Hone-All Precision Ltd

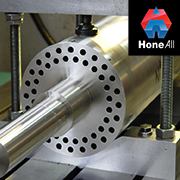

Our deep hole drilling service prides itself on being able to produce accurate, concentric bores time after time. We have the mechanical ability to perform deep hole drilling on all materials and can machine shape bars, blocks, castings and finished components.

Often referred to as gundrilling, at Hone-All, we use of deep hole drilling services to create precision, circular bores to gain close tolerances.

-

HOW TO AVOID DRILL WANDER WHEN GUNDRILLING OR DEEP HOLE BORING

26 March 2019A deep hole is defined by the depth-to-diameter ratio and every hole larger than a ratio of 10:1 is considered deep. There are lots of applications for deep hole drilling across many industries, with the origins tracing back to gun barrels. Deep hole drilling is used in different materials and can help achieve a tight diameter, straightness, and a perfect surface finish.

Deep hole drilling is done on special deep hole drilling machines, which are assembled to ensure efficiency, straightness, and precise drilling. Modern technology allows for gundrilling of small diameter holes over long lengths.

However, drilling a straight hole and exactly where you need it isn't always easy. A drill can be difficult to control while maintaining accuracy, especially when particularly deep holes are required. Luckily, there are proven techniques and reliable equipment now available to ensure engineers achieve a precise result.

Find The Centre And Drill On Target

Position is everything – on or off centre, accuracy at the start improves the quality of the entire process.

To assist, there are centring tools and fixtures that can help when setting the machine. Self-centring bits help centre the bit in the machined hole by guiding the tool to the correct location but it can be as easy as simply marking with a cross!

Contra-Rotation

After ensuring the most accurate start point for drilling, the most accurate way of minimising drill wander is to contra-rotate the component. This means that the part will be rotating one way when held in the chuck and the gundrilling tool will be rotated in the opposite direction ensuring that the opposing forces come together to create a bore as straight as possible. In some cases, i.e. in block or PCD work, this is not always possible and therefore the standard industry parameters for deep hole drilling will always be quoted. These are 1mm of wander for every 1 metre drilling or 0.001” per 1” drilled. This means that if set correctly, your start hole will be perfectly accurate, the hole will be dead straight but the exit point will be at worst, 1mm off centre in a 1 metre long component. Gundrilling cannot create a bent hole, this is a common misconception. However, the hole can wander off centre from the original start line.

Clear The Swarf Often

How the swarf chips and the effectiveness of its removal can also cause a drill to wander, which can result in oversized holes or even broken drills. The tips and / or the swarf can get trapped in the bore or twisted around the drill and you will have to spend lots of time clearing it. To avoid this, an engineer should watch the swarf carefully and based on its characteristics, adjust the feeds and speeds to improve the chipping effect.

The Hardening Effect When Drilling Stainless Steel

When drilling certain steels, the work hardening effect can also cause problems. This is when the steel slowly hardens as it is cold worked, causing the drill to wander or even cause excessive wear on the tip resulting in the creation of an oversize bore.

During deep drilling, it's vital to maintain the feed to easily cut through the steel's hardened layer. If you have to re-enter the hole after backing out, always do it at a full feed rate and speed. However, if you need to make sure the feed rate is maintained, reduce the tool speed.

Deep Hole Boring & Drilling Experts

Deep hole boring takes a precise approach to ensure you get the result you need, first time. Its worthwhile shopping around for an expert business – such as our Hone All team – with extensive experience of deep hole drilling for a range of clients in different sectors. For a free quote, please don’t hesitate to get in touch by phone on 0845 5555 111.

-

HOW TO ACHIEVE WALL THICKNESS CONSISTENCY WHEN GUNDRILLING

26 March 2019Gundrilling refers to a process of drilling deep, precise holes in many different materials, from super alloys to aluminium. The key elements to deep hole drilling methods are tight diameter control, good finish, and straightness.

Deep hole drilling is used across many industries and for a variety of applications, such as armaments, oil and gas exploration equipment, engines, and aerospace equipment being the most common applications for deep hole drilling. In every industry, accurate bore quality is necessary for the proper performance of the end product, for example, a landing gear should easily retract. That's why deep hole drilling should be accurate, time-efficient, and reliable. Wall thickness is one of the indicators of quality and its consistency is vital.

Understanding Uncertainty

One of the key things you should know about gundrilling is that it can be quite unpredictable. For example, no handbook will tell you the optimal speed or feed rate as materials differ in characteristics even when of an expected standard and drill tip wear or oil pressure can impact the effectiveness of the speeds and feeds selected. Instead, the way to choose the right parameters for different materials is for an experienced operator to use conservative parameters and then slowly increase them to the extent the material permits.

