unwanted heat wastage and vibrations.

6) Inspection

We undertake a full dimensional inspection to ensure your parts exactly meet specifications. We carry this out in house with our own CMM machines and trained operatives.

7) Despatch & Delivery

On completion, we can deliver your parts by courier to any address in the UK.

The Ultimate Free Guide to Industrial Rollers

More information about industrial rollers can be found in our new Industrial Rollers Guide. This free resource can be downloaded directly from our website and contains useful information about how to source the best industrial rollers.