Hone-All Precision Ltd

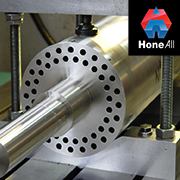

Our deep hole drilling service prides itself on being able to produce accurate, concentric bores time after time. We have the mechanical ability to perform deep hole drilling on all materials and can machine shape bars, blocks, castings and finished components.

Often referred to as gundrilling, at Hone-All, we use of deep hole drilling services to create precision, circular bores to gain close tolerances.

-

The Importance Of In-house Professional Development In Manufacturing!

1 December 2022The skills shortage affecting the UK’s manufacturing sector is well-documented, the result of a combination of factors, including the changing face of the British workforce, the political upheaval of recent years, and the long-term impact of the Covid-19 pandemic. Although many fields of industry are affected, manufacturing is suffering the most, with an estimated 85 per cent of businesses in the sector experience problems because of a shortage of skilled workers.

For manufacturers, the consequences of a major skills shortage could be severe if decisive action to counter the problem is not taken immediately. Reduced productivity and higher operational costs can impact output and turnover which, combined with an unstable economic landscape, could spell disaster for some businesses.

What role does in-house professional development have to play and what difference could it make for your business?

Why Upskilling Your Team Matters

In the face of a persistent skills shortage, your existing team really is your best resource! If you upskill your employees to ensure they are trained in manufacturing best practices, you can overcome many of the obstacles facing other engineering businesses. It is also important to promote the job opportunities available in your company to attract young people, encouraging them to cultivate science, technology, engineering, and mathematics (STEM) skills, which will be a fundamental element of building the skilled workforce of the future.

Upskilling your team means you can draw upon the experienced staff members that you already have, to reap the benefits of an up to date, skilled workforce:

- Futureproof Your Business by ensuring your employees have a variety of skills and knowledge to shape your organisation in preparation for future changes.

- Motivate Your Team by investing in their professional development to learn new skills, increasing their self-worth and loyalty to your company.

- Save Money by increasing the scope of your existing team instead of recruiting new staff.

- Increase Productivity by giving your team the skills they need to undertake new projects efficiently.

- Cement Your Reputation as a business that invests in its staff’s professional development, so that your company becomes known for its commitment to its people, thereby attracting new talent when vacancies arise.

Why Financial Support Should Target UpskillingAlthough the Government awards grants to enable manufacturers to recruit new staff, many businesses in the sector would prefer to use the money to upskill their team.

It’s an issue Hone-All’s director, Andrea Wilson, recently raised during a key interview on GB News, in which she highlighted the urgent need for manufacturing small and middle-sized enterprises (SMEs) to be supported to train the unskilled, as well as upskill their teams, as a way to narrow the skills gap.

She believes the Government could save millions on capital equipment placed into colleges, who struggle to remain current with technology and find it impossible to recruit skilled lecturers to teach.

By re-allocating some of this funding into a Training and Development Tax credit system (similar to the R&D system), we could reduce budgets, address the skills gap, and give thousands of unskilled people the chance to join a vibrant, exciting, and thriving sector.

So, if you want to futureproof your manufacturing business, increase its competitiveness and resilience, and open new production avenues, invest in upskilling, as addressing the ever-increasing skills gap will be vital for your business, the manufacturing industry, and the UK’s economy. For more information about our services, please contact us today!

- Futureproof Your Business by ensuring your employees have a variety of skills and knowledge to shape your organisation in preparation for future changes.

-

How Honing Reduces Hydraulic System Failure

1 December 2022A hydraulic system failure is always inconvenient and costly but, in some industries, it can put users at serious risk of injury or death. Aircrafts, for example, rely on hydraulics to move critical mechanisms, including the landing gear, brakes, and wing flaps, so any system failure could result in catastrophic consequences.

Honing: The Key To Hydraulic System Performance

CNC honing is a highly precise machining technique that is used to form exceptionally smooth, cylindrical surfaces. An abrasive, or diamond, stone is used to apply pressure to the surface of the component to size it, and create particular surface finishes, according to exceptionally detailed specifications.

When assembling hydraulics systems, including cylinders and pipelines, CNC honing plays a critical role. The interior of hydraulic components depends on incredibly precise volumetric measurements and must be honed accordingly to ensure it is smooth and dirt-free if optimum performance is to be achieved.

Honing reduces hydraulic system failure in several ways:

1) Superior Part Lifespan

In hydraulic systems, premature failure or aging of parts must be avoided. Honing helps minimise the risk of metal wear, component disintegration, or splits in pipework or tubing. Metalwork that is finely honed eradicates the surface inconsistencies that cause metal to wear unevenly, thereby avoiding the problems associated with imbalanced pressurised fluids.

2) More Durable Pistons

Honing the surface of pistons enables them to wear more slowly and deliver more durable performance over a longer period. Because pistons move forward and backwards quickly to move loads or pump liquid, they are subjected to excessive strain, so it is essential to minimise wear, friction, and fluid resistance to keep the hydraulics system operational. By creating a surface finish which aids oil retention, honing improves the performance of the pistons and achieves more precise tolerances, while also helping to keep piston enclosures and chamber connectors sealed tightly.

3) Improved Performance

By honing the interior surface of a hydraulic cylinder, smoother movements can also be achieved due to less friction, so fluid is moved more consistently through the system with less wear on key components, such as pistons. Efficient transmission of hydraulic fluid is critical if the system is to operate safely and effectively, so honing is key to eliminating the inconsistencies that could prevent the smooth movement of fluid.

‘Crosshatch honing,’ in which both axes are crossed at the same time, is also an invaluable honing method as it shapes a cylinder surface to be flatter for piston contact and prevents piston wear due to increased oil retention.

Contact Hone-All To Find Out More

At Hone-All, we offer a high-quality and reliable CNC honing service that guarantees the finished component is safe and durable, so you can be assured that you won’t be faced with substandard parts that cause an irretrievable hydraulic system failure.

To request a free, no-obligation quotation or to find out more about our honing services, please call us on 01525 370666, visit www.hone-all.co.uk or send us a message and our team will be in touch.

-

Manufacturers: How To Stay Positive Despite The (Potential) Looming Recession

1 November 2022For months, news coverage has been dominated by talk about the possibility that the UK economy will soon be hit by a major recession. It’s something we’ve heard plenty of times before, with predicted recessions vastly outnumbering genuine downturns. This being said, it’s sensible for manufacturers to be prepared for all eventualities, including how to operate and to thrive during a possible economic downturn.

A Self-Fulfilling Prophecy?

In truth, recessions often happen when businesses buy into the negative mindset that such a situation is ‘unavoidable.’ While recessions can, of course, be driven by other factors outside the control of manufacturing companies, there are many instances when predicted downturns have failed to materialise because individual businesses have refused to be influenced by catastrophic forecasts – such as in the immediate aftermath of the Covid lockdowns. The newsfeeds were full of gloomy predictions, but businesses were having none of it. By refusing to talk themselves down or stop making plans for growth, businesses avoid the knee-jerk reactions that are more likely to make recession a reality.

In fact, with negativity proliferating in the news, it’s always better to adopt a positive stance and focus on the good things that are happening in the industry. Within manufacturing, there are many ambitious programmes in place to raise the uptake of engineering at school, increase recruitment, and override the negative perceptions that many have of the sector. Currently, an important initiative is the fight for a Minister for Manufacturing, with many companies joining forces to highlight the benefits for the industry.

One of the most encouraging players in the manufacturing industry is Mark Weymouth, whose #FridayGOODnews posts regularly highlight the positive developments and initiatives taking place.