In addition, it can be hard to predict the position of the hole. The fact is, even a shallow hole right in the centre can have a measurable amount of straightness error and the length of a gundrill can exaggerate the error. For example, if you have a drill with an L:D ratio of 50, you might have an exit point landing anywhere within an area several times larger than the size of the cross-sectional area of the drill.

Another underappreciated factor is the difficulty that different materials can present. For example, softer materials can be hard to drill because chips will clog the oil feed hole. Hard materials are challenging as well due to tip or tool wear. In this case, only years of training and experience will help you achieve minimal drill wander and wall thickness consistency.

Special Equipment To Measure Wall Thickness

You can drill a hole and machine the outside for a consistent wall thickness. If the drill wanders, it will cause wall thickness inconsistency between the two ends. It's important to monitor the position of the drilled hole using special equipment to effectively measure the wander and then implement the required measure to correct it.

On through bores, this simply involes turning the billet between centres and removing the material from the relevant ends to bring the bar back to true.

On blind bores, the best method is to use a special ultrasonic device to measure the wall thickness by placing an ultrasonic device at different spots around shaft. Measurements with these devices are accurate and you will be sure to identify the end point of the gundrilled hole. These measurements are then used to off-set the billet when set on a lathe the error is turned off the outside diameter leaving the bore to outside diameter tolerance back within microns.

This is one of the reasons we always recommend that the customer starts with oversize material and machines all further detail from the bore produced or indeed, asks us to do this for them. This guarantees a clean up situation and that the billet will be suitable for any and all future applications.

More Information

The only certain way to ensure wall thickness consistency is to get professionals to do the job. Contact our team at Hone-All Precision today to get a free quote. You should also take a look at our free ebooks, which examine different aspects of CNC machining, drilling and honing from a buyer’s perspective.

Click here to download The Guide To Deep Hole Drilling, Boring & Honing

-

AS9100 REV D HELP!

26 March 2019The new revision of AS9100 was published in 2016 but it has been reported that many businesses have delayed getting the transition progressed. Accreditation Bodies are reporting that as few as 40% of their client base have gone through the transition and many are planning an initial transition assessment in March 2018. The fear is that there will not be enough time to rectify NCRs raised before the September deadline. Many are reporting that the assessor resource will also be stretched beyond capacity, leaving many clients without any Quality Accreditation in October 2018.

The new 9100 format is in line with the Annex SL structure common to ISO 9001:2015, ISO14001:2015 and all the new standards going to revision. This is a plus for those organisations with multiple accreditations but all have to go through the initial pain and resource hungry transition. The shift in approach is quite rightly asking leaders to consider their QMS as part of their strategic planning process and an integral part of all the business decisions. This is not an easy step for every company.

‘Leadership and Commitment’ (Clause 5.1) is put to the test, ‘Resources’ (Clause 7.1) are stretched and ultimately a business has to consider the ‘Risks and Opportunities’ (Clause 6.1) associated with keeping or dropping formal accreditation.

At Hone-All Precision we took the decision that the AS9100 accreditation is vital to our business. Its structured approach allows us to control, monitor and improve our performance and is key to meeting our customer requirements and our own goals for business excellence. The formal accreditation is a demonstration to our Interested Parties of our commitment to providing a quality product and service.

With the decision made we had to formulate a plan to progress through the transition, within the timescales defined by UKAS, but allowing us to continue ‘Business as Usual’. We took a step back and asked some searching questions of ourselves and came to an honest decision to go and find some help. There is no dishonour in this decision and we have benefitted from an outsider’s view of what we have been doing with our processes for many years.

MLP Management Systems Limited have been working with us to develop a system that meets the requirements of AS9100 rev D but is still our QMS. It does not sit on the wall gathering dust but is the heart of what we do. Mel Bray has brought her 27 years of experience of management systems and refreshed our system to meet the new standard and our ongoing business needs. By engaging with our staff we have refocused their attention and gained their support for the improving objectives of the Business.

-

THE BLACK ART OF HONING

26 March 2019Honing is one of those subcontract services which often suffers an unfairly bad reputation!

Covered in the apprenticeships of old, it's always the honing machines that bring either the wry smile or comical grimace when people visit as if they were lucky enough to go through a full apprenticeship it was either one of their favourites or the hated machine that just “had to be used to pass the exam”.

There are a number of reasons why honing suffers and these vary greatly including:-

- Cost - customers can often feel it's an expensive process simply because they are requesting honing when they haven’t been able to achieve the specified bore tolerance through machining and didn’t allow for any honing costs so any cost, irrespective of how good value it is, is eating into their margins.

