Applications Of Thin-Wall Tubular Components In Modern Food Processing

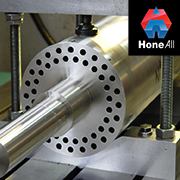

1 March 2024Thin-wall tubular components play a vital role in modern food processing equipment and operations. With highly skilled expertise, and advanced manufacturing methods, enabling precise dimensions and finishes, these lightweight yet durable components deliver crucial advantages that promote improved hygiene, efficiency, and food safety across the industry.

Contact The Team at Hone-All Today

In this article, we’ll consider what thin-wall tubular components are and why they are suited to the demands of the modern food processing industry.

What Are Thin-wall Tubular Components?

Thin-wall tubular components are lightweight tubing and piping with walls as thin as 1mm, sometimes less. They are precisely engineered with tight dimensional tolerances using advanced manufacturing techniques; despite their thin profile, they maintain exceptional strength and structural integrity without the weight of traditionally fabricated parts. Made from stainless steel or other durable alloys, these corrosion resistant components support the design of hygienic, cleanable systems, while precision tolerances result in exceptionally smooth, crevice-free surfaces that are polished to a uniform finish.

So, what benefits do thin-wall tubular components offer for the food processing industry?

Hygiene And Cleanability

The polished smooth walls of thin-wall stainless steel tubular components minimise areas where food residue and contaminants can adhere. Combined with a high precision fit, this facilitates thorough cleaning and sanitisation to maintain stringent hygiene standards. Ease of cleaning supports compliance with hygiene regulations and guidelines in food production facilities, ensuring products leave the facility in prime condition and protecting consumers from potential harm.

Corrosion Resistance

Constructed from high grade stainless steel that has been optimised specially for the food industry, thin-wall tubular components are highly resistant to corrosion, even when exposed to repeated cleaning cycles and wet ingredients. Their durable construction ensures strength, chemical compatibility with cleaning agents, and longevity even in demanding processing environments.

Dimensional Accuracy

Machined to exacting tolerances, thin-wall tubular components deliver reliable and consistent performance. Tight seals prevent the ingress of contaminants while promoting optimal flow and hygiene, which facilitates compliance with strict safety and quality control protocols across pumping, mixing, heat exchange, material conveyance, and other critical applications.

High-precision thin-wall tubular parts deliver exceptional safety, quality, and efficiency in food production. As manufacturers aim to meet consumer demand for cleaner labels and greater transparency, high-performance components will increasingly provide smart and streamlined processing solutions.

Find Out More

At Hone-All, we provide end-to-end precision engineering for UK food and beverage producers who are seeking cost-effective solutions that won’t compromise product safety or quality.

To find out more, please call Hone-All today on 01525 370666 to chat to our experts about your business’s needs.