Futureproofing Your Manufacturing Business

If a recession does occur, it’s vital that manufacturing businesses are well-prepared, resilient, and able to ride out the storm. What steps can you take now to future proof your company?

Guarantee Service And Performance

Ensure you are delivering the best levels of service and performance for your customers. Ensure you are their preferred choice for the placement of orders and make sure you communicate regularly with them regarding your performance and any other opportunities that may exist within their business for you. Do not be tempted to panic and reduce prices in the face of any potential recession as most customers need security and longevity of supply, rather than a quick price reduction in the short term.

Monitor Your Cash flow

If a recession is looming, take action to reinforce your cash-flow management immediately:

- Plan your cash-flow for the next three to six months.

- Prepare measures to make efficiency savings as soon as a recession seems inevitable – without, if possible, making people redundant or scaling back important capital investments.

- Run simulations to help you to anticipate the effect of decreased revenue on your cash-flow.

- Review payment terms with customers and suppliers and implement early-settlement discounts or online billing to encourage prompt payments.

Manage Your Debts

Negotiating with lenders is most effective when you are in a position of strength. Increasing your credit will give you access to working capital when it is most needed. Waiting until the financial pressures are bearing down will make it less likely that you will receive a sympathetic hearing.

Generate Flexibility

Embedding flexibility into your business operations will enable you to scale down your costs rapidly, should the need arise. Converting fixed costs to variable costs gives you greater manoeuvrability should the financial climate worsen. There are many ways to do this, such as:

- Increasing overtime instead of recruiting new staff.

- Hiring contractors for seasonal or short-term work.

- Outsourcing highly complex work to specialist providers, such as Hone-All, rather than purchasing new, expensive equipment.

Reinforce Your Supply Chain

Strong relationships with suppliers and vendors will enable you to stay abreast of market developments and maintain a fluid supply of components or raw materials. Long-term contracts with your suppliers will help to protect your business during a slowdown.

Remember that a recession is not inevitable but, by taking sensible steps now, your business will benefit from cost savings and improved efficiencies even if the worst-case scenario never occurs.

For more information about our products or services, please get in touch today, or visit our website.

-

How Manufacturers Can Reduce The Impact Of Higher Energy Costs

1 November 2022In manufacturing, efficiency is key to unlocking success and profitability. Businesses can strive to improve their efficiency in many areas of their operations but, where energy efficiency is concerned, external influences play a significant role in determining how much of your annual budget will be spent on electricity and gas.

Rising energy prices, which have continued unabated this year, have occurred because of increasing global demand, weaknesses in supply, and geopolitical problems, such as the war in Eastern Europe. But according to Government research, manufacturers in the UK could reduce their energy use, on average, by one-fifth by implementing some simple measures.

Adapt Your Business Practices

The most effective energy saving practices involve everyone within the business, so it’s important that your entire team is on-board and actively engaged in cutting costs. Sometimes, the most minor of changes to business practices can generate significant savings, so instigate these measures to start reducing your energy bills immediately:

- Reduce the temperature of the workplace by one degree.

- Keep windows and doors shut to retain heat.

- Reduce demand for artificial lighting by installing sensors in less populated areas of the premises.

- Switch off machinery and equipment when not in use.

- Turn off motors when not required or between job changes.

- Ensure equipment is maintained regularly to ensure it runs at optimum performance level.

Negotiate Energy Tariffs

Whilst the Government have introduced a temporary cap, we don’t know if it will continue after March. An energy fixed tariff offers considerable certainty about how much you will pay for your electricity and gas consumption over the term of the deal. When global prices are highly volatile, it makes sense to fix your energy costs so you can budget more effectively from month to month and insulate your business against rising costs in the future. Discuss your options with your current energy supplier but don’t be afraid to shop around to see whether more preferential rates are available elsewhere.

Factor Rising Costs Into Your Product Prices

When you are operating to tight product margins, even slight increases to your energy bills will impact on how much profit you can derive from each sale. While nobody wants to increase the retail price of their products and dissuade customers from purchasing, it’s vital that your manufacturing business remains profitable and viable. Offsetting the increase in energy prices against other costs, for example by negotiating more competitive raw materials, can also limit how much you need to raise product prices. Currently, businesses and consumers tend to be more understanding, as for once, we are all in the same situation.

Inject Capital From Other Areas Of The Business

If your organisation has available capital that isn’t tied up in other areas of the business, you can re balance your budget by diverting money into your energy fund. For example, this might include outsourcing specialist machining to an expert third-party supplier to reduce costs, or changing the way your organisation operates, such as switching to digital marketing, to slim down your spending and release funds for your energy costs.

Implement Energy-Saving Technologies

A range of energy-saving technologies can be incorporated into modern manufacturing plants to reduce demand and reliance on fossil fuels, thereby cutting expenditure. While an initial outlay will be required, the long-term savings for your business can be attractive – plus, you’ll be able to promote your brand as one that is committed to eco-friendly practices. Common energy-saving technologies include:

- Solar panels

- Power factor correction capacitors

- Voltage optimisation units

- LED lighting

- Equipment timers

Contact Hone-All For Expert Outsourced Machining

We all like to keep as much in house as possible, but if you need an alternative solution, by outsourcing your CNC honing, deep hole boring, and drilling to Hone-All, we can help you save time, money and reduce your demand for energy during these challenging times.

To request a free, no-obligation quotation, please call us on 01525 370666 or send us a message.

-

Making The Most Of R&D Tax Relief For Manufacturing Businesses

1 November 2022Research and Development (R&D) tax relief can transform the way your manufacturing business operates, by providing financial incentives for investing in innovation. For businesses keen to enhance their research and development to achieve growth, R&D tax credits are an invaluable way to inject cash into the organisation and address some of the challenges facing manufacturers today.

In this article, we discuss how R&D tax relief works, who is eligible, and how you can make the most of the scheme.

How Does R&D Tax Relief Work?

Developing new products or processes and improving current ones is fundamental to success in manufacturing. Businesses who doggedly stick with so-called tried-and-trusted techniques often find that they are overtaken by their competitors who can produce superior quality goods for a lower price and in a quicker time.

By investing in process improvements and innovation, eligible businesses can submit an R&D tax credit claim for a reduction in corporation tax or a cash payment. While R&D tax credits are available for a wide range of sectors, they are especially well-suited to the manufacturing industry because it invests heavily in innovation – particularly within SMEs. R&D tax relief is available for the last two accounting periods if you are claiming it for the first time.

Who Is Eligible For R&D Tax Relief?

To qualify for Research and Development tax credits, manufacturing businesses must:

- Be registered as a UK limited company that pays Corporation Tax (CT).

- Have conducted qualifying research and development and

- Have invested money in R&D projects.

Documented the costs and time associated with the R&D activities.

What Can You Apply For – In Plain English!

The process needs to be that you: -

- Looked for an advance in science and technology – including an improvement to, or expansion of, existing technology.

- Had to overcome uncertainty.

- How you tried to overcome this uncertainty.

- Could not be easily worked out by a professional in the field i.e., is not already proven/known.

And the projects do NOT have to be successful to include them!

How Can You Make The Most Of Your R&D Tax Relief?

While any cash payment or reduction in CT will benefit your business, R&D tax relief is most effectively used to combat some of the specific challenges facing the manufacturing industry. This includes, but is not limited to, investing in innovations that:

- Manage supply chain disruptions to reduce lead times and ensure that customers’ orders can be fulfilled quickly.

- Address labour shortages, thereby boosting productivity and securing your business’s place in its sector.

- Achieve greater operational efficiency to improve product margins and cut costs.