- Delivery - it is often difficult to explain the time frames required to hone out a large amount of stock from a bore. This is not because the honing process is necessarily always slow (although some bores and tolerances do require extremely careful handling) but often it’s for the simple reason that when very large amounts of stock need to be removed, the process needs to be carried out in a number of stages in order to let the material cool and normalise before commencing the operation again. This will increase cycle times which in turn will increase the price leading to further claims that the process can seem expensive at times. To overcome large amounts of material left in the bores, we can offer to single point bore depending on the size and length of the parts. Alternatively, we can offer to skive through the bore of long cylindrical parts up to 3000mm long and then finish hone them. If honing is the only option, this can be done but it may not be very economical and if at all possible we would ask that you call us prior to machining so that we can advise on a stock removal level which would be appropriate for that particular component. This not only reduces the cost for the customer but also reduces lead time. As a result, they will win more work, be more successful and we all experience a positive impact.

- Quality - sometimes, the teams within the quality departments we work with haven’t seen or experienced honing and therefore they are not aware of exactly what honing can and can’t achieve.

So What Is Honing & What Can It Do For You?

Internal honing is the removal of material from a round bore using tools with abrasive stones which expand under pressure to cut and is used for the following purposes:-

- To achieve tighter tolerances than can be achieved with conventional machining methods or tooling.

- To improve Surface Finish to ensure smooth fits with mating parts or reduce wear or in some cases, to roughen a surface finish depending on the application i.e. creating cross hatch finishes for oil retention.

- To alter the size of the bore when design changes have been made or requested.

Factors that can affect the quality of a honed bore are:-

- Temperature - hence the requirement to allow the component to normalise @20°c.

- Parallelism & Roundness from prior machining.

- Gauging selected and accuracy of the setting and measurement.

Gauging is sometimes a difficult factor as smaller batch quantities do not always justify or allow the expense of the perfect gauging and customers may have to make do with what they have. For example, some components require air gauging but this can cost £400-£500 and therefore the customer cannot supply this for an order of £100.

Obviously, here at Hone-All, we have built a large stock and variety of gauging over the years but it’s almost impossible to cover every size due to the small increments the gauges are sold in!

Blind Bores

Blind bores are another reason for honing getting an unfair reputation at times. Despite most honing specialists making the limitations of honing tooling quite clear to customers on their quotations and stating that the tool cannot reach the full depth of the bore, this information is often not picked up by the customer on the quote and therefore they can sometimes feel that we have not completed the part to drawing.

Components with tight tolerance or high surface finish blind bores could be designed with a relief in the bottom of the bore. The length / depth of the relief is relative to the bore size but as a general guide, 5mm relief on a 50mm bore, 10mm on a 100mm bore would be sensible (and highly desired!) to prevent this occurrence.

What Honing Cannot Do!

Another reason we honing companies may suffer can be due to a lack of knowledge by the customer of the honing process. One customer of ours had raised over 30 NCR’s against us (without forwarding them so we were unaware) simply because the parts did not meet the concentricity limits.

If we had machined the parts, we would accept the NCR’s, investigate and find the cause. However, we were only honing the parts and the one thing honing cannot affect is the concentricity of the bore to the outside diameter. We can only follow the existing bore and if required, this would need to be cylindrically or jig ground to correct.

And the final factor which may impact quality is indeed, the operator. However, with over 40 years of experience within this field, our engineers are highly skilled and fully trained and that’s why we would always recommend speaking to our honing specialists to discuss your requirements at the earliest possible stage.

That’s why we have written this guide.

We hope that the information within it will not only educate and raise awareness of the black art of honingbut also enable our customers to understand the time frames, the skill, the requirements and limitations of the honing process.

About Hone All

At Hone All Precision we are a family run engineering firm with extensive experience serving clients in the petrochemical, medical, packaging, printing, aerospace, motorsport, hydraulics and automotive manufacturing sectors. Our full range of services are carried out in-house at our Leighton Buzzard (UK) workshop by a team of experienced, qualified CNC engineers. If you’d like to chat with one of our engineers about a project you’re working on, or request a bespoke quote, please call us on

0845 5555 111

or

01525 370666

Feel free to contact us and speak with an expert even if it is before you’ve commenced the design process as we are happy and willing to pass on our experience and knowledge to save time, money, frustration and benefit not just our customers but our competitors too.

-

X-FACTOR VS FEAR FACTOR: ARE YOU STILL GETTING REAL VALUE FROM TRADE SHOWS?

