How To Save Money On Deep Hole Drilling, Boring & Honing

21 June 2021Tubular based components are used in tens of thousands of applications by manufacturers in a wide range of sectors. These components vary enormously in size, capacity and use, but the method by which each is made is broadly similar.

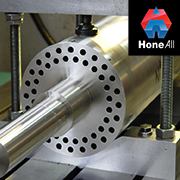

The precision engineering methods used to make industrial tubes and shafts include deep hole drilling, deep hole boring, gun drilling, CNC turning and CNC honing.

We have written a new Guide to Deep Hole Drilling, Boring & Honing Costs for two reasons:

- Firstly, to explain what these things are and why they’re important, and

- Secondly, to explain why you may get two or more very different quotes from different suppliers for the same job!

When approaching a supplier, how do you make sure you end up with the right specs AND get the best value for money?

Quoting for deep hole drilling, boring and honing is not always straightforward but it isn’t a dark art either. Some companies may provide standard quotations raised on a standard spreadsheet, but this isn’t always an accurate reflection of costs. The project could end up overshooting the agreed timescale, accruing additional costs or not measuring up to your technical specifications. To avoid this, we always quote on a bespoke basis and only after fully understanding the technical requirements of your product, application and the timeframe you are working to.

In our guide we explain our reasons for doing so, by revealing the factors that affect your quote and the overall quality of your product.

Sections cover topics such as:

- The manufacturing process

- Engineering quality standards and why they matter

- Why complete technical drawings and a thorough understanding of the application are important

We also try and clear up some common misunderstandings/misconceptions and provide solutions to some of the frustrating issues faced by manufacturers when dealing with suppliers. For example:

- What is ‘wander’ and how does it affect your end product?

- How do you achieve the right balance of cost versus quality?

- What is the best way to work with your supplier to guarantee consistent results and on-time delivery?

How To Claim Your Copy Of Our E-Book

You can access a complimentary copy of our guide by filling in the simple form on this website. Click here to visit the page. The Guide is a useful resource for any business considering contracting out deep hole drilling, honing or boring – and comes with no obligation to use our services. The same principles of accuracy, engineering standards and customer communication apply regardless of the supplier you choose to work with.

About Hone All

At Hone All Precision we are a family run engineering firm with extensive experience serving clients in the petrochemical, medical, packaging, printing, aerospace, motorsport, hydraulics and automotive manufacturing sectors. Our full range of services are carried out in-house at our Leighton Buzzard (UK) workshop by a team of experienced, qualified CNC engineers. If you’d like to chat with one of our engineers about a project you’re working on, or request a bespoke quote, please call us on 0845 5555 111 or 01525 370666.