- Invest in green technology, to reduce demand on fossil fuels, reduce energy expenditure, and improve your reputation as a credible eco-friendly business.

Speak To Us

If you’d like to find out more or join the conversation about R&D in the UK manufacturing sector, feel free to connect with me on LinkedIn, Andrea Wilson or send us a message through our website!

-

Hone-All’s Director Talks About Manufacturing And The Need For A ‘Minister of Manufacturing’ On GB News

3 October 2022As Liz Truss settles into her new role as Prime Minister, promising that the UK can ‘ride out' any post-pandemic turbulence (we agree with her on this, at least!), now is the ideal time for the Government to take decisive action to bolster perceptions of manufacturing and address the skills shortage that is affecting the industry at present.

Director of Hone-All Precision, Andrea Wilson, appeared on GB News last month to discuss the main issues affecting manufacturing SMEs as we enter the final quarter of 2022.

The Importance Of Investment

‘It always hurts,’ Andrea said with reference to the Bank of England’s decision to raise the UK’s interest base rate, but she emphasised the need to bring inflation under control to stabilise the nation’s economy. Rising interest rates will affect manufacturers’ investment decisions, especially given the high cost of equipment, so a long-term strategy focused on annual investment allowances and the super-deduction would help to offset the effects.

Changing Negative Perceptions

Faced with the suggestion that manufacturing has been ‘out of fashion’ with politicians for decades, Andrea wholeheartedly agreed, citing her efforts over the last 25 years to dispel negative perceptions of the industry. Modern manufacturing, she said, is ‘light, bright, and hi-tech’ but the industry isn’t prepared to ‘shout out enough’ about itself – even though it produces huge volumes of components that are essential to everyday use.

More Targeted Support

The manufacturing sector, Andrea argued, does not need ‘more support’ but ‘better use of the support that is there and easier access to it.’ This would help to overcome common problems, such as the lack of training facilities for engineers in the use of modern engineering equipment. Central to this would be the appointment of a dedicated Minister for Manufacturing.

‘We need a minister, or we need a voice for SMEs,’ Andrea explained, citing the postcode lottery for support for local businesses, and the lack of resources that prevent Local Enterprise Partnerships (LEPs) and Chambers of Commerce from delivering targeted support where it is most needed. Many SMEs don’t hear about the support on offer; for example, in a survey of SMEs conducted by Make UK, most had only heard about three of the 15 support schemes available. It’s not, Andrea explained, that LEPs and Chambers of Commerce lack the expertise, but that they are unable to publicise all relevant information to hundreds or thousands of manufacturing SMEs in their locality.

Better targeted support, delivered in the right way to the right places, as part of a long-term strategy, would enable manufacturing businesses to increase productivity without necessarily employing even more people.

Contact Hone-All Today

At Hone-All, we’re at the forefront of the manufacturing sector, with an unfailing commitment to high-quality, collaboration, and cost-efficiency.

To find out more about our services, please get in touch on 01525 370666 or drop us an e-mail on sales@hone-all.co.uk

-

Without A Strong UK Manufacturing Sector, You Can't Have A Strong UK Economy

3 October 2022In advanced capitalist economies like the UK, countries are judged on their economic strength. A healthy economy can help to bring jobs, raise living standards, improve public services, and promote social stability. But have we lost sight of what really matters in maintaining strong and stable economic growth?

GET IN TOUCHA few generations ago, industrial manufacturing was dominant in the UK. Since then, however, innovations in the financial and service sectors have seemingly taken precedence in national concerns, but manufacturing hasn't gone away. UK manufacturing persists among SMEs and has great potential for technological innovation and job creation.

So, shouldn't we be paying more attention to the economic benefits of a strong manufacturing sector?

Banking And Services Are Not Enough

In the last 40 years, UK banking has expanded massively. During the country’s EU membership, successive governments were happy to ‘outsource’ manufacturing capabilities to EU partner countries such as Germany, while specialising in financial services as the ‘money house of Europe’. There's no denying that banking remains a highly lucrative sector. However, post-Brexit, questions exist about its stability and capability of providing a sound basis for economic growth, especially since the 2008 financial crisis.

Since the decline of heavy industry in the UK, the service sector has also seen a big rise, and it is now the largest single contributor to UK GDP. However, the service sector alone is not enough to sustain the UK's economy and there are worries that it may not provide the stability and skills development needed to maintain consistent growth. Overreliance on services could leave the UK at the mercy of international trade and global contingencies, as we have seen acutely with the recent crises and supply chain disruptions caused by Covid and the war in Ukraine.The Importance Of UK Manufacturing

99% of the UK's economy is made up of SMEs, and with large-scale industry now mostly off-shored, this includes the majority of manufacturers. But too often, manufacturing is overlooked in political decision making, hidden away in industrial estates or backyard workshops. This is despite the fact that the UK's manufacturers are still producing many components that we rely on in everyday life. Indeed, though it's not as large as it once was and its composition differs, the UK's industrial sector is still the ninth-largest globally.

The global disruptions caused by Covid have been something of a wake-up call for the UK's economy. As globalisation contracts, at least temporarily, it seems we cannot rely on international trade and logistics to keep our essential services and commodity availability alive. Indeed, during the pandemic, it was the UK's SMEs who stepped up to the mark to provide ventilators, pharmaceutical products, PPE and other necessities. This kind of adaptability helped us to get through the worst of the suspensions in international trade.We Need To Support UK Manufacturing

It makes sense, therefore, for political decision makers to support UK manufacturing, lessening the problems of international supply chains and looking to promote economic and environmental sustainability.

A thriving manufacturing industry not only provides useful products with simpler supply chains.

It also provides jobs and apprenticeships for youngsters looking to make their mark. Investment in UK manufacturing can help to provide long-term stability for the UK, boosting technological innovation and home-grown talent.

It would be wise for the UK to have a dedicated Minister for Manufacturing, to champion the interests and benefits of our manufacturing sector – both nationally and internationally.In times of global contraction, the more we invest in UK manufacturing, the less we depend on international trade. And while the effects of international disruptions cannot be entirely banished, they can certainly be mitigated by a strong, and recognised, UK manufacturing sector.

Our Director, Andrea Wilson, is the figure head of Support UK Manufacturing is calling for more recognition of SME manufacturers, improved (not increased) support and a return to in-house apprenticeship training with tax incentives to support this. Visit www.supportukmanufacturing.co.uk for more information.

-

Time To Level Up And Reverse The Historic Decline In Manufacturing

3 October 2022Earlier this year, Labour leader Keir Starmer promised that his party would transform British manufacturing if elected to govern the country, citing a reduction in funding and the loss of over 93,000 jobs since 2010. Needless to say, pledges of this nature are cheap and easy to make in politics.

However, and in contrast, Germany has recruited one million extra manufacturing workers in the same period and, free of the logistical and economic restraints posed by Brexit, the country’s automotive sector has consistently outperformed that of the UK.

Contact The Team at Hone-All Today

The current government has made much of its Levelling Up agenda, and we look forward to seeing how the Prime Minister’s successor intends to pursue this agenda in the remaining years leading up to the 2024 election. With this in mind, what lessons can be learned from the way that Germany has managed its manufacturing sector under various centre left and centre right governments over the past 10 years?

Mittelstand: The Heart Of Germany’s Economy

Germany has enjoyed a reputation for engineering excellence for many years, but its success is not simply a result of good fortune. Over 99 per cent of the country’s small and middle-sized

enterprises (SMEs) belong to the Mittelstand, an association of over one million companies that is a powerful engine for the German economy:- Employs over 20 million people.

- Accounts for more than 30 per cent of exports.

- Responsible for over half of Gross Domestic Product (GDP).