26 March 2019We love attending trade shows. They are a fantastic opportunity to keep up-to-date with industry trends, meet suppliers and forge links with customers old and new. Sometimes attending a dynamic trade show or exhibition can give your business the X factor – that stimulus to growth that turns your year around and opens up exciting new opportunities.

But the opposite can also be true. We’ve probably all had the experience of attending a trade show with high hopes only to come away disappointed. Or, worse still, to attend an exhibition with doubtful returns, just because you feel it’s the right thing for you to do. This is where the X-factor becomes the fear factor: fear of missing out on new business, fear that your customers will think you’re no longer trading, fear of your competitors gaining ground on you!

Thinking Of The Returns

Is this fear well placed, or is it okay not to exhibit? Attending a trade show is a big investment in time and money for any business. This is true even as an attendee. For exhibitors, the costs are much higher, so there should always be something to show for your investment at the end. Simply attending in order to allay your fears of what might happen is, in our opinion, a pretty expensive risk aversion strategy.

How Well Attended Are Trade Exhibitions?

Bear with us on this. Let’s have a quick look at attendance stats for the main industry exhibitions and see if there is an alternative:

Advanced Engineering, Birmingham, 31/10-01/11/2017: we couldn’t find solid attendance figures, but according to event organiser EasyFairs, the 2017 show, for engineering businesses in the aerospace and automotive sectors, attracted 15% more advanced bookings than 2016. Early bookings for 2018 are already up 35% on this year.

MACH Exhibition, Birmingham, April 2016: Around 25,000 attendees visited in 2016. The 2016 and 2014 shows sold more commercial space than any other event in the show’s history.

SPE Offshore Europe, Aberdeen, 03/09 – 06/09/2017: This year’s Offshore Europe exhibition, which we attended, announced disappointing attendance figures of 36,000, down from 55,000 in 2015 and over 60,000 in 2013.

However, attendance figures do not necessarily reflect “buyer” figures. Many attendees are there to generate business themselves and are not necessarily attending the show looking for suppliers but their own opportunities. For example; the recent explosion in recruitment agencies account for a great number of attendees alongside those who choose to no longer exhibit and so “walk the floor” as it’s often described. Breakdowns of companies and job function are rarely audited or published and so this again raises the question of how many actual opportunities are available from the thousands of attendees listed.

What Does This Mean?

Businesses are clearly still going to trade shows, with figures that increase year-on-year in some cases. A survey of MACH attendees in 2017 showed that 90% of exhibitors generated new leads and 76% reported improved relationships with their clients as a result. However, this must be balanced alongside the issue that most companies do not want to admit that a show did not work well for them and good news stories following a show can often guarantee editorial within supporting trade publicity channels.

What you get out of a trade show may also depend on your industry. The comparatively low attendance of the oil and gas tradeshow Offshore Europe reflects a difficult time being had by many businesses in the industry due to low oil prices, whereas the aerospace and automotive sectors are thriving.

Alternative Ways To Generate Leads

No matter how successful an exhibition, attendance figures are always fairly low when compared to the market as a whole.

Should engineering and manufacturing firms be concentrating more on digital marketing to expand their customer base and develop client relationships? We believe that yes, they should. We still plan on attending important trade shows, but have chosen to no longer exhibit within them unless we are attending as part of a group of companies exhibiting and selling a complete manufacture & supply service or as an associate member of our trade organisations.

We refuse to let the fear factor dictate our investment decisions and are confident that our customers and suppliers will know we are still active in our market place through our constant communications and updates and continued excellent service provision.

We believe our time and investment is better spent developing and expanding upon our existing relationships and utilising other marketing opportunities which has begun to bear fruit in new leads and clients at a faster and greater rate than any other exhibitions or channels we have used previously.

For businesses who are demoralised by their experience at trade shows or simply want to diversify their lead generation strategy, the internet offers very real opportunities for expansion. This is a topic we are always very happy to discuss, whether by telephone, here at Hone-All, over coffee at a trade show or by message through our Linkedin accounts.

-

HAVE YOU EVER PAID OVER THE ODDS FOR DRILLING, BORING OR HONING?

26 March 2019If so, you’re certainly not alone.

Drilling, honing and boring costs are notorious for being something of an arcane secret for people who aren’t ‘in the know’ about the process involved. We have attempted to shed some light on the world of pricing in our latest downloadable e-book: The Guide To Deep Hole Drilling, Boring & Honing Costs. You can download a copy by clicking here.

With a focus on tubular component manufacture, but also dealing with CNC machining more generally, we explain the different factors that contribute to the quotes you receive, and why in some circumstances the final bill may be more than you originally expected. If you seek out five quotes for deep hole drilling, boring & honing, the likelihood is you will receive five wildly different figures. Why is that, when the process and technologies used are very similar?

