QUICK QUOTING VS QUOTING FOR OVERALL QUALITY ON SPECIALIST SERVICES

26 March 2019In this article we would like to talk about quotes; specifically, why specialist CNC engineering companies charge what they do. There is a cost versus quality debate in every industry we can think of. The argument possibly goes that the lower the quote, the more corners must need to be cut at the suppliers’ side in order to achieve the price while still returning a reasonable profit. This usually leaves a fairly wide margin for flexibility, but it also means that a race to the bottom towards ever lower prices is rarely beneficial for either customers or suppliers in the long run.

In the field of precision machining, the price versus quality debate can, fortunately, be quite accurately quantified in terms of what is included in the quote. Unfortunately, being highly specialist services, Deep Hole Boring and Drilling are not too widely understood, even within the manufacturing sector. Of course, no company in the world is going to suggest that they don’t provide a quality service, no matter how low the quote. It is therefore easy to misunderstand the real term value delivered by a quote, relative to the price charged.

A Question Of Tolerance

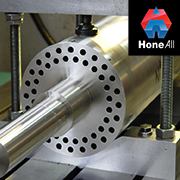

Tolerance is a major variable when carrying out Deep Hole Boring and Drilling. A skilled machinist can use a Gundrilling machine to drill to a tolerance of +/- 0.05mm for a standard 10 mm diameter bore. As the diameter increases, so does the safe margin of tolerance. A bore above 15 mm, for instance, should aim for a tolerance of no more than +/- 0.1mm. For deep hole drilling in excess of 20 mm diameter or more, the standard industry tolerance for a drilled or bored hole only is +/- 0.25mm.

If the tolerance required is tighter than these margins, honing will be required. This is an additional process which adds to the cost of the project. However, many low-priced quotes include drilling or boring only and not honing.

This allows the supplier to reduce the cost of the quote upfront and maybe secure additional business. However, by excluding honing, a quality result is not always guaranteed. If the final bore falls short or wide of industry-standard tolerances, the customer may need to undertake further honing at extra expense. This is frustrating and can cause additional costs and delays.

For projects on a ‘Deep Hole Boring or Drilling only’ quotation, this will blow the agreed price out of the water, as the quote suddenly no longer reflects the full cost of the project. The customer will find themselves faced with escalating costs and missed delivery deadlines, with no control over the final outcome.

This is not a good situation for either the machinist or the customer; and is why we always choose to be cautious, carefully review the complete requirements of the component and place quality controls and the possible requirement for honing at the heart of every project we undertake. We also request that our customers carefully check the tolerances quoted on alternative quotes as they can often be omitted or quoted at a different tolerance to that stated on the drawing but is indeed, the standard offered tolerance from the company quoting.

Standardised & Quality-Based Quotes

As you can see, simply quoting for Deep Hole Boring or Drilling without honing does not consider the full scope of work involved in a project. A company that quotes only for boring will undoubtedly be able to offer a lower price upfront. However, this places the customer in a risky position, as honing is not included.

We don’t believe in this method as we feel it does not benefit anyone in the long term and simply jeopardises quality and the long-term success and reputation of both companies, so instead of giving you a standard ‘nuts and bolts’ quote covering specific actions only, we quote according to the amount of work required to not only meet, but also exceed, the desired finished quality.

‘Quoting for quality’ is therefore a more accurate assessment of the cost and lead time of the project. This is why we don’t generate quotes using standardised spreadsheets and why we won’t give a quote without fully reviewing your technical drawings and conducting a full contract review at the quotation stage mapping out the implications of the job, not just at our first or second stage of machining but taking into consideration the final requirements of the project after further machining and treatments.

It is also why our quotes are not always the lowest on the market: they take into account the possible preparation work required on the material (such as facing or straightening when required) in addition to any honing work that may be required to get you the results you need. On the other hand, our quotes do give you enhanced peace of mind, as you can be assured of the accuracy of the final result and that you will not be saddled with additional expenses or potential delays you, or your end customer, hadn’t accounted for.

Our thorough approach allows us to identify potential issues at the quotation stage, equipping us to provide a more cost-effective, high-quality solution than a standard ‘price per inch’ quote could ever do.

To find out more about our approach to quoting Deep Hole Boring & Deep Hole Drilling for industrial rollers, take a look at our Industrial Rollers Guide. This free e-book contains valuable information about the machining process; including how to establish accurate technical drawings, avoiding drilling errors and achieving the best value for money. The parameters mentioned and information included within the guide can be applied to the machining of any precision, tubular component so even if you’re not involved in the Roller Manufacturing industry, it may still be worth downloading and a few minutes of your time.