- Provides vocational training to approximately 82 per cent of apprentices.

- Germany’s success as a manufacturing powerhouse is largely driven by the Mittelstand, yet many of its SMEs occupy a low profile.

What makes the Mittelstand effective and could the UK benefit from adopting a similar strategy?

A Razor-Sharp Focus

Most well-known manufacturing companies have diversified from their core business, yet the Mittelstand comprises a vast number of SMEs who, collectively, account for the majority of Germany’s trade surplus. Mittelstand manufacturers tend to have a concentrated focus on their core services, offering highly specialised and customised products that meet their customers’

exacting specifications.

A Commitment To EntrepreneurshipMittelstand companies are highly innovative, sometimes with strict policies not to discuss the ingredients of their success with the media. They are also backed by the Federal Ministry for

Economic Affairs and Climate Action, who support challenging SMEs to stay innovative, vibrant, and strong. The German government is working on many fronts to strengthen the Mittelstand and increase its competitiveness, with job creation central to its success.

A National System Of Vocational Training

The success of Mittelstand depends heavily on investment in vocational training, which is globally renowned for its quality. By combining workplace training with classroom theory, SMEs can recruit highly skilled and committed staff. The Mittelstand workforce is extremely stable and loyal, with a turnover rate of only 3 per cent.

Could The UK Foster The Spirit Of Mittelstand?With a proud history of manufacturing success and an increasing thirst for reshoring to resolve problems in global supply chains, the UK is perfectly positioned to seize upon the Mittelstand’s

success to transform the industry at home.

At Hone-All, we have long argued for direct action to reverse the fortunes of UK manufacturing. A change in leadership in Downing Street is an ideal opportunity to create a new position for a

Minister for Manufacturing, so that the interests of SMEs can be given proper representation. By promoting the manufacturing industry at home and abroad, a prominent ministerial role would

help to erase the negative connotations associated with the sector and implement strategies to make manufacturing more resilient, productive, and attractive.

Contact Hone-All Today

To find out more about our specialist services, and our campaign for Government representation for SMEs, please get in touch today on 01525 370666 or visit www.hone-all.co.uk -

Does A Lack Of Advanced Digital Technology Harm UK Manufacturing?

1 September 2022Despite the plethora of digital processes in the modern economy, recent research indicates that 96% of UK manufacturers feel there has been an underinvestment in digitisation in their sector.

The survey results span a diverse range of areas, from aerospace and defence to medical instruments and electronics, but the sentiments were consistent. Survey respondents overwhelmingly felt that overreliance on legacy technologies was harming the UK's manufacturing industries' prospects.

So, what exactly are the problems with digital underinvestment, and what can be done to improve the sector's performance and reputation?

The Trouble With Digital Hesitancy

Perhaps shockingly, given the wealth of digital solutions available for ERP, CRM and other applications, many SME manufacturers are still using spreadsheets to process their data. These legacy mechanisms are clunky and error-prone, lacking the verification and algorithmic efficiencies afforded by dedicated software solutions. Their unsuitability for the task often leads to spiralling ad-hoc solutions that are usually complicated and brittle. Above all, they are slow and inefficient for business.Contact us

Outdated systems also make it hard to manage supply chains, and accurately monitor performance – increasingly crucial factors for businesses hit by disruptive world events and spiralling costs.They also make it difficult to track and share data. Without accountability and monitoring, it can be hard to assess the process performance or business initiatives, and forward planning becomes less precise.

Business Results Of Inadequate Technology

Talent is a company's most vital asset. If companies cannot attract it, they risk missing business innovations and expansion opportunities. But excess reliance on legacy technology makes it increasingly challenging to attract the next generation of talent. These young innovators are often drawn to companies and sectors that embrace modern systems and technological change, not those stuck in the past.

Using The Appropriate ToolsFor success, businesses must use the tools appropriate to the task. Transition to advanced digital technology won't happen overnight, but companies should waste no time in creating a digital development strategy that covers the next 5-10 years. As a first step, proper control of business data is vital and should come before upgrading manufacturing technology.

For an SME of our size, we find @RedantProductionControl the perfect solution.

It’s a powerful and professional production control system which is user friendly and simplistic in its functionality, and it manages our entire operation.

The comprehensive list of fantastic features and applications help us to not only adhere to EN 9100 & ISO 9001 but ensures we have traceability to Rolls Royce standards; monitoring and measurement of processes using Real Time Data Collection enabling accurate costing and financial performance analysis; and every possible KPI can be reported upon via Crystal Reports.

Yes, there are more well-known and complex systems out there, but for an SME of our size, we, and our team, find this to be the perfect solution to help us remain professional, proficient, and profitable.

Contact The Team at Hone-All Today

It’s also a system which develops alongside its users.

Any ideas for improvements are implemented free of charge as long as they benefit the other users. Bespoke tailoring is available through a variety of switches to enable you to turn on or off certain features which may not be appropriate or applicable to your business.

It’s this type of adaptability, flexibility and user friendliness which allows us to save time, reduce costs and yet compliments and enhances our continuous improvement programme.

It’s also really competitively priced, and to make it easier for SMEs to implement, Redant will offer a FREE data conversion service for anyone using a compatible system – plus a 20% trade-in discount – until the end of this year! This ensures no downtime, no resource for data input and means you can be in full control of our business, and its performance, within a few short days!

For more information, contact @AndreaWilson at andrea@hone-all.co.uk or Redant Production Control directly at sales@redantsoftware.co.uk

-

2 Years After Brexit, British Manufacturing Hasint Found Its New Normal

5 August 2022The issue of Brexit has dominated British politics for more than six years. Despite claims of "getting Brexit done", several issues remain unresolved and the repercussions for the UK economy have been quite significant – although we mustn’t forget how the

picture has been enormously skewed by the impact of the pandemic. Positives can of course be found in the UK's new situation in the world, especially in terms of long-term, as yet unrealised potential, but two years after the official exit date from the EU, British manufacturing is yet to achieve its ‘new normal’.

Customs Declarations

According to Lucinda O’Reily from The International Trade Consultancy negotiators on both sides had hoped to avoid this situation – but British importers and exporters now need to complete customs paperwork for European trade that was unnecessary with EU membership. (Even many Leave advocates suggested remaining in the EEA post-Brexit, with a similar trade relationship to Switzerland or Norway.)One of the major post-Brexit challenges for manufacturers is to get to grips with HS or commodity codes. These codes classify goods and specify the relevant tariffs for import or export. From these, duties and quotas, as well as licensing and labelling requirements are determined. Incorrect codes cause delays at ports and reputational damage, and with updates every 5 years, companies will need to stay on their toes.

Similarly, Incoterms, or International Commercial Terms, have become an issue that UK traders with the EU now need to be familiar with. These specify the obligations, risks and costs associated with the sale and purchase of goods. They're mainly used in transportation, to determine who is responsible for carriage, insurance, documents, security and so on.

The Northern Ireland Protocol

A particularly difficult snag in the Brexit process, and an ongoing source of dispute, is the Northern Ireland protocol. The island of Ireland now contains the EU's only land border with the UK, and yet for years, an open border between the Republic and the North has helped to quell tensions in the region. For that reason, the NI protocol was put in place in the Brexit agreement to allow goods produced in Northern Ireland to be sent across the border without customs formalities. However, to the inconvenience of GB exporters and the consternation of many in the Unionist community, this means a de facto border within the UK, in the Irish Sea.