Pricing Variables

The reason is the number of variables involved in pricing, and this is an area where, unfortunately, some companies are less than transparent.

There are some solid reasons for differences in price, of course. These include the complexity of the component, the materials used and the order volume – standard factors. Compliance is also a factor. For instance, parts used in the aerospace manufacturing industry have to comply with EN 9100 procedures for all components, whereas this is not obligatory for other sectors. This can affect price due to the administration and inspection requirements but can at times enormously increase the quality and reliability of the final product.

The Problems With Standard Quoting

Other factors are not so easy to predict at the quoting stage, which is why standard quoting is not always the best approach for deep hole drilling, boring or honing services. It is natural for businesses to want to standardise their quoting mechanism. Many quotes you request will be quickly generated on a standard spreadsheet. However, this rarely takes into account the issue of drill wander, which can be accounted for but never avoided entirely. When you have ended up paying more than you had initially thought for your job, chances are it is due to unforeseen expenses occurring from drill wander. You may have also experienced delays with that job for the same reason.

For a standard quote to work accurately, it also assumes that your technical drawings are pinpoint accurate. Unfortunately, this is not always the case. Incomplete or inaccurate technical drawings will adversely affect the accuracy and suitability of the final product, adding cost and time to your work.

Bespoke Quotes

These are the reasons we do not have a standard quoting policy. Every quote is bespoke. We like to sit down with you, or chat through your requirements on the phone, and will never issue a comprehensive quote until we are sure your technical drawings match your required outcome. This is something we can help you with. We have decades of experience working with industrial components of all varieties, and can help get your technical specs up to speed, so you can use them again and again without issue for many years to come, whether with us or an alternative supplier.

By closely examining the technical specs and carrying out a contract review process on the enquiries we receive, we are better placed to predict and compensate for those variables that always occur during the machining process itself – drill wander being the most obvious example.

Transparent, Accurate Pricing

So if you have been frustrated with pricing, please do have a look through our e-book. It explains the quoting and pricing mechanisms of our industry in clear detail, and gives you the information you need to expect and receive accurate pricing on all your quotes. We have a unique way of working with our customers here at Hone All, based on your specific performance requirements, budget and timeframe. To find out more, please give one of our team a call. The number is 0845 5555 111.

You can also request a call back at a time of your convenience by using our contact form or e-mailing us at sales@hone-all.co.uk

-

COMMON MISTAKES TO AVOID WHEN GUNDRILLING

26 March 2019Gundrilling (alternatively called Deep Hole Drilling) is a reliable method used to make precision holes in a wide range of metal and plastic components. The method is known for its efficiency in creating perfectly round drilled holes and straight drill channels. However, sometimes mistakes are made with gundrilling that affects the final accuracy of the result.

These are the most common ones to be aware of:

1) Using The Wrong Nose Grind Geometry

Standard gundrill tips utilise an N8 nose grind, with an R1 relief. These have an inner angle of 20°, with a 25° dub off and a 30° outer angle. Nose grind is important because it affects how swarf chips are formed, the finish of the drilled hole and coolant flow. Using the wrong nose grind may result in pressure build up, erratic flow rate and an unsatisfactory finish. N8 nose grinds are great for some materials – such as nickel alloys or stainless steel, but can be problematic when working with brass or aluminium. With these metals you should try an N4 nose grind with an R4 relief. These have the same inner angle and dub off of the N8, but have a shallower outer angle of only 15°.

2) Tip Selection

Drill tips can have one or two holes depending on the diameter of the gundrill and come in a variety of materials and forms. Choosing the wrong tip or drill grind for your application can lead quality issues and / or a build-up of swarf in the bore causing blockages and excess pressure.

3) Guide Hole

If no dedicated gundrilling machine is available, you can use a CNC lathe to carry out the operation, but the speed bit system requires you to drill a start hole first to ensure the gundrill has an accurate starting point. This needs to be at just the right depth, tightness and straightness – within the tolerances of the gundrill diameter. However, getting the start hole wrong will cause you issues. Be conservative when planning your start hole parameters. Defining the specs too tightly may give you insufficient room to manoeuvre when making the main cut, especially when using small drill bits.

4) How Much Pressure?

Your goal should be a steady coolant stream, not a rush or dribble! The smaller your drill bits, the higher psi you will need to apply to achieve this. A very common mistake is not applying the correct pressure. Too much and you risk damage to the drill. Too little and you compromise the quality of your result.

High Quality Gundrilling Solutions From Hone-All Precision

We specialise in a range of gun drilling and other CNC solutions for precision parts used in many different industries. Chat with us about your project requirements and ensure your drilling is carried out quickly and with precision accuracy. You can request a quote online by filling in our online contact form. Alternatively, you can chat one of our team by calling 0845 5555 111

-

HOW TO ACHIEVE A PERFECT RESULT WITH GUNDRILLING

26 March 2019When carried out using the right equipment and with the right training, gundrilling delivers reliable results each time. This is the reason the technique – which you may also know as deep hole drilling – is so widely used in manufacturing. Hundreds of aerospace, automotive and medical components, among others, use gun drilling to produce precision holes of almost any length.

Gundrilling is a precise science that can be tightly controlled to deliver results within very tight parameters, but there are still several factors to take into consideration. A precise result is achieved by controlling four variables, which we will look at below:

1) Fluid Volume/Flow Rate

How much coolant do you need to achieve your result? Although total volume and flow rate are technically two factors, it makes sense to deal with them together. For each revolution of your drill, you will need enough coolant to completely fill the drill hole. To determine this you need to know:

- The speed of your drill bit in rpm

- The diameter of the gun drill

- The depth of the drill hole

Volume (V) and flow rate in gallons per minute (GPM) can be calculated using two simple equations:

V= (0.785x diameter2 x depth) / 231

GPM = V x RPM of drill

Doing these in order will give you a rough figure for your flow rate, e.g. 0.5 GPM. However, in practice your flow rate will always be less due to losses from friction. It is therefore important to control the pressure of your drill.

2) Pressure

Gundrilling CNC operations are high-pressure systems. Maintaining stable pressure in psi is important to retain the correct flow rate. However, blockages can occur, resulting in a build-up of pressure, which can jeopardise the safety of the machine and operators. It’s therefore important to have efficient pump sensors that can moderate the flow of coolant and avoid pressure build up. Clearing a blockage always requires more coolant volume to flush away the obstruction, but this can risk increasing pressure still further at a critical point. The answer is to have a surplus of coolant volume available on top of that which was calculated by your base equations.

3) Feed Rate

Drill feed rate affects how easily the drill cuts into the material, and how efficiently it removes swarf from the cutting zone. Your feed rate will also affect the size of the chips themselves. Higher feed rates often create a proportionately higher work hardening rate. This creates smaller chips that are easier to disperse.

Find Out More

Gundrilling is one of a number of CNC services we offer here at Hone All Precision along with Deep Hole Boring, CNC Turning and CNC Honing up to 3 metres long.

Confused as to which service you need for your application? Get in touch with one of our team for an informal chat today. Contact us at sales@hone-all.co.uk or call us on

0845 5555 111 / 01525 370666.

-

WHAT IS GUNDRILLING & WHY YOU NEED IT!

26 March 2019The process of gundrilling was initially developed to create uniform sized holes in artillery pieces and rifles. Techniques and technologies were set in place to give repeatable, highly accurate results on mass armament production lines, from the late 19th century onwards. Gundrilling is still used in the defence industry, but has far wider applications too.

You may have heard of gundrilling under its less militaristic name Deep hole drilling, which is how we refer to the process on our website. In fact, the old name is virtually all that remains of the technique. Deep hole drilling has evolved enormously, especially over the last few decades. Industries who use gun drilling now include aerospace manufacturing, medical technology, motorsport, hydraulic systems, the oil and gas sector and many more besides. It is the most accurate and dependable way of drilling holes up to 30mm diameter of any depth and length in a wide range of substrates. Gundrilling will work on components made from titanium, wood, aluminium, stainless steel, thermoplastic and many other industrial materials.

What Is Gundrilling?

Is there a definition that we can use to distinguish deep hole drilling from other types of conventional drilling? In general, conventional drilling is fairly limited and can only achieve a ratio of 10:1 length to bore whereas deep hole drilling offers the huge flexibility of an increased ratio in excess of 100:1. There are hundreds of different gun drilling machine designs and techniques, all developed to deal with a specific type of component and the needs of various industries.

They all have certain features in common:

- The gundrill tool is a toughened tube, swaged into a kidney shaped profile with a tungsten carbide, kidney shaped tip. The tip will then have one or two coolant holes dependant on the diameter of the drill tip.

- The outer edge of the gundrill tip makes the initial cut which then loads the bearing pads, forcing them into the wall of the bore creating a burnished, and sometimes, a mirror finish.

- The gundrilling oil is fed through the tool and tip at high pressure to lubricate and cool the cutting action and in addition, expels and removes the swarf generated from the cutting action.

Why Use Gundrilling?

Let’s take a look at the advantages of gun drilling over other CNC techniques. Why use this method as opposed to any other?

- Gun drilling creates precise, accurate holes, using only a single pass.