The UK government has therefore proposed to unilaterally override the protocol, which would set up red and green channels for export (for ROI and NI destinations respectively). It would also allow British exporters to NI to choose between EU or UK standards, end EU control over state aid and VAT, and curb the oversight of the European Court of Justice in Northern Ireland. It would also ratify the UK's ability to make further changes to the protocol at will. Needless to say, this has soured relations with the EU further and introduced more uncertainty into future trading arrangements for UK manufacturers.

Other Problematic Factors

On top of the difficulties of Brexit, the Covid-19 pandemic has had a huge global impact, and for manufacturers, particularly severe disruptions to supply chains, interrupting trade for significant periods. And that's not the only headwind facing UK manufacturers. HMRC is transitioning to a new system for handling customs entries. The move from 'CHIEF' to 'CDS' will require significant staff training to meet both sets of requirements until the transition is complete. Failures will result in delayed transit and interrupted business. Add to this the problem of inflation and uneven economic recovery and it seems that, unfortunately, the business landscape for manufacturers looks rocky for some time yet.All this isn’t to say that there isn’t room for optimism among UK manufacturers. There is.

The sector has weathered far worse storms in the past and post-lockdown, many businesses are experiencing enormous growth. The best response to uncertainty is to build greater resilience and flexibility into supply chains and business systems. This allows manufacturers to absorb shocks more effectively and respond quickly to new opportunities and market conditions.

If you want to discuss this topic further, contact Lucinda O'Reilly from The International Trade Consultancy. Lucinda very kindly contributed to this article and is the founder of The International Trade Consultancy, providing practical, customised, and easy-to-follow solutions to organisations importing and exporting problems.

Here at Hone-All, the demand for our excellent quality and specialist services has resulted in increased demand for exports and the subsequent complexities involved. @LucindaO'Reilly AMIEx helped us find the simplest and easiest way to navigate the issues and as a result, has helped us exploit more opportunities than we would have.

To find out why international customers are selecting Hone-All to be their supplier of choice, contact us today on 01525 370666.

-

A Short 'How To' Guide For Requesting Deep Hole Drilling Quotes

5 August 2022Deep hole drilling is a machining technology designed to create bores that have high length-to-diameter ratios that could not be produced with conventional drilling techniques.

At Hone-All, we combine the latest deep hole drilling technology with exceptional standards of workmanship and experience to meet our customers’ requirements for holes up to 2,500mm in length and between 2mm and 25mm in diameter.

Our innovative deep hole drilling equipment ensures a consistently high standard of machining, so we can meet short timescales within budget.

With an accuracy of 0.001” per 1” drilled, our deep hole drilling promises the incredible precision required in a range of demanding industries, including:

- Aeronautics and defence

- Oil and gas production

- Hydraulics

- Medical

- Motorsports, including F1

If you would like a quote for deep hole drilling for your next engineering project, what information do we need from you – and why?

Information/Parameters We Need To Quote For Deep Hole Drilling

- The material specification – this is essential to ensure accurate quoting as material properties differ, as do the speeds and feeds required to machine them efficiently.

- Outside diameter – we need this to assess which machine the component can be held on as well as to ensure we have a suitable wall thickness to ensure the drilling process can be completed safely.

- Inside diameter – this is required to ensure we have tooling available, as although we have a vast range in stock, certain materials such as Inconel, may require specialist tooling, as do blind bores with specific forms at the base.

- Overall length – as with the first two, these are required for tooling and machine capacity decisions.

- The bore type – i.e., is it a through bore or blind bore? If it is a blind bore, is a specific form required such as a flat bottom or particular radius at the base? Standard deep hole drilling leaves a sharp W shape at the bottom of the bore. Any other form can increase your unit cost due to either requiring specific drill grinds or bespoke drill heads.

- The depth tolerance – if you require a blind bore, we need to know the tolerance required on the bore depth. As long as there is excess material on the length, we can “back-face” to achieve tighter tolerances on depths.

- The bore tolerance – bore tolerance is a major factor when quoting the deep hole drilling process. If the tolerance is below the industry standard of ±0,1mm, a honing process may be required.

- Any surface finish requirement – in addition to the bore tolerance, this is needed to ascertain whether we have to add a honing operation.

- T.I.R. or Straightness requirements – we need to know these as even though we may be only carrying out an initial gundrilling or deep hole drilling operation, we need to ensure there is sufficient material to be turned off to correct any drill wander. Industry standard for drill wander is 1mm per 1 metre or 0.001” per 1” drilled.

Hone-All: Precision, Reliability, And Integrity

If you are looking for a trustworthy precision machining company that puts its customers’ needs first, talk to Hone-All today.

By collaborating with us, you benefit from:

- A tailored approach to meeting the needs of your project, within your timescales.

- A commitment to providing unrivalled excellence and reliability.

- Our investment in the latest cutting-edge drilling technology and a programme of upskilling our talented team.

- A clear outline of costs and timescales so you can plan and budget on your production line.

- An open, friendly approach at all stages of the process.

To find out more about our deep hole drilling services, please call 01525 370666 or request a quote and our team will be in touch.

-

What You Should Know Before You Ask For A CNC Gundrilling Quote

1 August 2022When the limitations of conventional drilling pose an obstacle to your project, CNC gundrilling provides a cost-effective and reliable way to drill holes with a diameter to depth ratio in excess of 100:1. CNC gundrilling combines Computer Numerical Control (CNC) technology with high-quality, carbide gundrill tools to create holes between 3mm and 28mm in diameter, up to 2,500mm deep.

Hone-All have a range of CNC gundrilling machines at our facility in Leighton Buzzard, which deliver highly accurate results in the shortest possible time. Ideal for straight drilled channels and precise round holes, our CNC gundrilling services can meet high tolerance parameters to ensure the greatest precision, with no need for time-consuming or expensive secondary finishing.

Industries We Serve

CNC gundrilling is suitable for a range of materials, including high grade alloys, stainless steels, aluminium, titanium, and thermoplastics. Industries we work with include:

- Injection Moulding

- Aerospace

- Medical technology

- Hydraulics

- Petrochemicals

- Motorsport

Information/Parameters We Need To Quote For Deep CNC Gundrilling

- The material specification – this is essential to ensure accurate quoting as material properties differ, as do the speeds and feeds required to machine them efficiently.

- Outside dimensions – we need this to assess which machine the component can be held on as well as to ensure we have a suitable wall thickness to ensure the drilling process can be completed safely.

- Inside diameter of the bores required – this is required to ensure we have tooling available, as although we have a vast range in stock, certain materials such as Inconel, may require specialist tooling, as do blind bores with specific forms at the base.

- Overall length – as with the first two, these are required for tooling and machine capacity decisions and help us calculate the weight of the components.

- The bore type – i.e., is it a through bore or blind bore? If it is a blind bore, is a specific form required such as a flat bottom or particular radius at the base? Standard deep hole drilling leaves a sharp W shape at the bottom of the bore. Any non-standard form can increase unit cost due to the requirement for specific drill grinding or bespoke tooling requirements.

- Bore quantities and positional details – CNC gundrilling is most often utilised on parts which are not being drilled on centre, or holes, or multiples of holes, are required in fully machined blocks / milled sections. To quote accurately, we need the number of bores required, the position of them, and the positional tolerances required in relation to each other and the outside diameter.

- The bore tolerance – bore tolerance is a major factor when quoting the CNC gundrilling process. If the tolerance is below the industry standard of ±0,1mm, a honing process may be required.

- The depth tolerance – if you require a blind bore, we need to know the tolerance required on the bore depth. As long as there is excess material on the length and it is a round bar, we can “back-face” to achieve tighter tolerances on depths.

- Any surface finish requirement – in addition to the bore tolerance, this is needed to ascertain whether we have to add a honing operation.