- It is ideal for sustaining precisely round holes and exactly straight drilled channels.

- The guide pads and clearance faces of the drill reduce or eliminate the need for secondary finishing.

- The drill channel is kept burr free.

- Drilling can be carried out within high tolerance parameters to exact specifications.

- Gun drilling is faster and more cost-effective than other methods.

Gun Drilling/Deep Hole Drilling Services From Hone-All

At Hone-All we provide a wide range of drilling, boring and honing services to clients in many different sectors, including Oil & Gas, Hydraulics, Medical Technology and Aerospace Manufacturing. For full details or to request a quote, please get in touch by calling

0845 5555 111 or e-mailing us at sales@hone-all.co.uk.

-

INTRODUCING OUR LATEST COLCHESTER CNC LATHE

26 March 2019We have recently been enjoying utilising our latest Colchester CNC lathe – the newest addition to our CNC large turning section here at Hone All Precision. The Colchester Lathe Company, based in Heckmondwike in West Yorkshire, is one of the world’s leading producers of CNC lathes and supporting equipment.

Supplied by R K International, whose exceptional support and service is invaluable to us here, the additional machine has increased our capacity to help deal with the increase in orders due to the upturn in the Oil & Gas sector.

Our new acquisition is a 2m flatbed lathe from the Colchester Centre Lathe series. We selected it for its ease-of-use, simplistic programming and efficiency, and the opportunities it offers for a range of specialist modular upgrades. For performance and accuracy, Colchester lathes are hard to match. Our new lathe is also one of the fastest machines we have had the pleasure to work with, increasing our work capacity and allowing us to reduce lead times on many client projects.

Key Features Of The 6000/120 Centre Lathe Include:

- Swing over bed - 800mm

- Swing in gap - 870mm

- Swing over cross slide - 520mm

- Distance between centres - 2000mm

- X axis cross slide travel - 400mm

- Spindle centre height from bed - 395mm

- Spindle centre height from floor - 1200mm

- Spindle nose (Camlock) - D1-11

- Spindle bore - 120mm

- Spindle front bearing inner diameter - 156mm

- Spindle motor - 22/26kW

- Spindle speeds (programmable) - 15-1500rpm

- X /Z axis rapid traverse rate guards open - 3000/4000mm/min

- X/ Z axis rapid traverse rate guards closed - 3000/10000mm/min

- X axis ballscrew, diameter x pitch - 25 x 5mm

- Z axis ballscrew, diameter x pitch - 50 x 10mm

- Tailstock quill taper - No. 6 MT

- Tailstock quill diameter and travel - 120/210mm

- Cross slide width - 280mm

- Bedway width - 550mm

- Turning tool section - 32 x 32mm

- Approximate nett weight - 6000kg

CNC Honing, Deep Hole Boring & Drilling Services From Hone All

At Hone All Precision we offer a wide range of CNC machining services to clients across the UK. We use the latest inspection and turning technology to achieve long lasting and repeatable results with every project. Our latest investment is part of our ongoing commitment to provide the highest standards of customer service and product delivery in the wide variety of sectors we currently serve. To find out more, please get in touch by phone on 0845 5555 111

-

WATCH HONE ALL ON MTD CNC'S #SWARFANDCHIPS

26 March 2019Watch our appearance on #SwarfandChips, the weekly engineering YouTube show from MTD CNC. You can watch the video on MTD CNC's website, YouTube.

-

A PERFECTLY FORMED BOTTOM – DOES YOUR BORE REALLY NEED A FLAT BOTTOM?

26 March 2019Producing blind bores into precision machined components, and responsibly quoting for them, should always result in more questions for the customer. As much as time is short during our busy working days, and these queries often result in a little lost time, it’s always worth investigating at the design stage whether the form required suits the process needed to produce it or will require a non-standard tool.

Designers are often quick to add a “shoulder” type form at the bottom of the bore, referred to as a “flat bottom” but there is rarely a true requirement for this and the consequences can impact the competitiveness of the quotation both in terms of cost and lead time.

Deep hole drilling and deep hole boring to a depth creates what is referred to as a “w form” as standard. In some cases, another bore will be breaking through into the initial blind bore causing most of the w form to be lost and leaving a step either side. However, when there is a single-blind bore, it is unusual for the w form to really make a positive impact to the design unless a mating part or seal is going within the bore which needs to fit or hit onto a straight surface. There are of course legitimate reasons for the requirement of specially formed bores, sometimes for strength or lightness, and other applications we’ve mentioned, but it is worth noting that most forms can be produced but at a detrimental effect to the cost and lead time.