- T.I.R. or Straightness requirements – we need to know these as even though we may be only carrying out an initial gundrilling or deep hole drilling operation, we need to ensure there is sufficient material to be machined down to correct any drill wander. Industry standard for drill wander is 1mm per 1 metre drilled.

Why Choose Hone-All For CNC Gundrilling?

At Hone-All, we offer quality-assured CNC gundrilling that is guaranteed to deliver the tolerances and accuracy you need for your next engineering project.

With decades of experience with a wide range of projects, we have the skills, knowledge, and tools to achieve exceptional results no matter how challenging the requirement. We value our partnerships with our customers and deliver a bespoke service that consistently meets their needs, on time and within the agreed budget.

To find out more about our CNC gundrilling services or to request a free, no-obligation quotation, please call us on 01525 370666 or send us a message.

-

10 Things You Should Include When Requesting A Quote For CNC Honing

1 August 2022Honing is a machining process that uses an abrasive stone or emery paper to the surface of a workpiece along a controlled path, to improve its geometric form or create a specific surface finish.

At Hone-All, our expert CNC honing services utilise the latest Computer Numerical Control (CNC) technology to deliver high-quality results. We can hone round bores within a tolerance of ±0,005mm between 1.5mm and 500mm although the tolerance offered does increase relative to the bore size.

Our CNC honing, which meets international quality standards, including ISO 9001 and BS EN 9100, is carried out at our facility in Leighton Buzzard, enabling us to carefully manage the entire process for exceptional quality and performance.

Areas Of Specialty

We have extensive experience of providing CNC honing services to businesses in the UK and overseas industries in a variety of precision manufacturing sectors:

- Energy production

- Printing and packaging

- Hydraulics

- Aerospace

- Defence

- Motorsport / Automotive

- Medical instruments

Information/Parameters We Need To Quote For CNC Honing

- The material specification – this is essential to ensure accurate quoting as material properties differ, as do the speeds, feeds and products required to hone them efficiently.

- Outside diameter – we need this to assess which machine the component can be held on.

- Inside diameter – this is required to ensure we have tooling as honing tool sizes are available relative to the length of the bore diameter requiring honing.

- Overall length – as with the first two, these are required for tooling and machine capacity judgements.

- The type of bore required i.e., through, blind – if blind, is there a relief as honing tooling will never achieve full depth due to the design of the tools themselves. Alternatively, is it a tandem, keyway or serrated bore? All of these add complexity to the process, often requiring specialised tooling.

- The bore tolerance – bore tolerance is a major factor when quoting the honing process as the tighter the tolerance, the harder it is to achieve, depending on the bore diameter.

- The surface finish requirement – this is needed to ensure we are quoting the correct finish for the appropriate application. Unbelievably, you can supply a finish which is TOO good for certain applications.

- Roundness, straightness or cylindricity specifications – these are required to ensure we can meet all required parameters.

- Stock removal – this is essential to guarantee we are quoting you the best possible price as the more stock, the more time the process takes. If there is excessive stock, we also have to factor time for the material to “cool” as the bores can shrink back after they have heated during the honing process.

- Whether any bespoke gauging is available from you as highly specialised gauging can be extremely costly and can sometimes render the job not financially viable if only a small volume is required.

Why Choose Hone-All For CNC Honing?

However complex your engineering project, our precision engineering experts possess the skills and knowledge to ensure our CNC honing delivers the highest quality standards. By choosing Hone-All, you can be assured of:

- A bespoke approach to your engineering project that takes account of your specific needs.

- An unwavering commitment to excellence, safety, and reliability.

- Decades of experience in the field of CNC honing that enables us to tackle any project.

- High-quality results driven by our investment in cutting-edge CNC technology.

- A clear explanation of costs and timescales.

To find out more about our CNC honing services, please call 01525 370666 or request a quote and our team will be in touch.

Contact The Team at Hone-All Today

-

What You Need To Provide For A Deep Hole Boring Quote

1 August 2022Deep hole boring is a machining process in which holes are drilled with a depth to diameter ratio in excess of 100:1. The process is used to create bores in a range of materials, from aermet to aluminium to superalloys, and has applications in a variety of industries, including:

- Oil and gas production

- Hydraulics

- Aerospace and defence

- Mold making

- Heavy industry

At Hone-All, our deep hole boring services utilise cutting-edge technology to achieve exceptional precision and close tolerances. With decades of experience in the field, we deliver outstanding results for applications in any field of industry which requires precision bores greater than 20mm in diameter.

Information/Parameters We Need To Quote For Deep Hole Boring

- The Material Specification – this is essential to ensure accurate quoting as material properties differ, as do the speeds and feeds required to machine them efficiently.

- Outside Diameter – we need this to assess which machine the component can be held on as well as to ensure we have a suitable wall thickness to ensure the drilling process can be completed safely.

- Inside Diameter – this is required to ensure we have tooling available, as although we have a vast range in stock, certain materials such as Inconel, may require specialist tooling, as do blind bores with specific forms at the base.

- Overall Length – as with the first two, these are required for tooling and machine capacity decisions.

- The Bore Type – i.e., is it a through bore or blind bore? If it is a blind bore, is a specific form required such as a flat bottom or particular radius at the base? Standard deep hole boring leaves a shallow W shape at the bottom of the bore. Any other form can increase your unit cost due to either requiring bespoke drill heads or a process bore with a single point boring operation to create the form.

- The Depth Tolerance – if you require a blind bore, we need to know the tolerance required on the bore depth. As long as there is excess material on the length, we can “back-face” to achieve tighter tolerances on depths.

- The Bore Tolerance – bore tolerance is a major factor when quoting the deep hole drilling process. If the tolerance is below the industry standard of ±0,25mm, a honing process may be required.

- Any Surface Finish Requirement – in addition to the bore tolerance, this is needed to ascertain whether we have to add a honing operation. Industry standard for deep hole boring would be 3,2µ or 250 CLA.

- T.I.R. Or Straightness Requirements – we need to know these as even though we may be only carrying out an initial first or second stage process boring operation, we need to ensure there is sufficient material to be turned off to correct any drill wander. Industry standard for drill wander is 1mm per 1 metre or 0.001” per 1” drilled.

Why Hone-All Is Your First Choice For Deep Hole Boring

At Hone-All, we take pride in helping our customers achieve outstanding machining results at a cost-effective price. By investing in the latest deep hole boring technology and the professional development of our skilled engineers, we deliver precise and reliable results that accurately meet the needs of every project.

All our deep hole boring services are completed in-house at our advanced facility in Bedfordshire. With an unshakable commitment to achieving excellence in our machining, underpinned by our ISO 9001 and BS EN 9100 accreditations, Hone-All is the first choice for your deep hole boring needs.

Contact Us To Find Out More

To find out more about our deep hole boring services or to request a free quotation, please call 01525 370666 or contact us here.

-

“Enginuity”: A Smarter Way To Attract And Train The World's Best Engineers

4 July 2022To be the best in your field as a business, you must attract the best talent.

Despite rapid innovations in automation technology in recent years, highly skilled and knowledgeable engineers remain the lifeblood of all successful engineering companies. However, the UK faces a significant ‘skills shortage’ in forthcoming years that threatens to undermine its position as a global leader in manufacturing, with the roots of the problem emerging as far back as primary education.

A 2018 report from The University of Manchester and the Royal Academy of Engineers highlighted the annual 20,000 shortfall in graduate engineers the industry faces, with a lack of engineering teaching in primary schools a key factor. The report argued that primary school teachers need more funding and support to embed engineering in the curriculum, with a focus on structured play and tinkering to develop pupils’ enthusiasm for real-life challenges and collaborative experiences.

Now, Enginuity, who create practical training solutions for individuals, schools and colleges, and employers, are harnessing young people’s interest in Mojang Studio’s award-winning Minecraft video game to teach the must-have engineering skills that are the basis for a successful career in the industry.

Minecraft: Engineering In Practice

There are few parents who haven’t heard of Minecraft. The world’s best-selling video game, which has sold over 238 million copies, enables players to create and explore a blocky Lego-style three-dimensional world, to extract raw materials, craft tools and objects, and construct buildings. With an easy-to-use interface, it’s an incredibly popular platform among children, who can quickly master the skills, making Minecraft the ideal vehicle for teaching key skills in problem-solving and collaboration.

Enginuity have seized on the popularity of Minecraft to bring engineering alive in an engaging and memorable way. Their award-winning Skills Miner games and practical lessons are mapped to the 12-14 school curriculum and give young learners the chance to engage in engineering challenges, with a focus on:

- Solving practical problems

- Working independently or in teams

- Achieving sustainability

- Working to a defined budget

- Learning about engineering jobs from engaging avatars

Enginuity’s Minecraft games are free-to-play in school or at-home on Minecraft Education Edition and are a great way to enthuse young people about engineering in an appealing virtual world with which they can readily identify.

Play now at https://enginuity.org/innovation-lab/skills-miner/

Hone-All: Passionate About Upskilling The Engineers Of The Future

At Hone-All, we are passionate about shaping tomorrow’s engineers, today. We recognise that with the right investment in education and skills, from primary schools to the shop floor, we can play a key part in developing a generation of talented engineers who will grow the UK’s reputation as a manufacturing powerhouse and protect local communities through employment.

To find out more about our involvement in engineering initiatives or our innovative services, please get in touch.

-

Manufacturing UK Skills Gap? The National Manufacturing Skills Task Force Is The Answer!

4 July 2022Many UK sectors face labour shortages as the impact of Brexit and the global pandemic continue to bite but, in manufacturing, the skills gap is particularly acute. A shortage of specialist skills threatens to disrupt manufacturing output and supply chains in an already uncertain trading landscape.

Despite this, the future of UK manufacturing is bright, so long as immediate, and sustained action is taken to address the skills shortage. The UK features in the top ten of global manufacturing economies, delivering over £185 billion of output between 2020 and 2021. Over 2.7 million people are employed in the manufacturing sector, with salaries over 12+ per cent higher than in the rest of the economy. Britain’s reputation as a world leader is manufacturing is well-established and irrefutable, so capitalising on this by closing the skills gap is vital to strengthen the industry further and generate valuable new trade with global partners.

Addressing The Skills Shortfall

2020 saw a major alignment of the many organisations that represent manufacturers in the UK. In August 2020, an open letter was set to the Secretary of State for Education, highlighting the skills shortage that all sectors of manufacturing face in the UK.

This was the first time that representatives from across manufacturing, both employer bodies and trade unions, have united to assert their commitment to working collaboratively to address the problem. Recovering from the effects of Brexit and Covid-19 is critical to the future of the industry, and it is jointly recognised by manufacturing associations that targeted action is required to ensure employers have access to talented and highly skilled staff if they are to flourish in the coming years.

The National Manufacturing Skills Task Force

Formed by the original 16 signatories of the August 2020 open letter, the National Manufacturing Skills Task Force membership has increased to 21 organisations and continues to grow. The task force is a critical step towards tackling the skills crisis. By offering a unified approach, a strong voice, and strategic leadership, the task force aims to:

- Become a key intersection between employers, individuals, and the Government.

- Offer strategic leadership on areas of common interest and recommend proposals to the Government for policy or investment.

- Support education providers in the provision of training and education so that learners develop the skills required by manufacturing employers.

- Communicate the importance of manufacturing to a range of parties.

- Develop strategies for the retention of talent and skills in the sector.

- Share best practice and resources to enable manufacturers to attract skilled workers.

For more information about the National Manufacturing Skills Task Force visit www.manufacturingskills.org

Hone-All: A Champion For The Manufacturing Industry

At Hone-All, we are passionate advocates for the manufacturing industry and work hard to give small and middle-sized enterprises (SMEs) a voice in the challenging post-Brexit and post-pandemic world. Therefore, we welcome and celebrate the formation and work of the National Manufacturing Skills Task Force.

We have campaigned on a number of important issues, such as the appointment of a dedicated Minister for Manufacturing who would, in our view, provide better representation for manufacturing SMEs, restructure the failing support system and shape Government policy to give British businesses a more competitive edge.

We welcome enquiries, either about our involvement in manufacturing initiatives or our extensive range of precision engineering services, so please get in touch today to find out more.

-

Why Hone-All Are Taking Part In Manufacturing Day - And What To Expect From The Day

4 July 2022Launched by MAKE UK, 7th July 2022 is National Manufacturing Day, a chance for schools, colleges, and communities across the country to enjoy a ‘keyhole look’ into some of the nation’s most well-known companies.

Why A National Day For Manufacturing?

Despite its reputation for excellence, the UK’s manufacturing industry remains an unknown quantity at home. Negative perceptions, driven largely by lingering stereotypes and inaccurate reports in the media, are commonplace, with careers in engineering often portrayed as ‘only for men’, backbreakingly hard work, or poorly paid.

Of course, nothing could be further from the truth: the engineering and manufacturing industries are desperate for highly skilled and talented people, for whom lifelong, rewarding careers are on offer. Initiatives such as the National Manufacturing Day are crucial to give people from all walks of life an invaluable insight into what really goes on behind the closed doors of the nation’s factories and workshops.

What Will Happen On National Manufacturing Day?

Manufacturing businesses, including Hone-All, will open their doors so that students, teachers, careers advisors, and members of the public can see for themselves the job prospects on offer in an exciting and fast-changing sector. In particular, National Manufacturing Day is geared to give visitors more information about engineering careers, whether they are school leavers unsure where their future lies, or experienced workers seeking to reskill and pursue new challenges in their work life.

National Manufacturing Day will also provide a unique insight into the role the sector plays in local communities across the country, so that visitors can understand the importance of manufacturing to the fabric of the UK and how it provides the highly skilled and well-paid jobs necessary for the nation to compete on the international stage.

National Manufacturing Day is a unique opportunity for people from across the UK to get behind the scenes of success at many of the country’s most renowned and respected engineering companies.

On the day, visitors will be able to:

- See manufacturing in action, including the use of the latest technology to creative complex products.

- Find out more about how manufacturing companies operate and the roles and responsibilities of key staff.

- Learn about career opportunities in manufacturing in a range of specialisms including design, IT, product development, research, and logistics.

- Participate in fun and engaging hands-on activities.

- Take part in an informative virtual tour of facilities if an in-person visit isn’t possible.

Hone-All: Proud To Support National Manufacturing Day 2022

At Hone-All, we’re proud to play our part in making National Manufacturing Day a success.

We believe that our people are what drives our success, so we invest heavily in our team’s professional development and the latest technological innovations to deliver an unrivalled service for our customers. To find out more about our services, please get in touch today.

-

Let's Celebrate Manufacturing! How National Manufacturing Day Benefits All Of Us

1 June 2022For two centuries, the UK has been a global leader in manufacturing: the birthplace, not only of the Industrial Revolution, but also of some of the most well-known and iconic brands the world has seen.

Today, manufacturing continues to play a pivotal role in shaping the nation's economy. Employing over 2.7 million people, the sector contributes one-tenth of the UK’s Gross Domestic Product (GDP) and accounts for 53 per cent of the country’s exports.

Small and middle-sized enterprises (SMEs) in the manufacturing sector also safeguard local communities, providing highly paid employment and investing in infrastructure, so any initiatives that raise public awareness of the sector are crucial to futureproof it against the threat of cheap, and often inferior, overseas imports.

This summer, Hone-All is proud to play a part in the National Manufacturing Day, which takes place on 7th July 2022. What is the event and why is it important?

National Manufacturing Day: A Day Of Celebration

On 7th July, manufacturing businesses across the UK will be throwing open their doors to welcome students, teachers, and members of local communities, to give them a first-hand insight into the important work that they do.

Visitors will be able to see manufacturing processes in action, chat to staff about their roles, and find out more about the career opportunities on offer in a fast-moving and exciting sector. They will also learn more about how engineering companies support local communities and play a vital part in sustainability through employment and investment.

By throwing off the negative mantle that is so often portrayed through adverse media coverage, British manufacturing will showcase its achievements and potential, giving visitors from all walks of life a revitalised understanding of the sector.

Why National Manufacturing Day Is Important

National Manufacturing Day isn’t just a nationwide ‘open house’ for engineering businesses, but is a key strategy to re-educate the British public about the important role the industry plays in the economy and its potential for outstanding growth in years to come.

Despite its strong history, UK manufacturing is ranked only ninth in the world. Many school and college students know little about the sector and won’t consider forging a successful career in manufacturing, despite high salaries and long-term job security.

By opening the country’s factories and workshops to visitors, National Manufacturing Day aims to inspire the next generation of skilled workers and give the public a better understanding of the important role the sector plays in their lives.

National Manufacturing Day aims to:

- Alter the perception of manufacturing careers to increase uptake of engineering courses in schools and colleges.

- Increase the pool of talented workers, both aspirational young people and employed adults seeking to be reskilled.

- Promote an appreciation for the manufacturing industry to reinforce the need for more proactive Government support and intervention.

Contact Hone-All To Find Out More

At Hone-All, we will be playing an active part in National Manufacturing Day 2022, but we also welcome interest in our highly specialist precision machining services. To find out more, please get in touch today.

-

Why SMEs Are So Vital To Both The Economy And Society

3 May 2022SMEs are an integral part of the UK’s manufacturing landscape. Accounting for over 90 per cent of all manufacturing businesses, SMEs contribute 25 per cent of GDP each year and play a crucial role in the export of billions of pounds of goods to Europe and beyond.

Get my copy of the FREE Guide To Deep Hole Drilling, Boring & Honing Costs!Yet, surprisingly, manufacturing SMEs are greatly undervalued in society. Most people outside the sector don’t recognise the work that small manufacturing businesses complete or the substantial contribution they make to our everyday lives.

So, how are SMEs vital to both the UK economy and society?

Precision Engineering That Spans Every Part Of Society

Advanced technologies are an intrinsic part of our everyday life but, often, we don’t always see the highly specialised equipment that underlies them. From the exquisitely engineered medical devices that are essential to safe operations, to tiny components that are critical parts in commercial airliners and the cars we drive every day, precision engineering plays a vital role in many areas of our lives.

Few consumer devices are made entirely by a single manufacturer; instead, even large corporate manufacturers rely on specially machined components produced by a complex network of SMEs, without who the entire design and build process would cease.

A Steadying Hand During Times Of Crisis

The Pandemic demonstrated the vulnerability of global supply chains, resulting in worldwide shortages of many appliances, from gaming consoles to ventilators. Now, the war in Ukraine, accompanied by economic sanctions on Russia, is threatening production lines across the world.

During times of crisis, manufacturing SMEs can play a crucial role in fixing and bridging supply chain problems. When large manufacturing companies cannot fulfil orders directly, outsourcing precision engineering to SMEs can plug the gaps, ensuring that deadlines are met.

Career Opportunities For Young People

Job security is much sought after in modern society, particularly with rising utility costs and property prices. The Government’s expansion of its apprenticeship scheme was supposed to yield increased opportunities for school leavers to embark on a rewarding skills-based profession, with manufacturing offering competitive salaries and long-term stability for engineers. However, as Rishi Sunak alluded to in his Spring Statement, the Apprenticeship Levy and it’s processes need urgent review.

Unfortunately, even if the apprenticeship scheme offering is fixed, the public perception of engineering as a career option is still soured by negative and inaccurate connotations. Young people, influenced by misrepresentations of engineering in the media, often steer away from the profession; consequently, even at GCSE level, the number of students taking engineering as an option is dropping year-on-year.

Addressing The Future Of Manufacturing

SMEs already play a crucial role in the UK economy and society and, with the right investment and commitment from the Government, even more could be achieved in years to come.

- Government funding should be directed more incisively to areas of need to avoid misspending.

- Manufacturing SMEs should be lauded for their contributions to society: high levels of employment, job security, economic prosperity, and important innovations in all walks of life.

- Measures to protect SMEs in the future should be introduced, with greater guidance and more investment for training and skills development.

Find Out More

This article is based, in part, on a recent interview of our Director, Andrea Wilson by Miranda Birch, in which they discussed topics ranging from reshoring and apprentices, to bridging the skills shortage and gender imbalance in manufacturing.

-

Why UK SME Manufacturing Firms Aren't Given The Credit They Deserve

3 May 2022The UK has been a manufacturing powerhouse for nearly 200 years: the birthplace of the Industrial Revolution and a key player in defining some of the world’s most recognisable technologies. Most people, when prompted, could name several world-famous large UK manufacturers who have built their reputation on quality and service: Rolls Royce, BAE Systems, Jaguar Land Rover, and Bristan, to name a few.

Get my copy of the FREE Guide To Deep Hole Drilling, Boring & Honing Costs!

What is less well-known is the important role that small and middle-sized enterprises (SMEs) play in the country’s manufacturing industry. Often overlooked by political decision makers compared to the larger corporate entities, SMEs make significant contributions, not only to industry itself, but to their local communities in many ways, including employment, education, and investment in infrastructure.UK Manufacturing SMEs: The Facts

How influential are the UK’s manufacturing SMEs in 2022?

- In 2021, there were approximately 270,000 businesses in the UK’s manufacturing sector.

- Of these, less than 2 per cent were larger entities employing more than 500 people.

- The UK is the ninth largest manufacturing country in the world, exporting £275bn of goods in 2019.

- Manufacturing contributes one-quarter of the nation’s GDP each year.

- The growth of manufacturing SMEs is continuing, with a 6 per cent increase since 2010.

The societal and economic value of SME manufacturing businesses, therefore, is indisputable. SMEs also contribute significantly to local economies by providing secure, well-paid jobs; injecting much-needed investment into community projects, particularly those which previously would have qualified for European Union support; and strengthening the fortunes of other SMEs who work collaboratively in a manufacturing ecosystem.

SMEs: The Invisible Manufacturing Experts

It’s fair to say that the culture in which SMEs operate makes it challenging for their voice to be heard. Emerging from humble roots, often built up by families over generations, owners of manufacturing SMEs often shy away from shouting out about their achievements: achievements which often go unnoticed by the general public and politicians alike. During the Covid-19 lockdowns, many SMEs pressed on, continuing to produce and distribute the vital supplies upon which the country relied, while more visible public bodies, like the NHS, (rightly) received public commendation.

Equally, a lack of Government support has resulted in a lack of awareness among the British public of the important work of manufacturing SMEs. In contrast, German engineers are as highly regarded as doctors, a situation that should be reflected in the UK. Many young people are unaware of the positive aspects of a career in manufacturing, including high pay and job security, instead perceiving engineering to be dreary and unpleasant.

Engineering Change