-

THE TREPANNING TOOL – A MODERN MANUFACTURING MONEYSAVER

26 March 2019This is a part that has been trepanned.

“I thought a trepanning tool was an unpleasant medical device from the 19th century! I didn’t know it was also a manufacturing process!”

When Jo asked if she could feature Hone-All Precision, our director, Andrea Rodney, suggested that the focus of the feature should be Trepanning.

Jo only knew this word as a form of surgery in which a hole is bored into the skull. However, there is another, less well-known, industrial application for drilling large deep holes in metal parts whilst still retrieving a valuable core.

It can be used in many industries, including Oil & Gas and Aerospace, where bores may be required in components or if there is insufficient horsepower to drive solid drilling tools.

This application is also recommended if there is a through bore or long design, which makes it ideal for specialists in deep hole drilling, honing and turning up to 3 metres long - like Hone-All.

Sometimes the trepanned hole is fit for use as bored but often it is meant to be a roughing operation to be machined to a closer tolerance or honed through for a good surface finish and improved geometry.

So, What Does A Trepanning Tool Do?

Andrea explained that this form of cutting machine has two uses:

1. It can remove a solid core from a piece of round bar or material. For example, a customer has a 300mm diameter bar but the design requires a 200mm hole up the middle of it. The tool can trepan that material out and give them back the solid core, rather than chippings or swarf. This means that the slug can be used to make another component instead of becoming waste.

Say you had a pre-op 200mm bore out but tight tolerance means that the company cannot get up to that size, a trepanning device would be used to do a rough cut to remove the majority of the material in the most effective manner.

2. Alternatively, imagine a bar with a big flange on the end. So, you have a 400mm diameter bar but most of it needs to be turned down to 200mm. You could use the trepanning tool to part off the outer sleeve.

It would take numerous passes to remove 200mm from the outside diameter of a bar. So, rather than turning for hours and removing a huge amount of material as swarf, it is possible to use one machine process to produce a solid sleeve that can be used again.

-

HONE-ALL ASSISTS LOCAL COLLEGE TO OFFER SKILLS TARGETED APPRENTICESHIPS

26 March 2019Central Bedfordshire College provide excellent learning and progression for our communities in Bedfordshire and beyond. Their new state-of-the-art Engineering and Construction Skills Centre in Leighton Buzzard and team of industry professional teaching staff are on hand to deliver the most up to date and comprehensive skills training to ensure your future in these exciting sectors.

Central Bedfordshire College is the only college in the area to be awarded a Grade 2 by Ofsted twice in a row. The most recent inspection in March 2016 highlighted the college’s strength of engagement with local employers and the important role it plays in meeting social and economic needs in the area; it also commented on the standard of practical skills gained by students improving their overall employability and the clear career pathways in place which result in 98% of students successfully progressing to university or straight into employment.

This exciting new facility in Leighton Buzzard has been created through essential collaboration with key industry partners and employers including Central Bedfordshire Council, SEMLEP, Hone-All Precision Ltd., BE Aerospace, Grundfos, Calex Engineering, BCS and Auto Technology. The partners in the development and build of this new facility have provided substantial guidance ensuring that the college has the right equipment and facilities to help learners develop the skills employers are searching for.

The Leighton Buzzard Engineering and Construction Skills Centre has a range of learning spaces including a fully equipped Electronics Workshop, CAD/CAM Classroom, and study spaces where students will study Maths, English and Employability as well as their main chosen subjects in Engineering or Construction.

The Leighton Buzzard campus also has a fully fitted CNC Machine Workshop that comprises of 2 x 4-Axis CNC Mills, 2 x Multi-tool CNC Lathes, 1 x Coordinate Measuring Machine (CMM) and industrial 3D Printer technology to ensure that students are learning the cutting edge skills that the sector demands whilst giving them the opportunity to understand future technology.

-

NOT YOUR AVERAGE GUN DRILLING OR BORING MACHINE SHOP

26 March 2019You may think that they all say that, and they probably do.

Therefore, it’s worth taking two or three minutes to understand our justification for claiming that you will not find better – or at least understand our approach and the way we do business. It’s the only way for us, and it has delighted thousands of customers throughout the years. We believe we have the winning formula of professionalism, advanced technology and industry expertise and it’s all at your disposal.

How Confusion Easily Creeps In To A Quote

The technical complexity of the specialist services available at Hone-All, including deep hole boring, deep hole drilling and honing, are unsurprisingly something of a mystery to some people. That’s perfectly understandable unless you have worked within a specialist machine shop and put in the hours learning about and perfecting these techniques.

This sometimes makes it difficult for customers who want to utilise these services. The variations of the different levels of machining available can dramatically impact the costs quoted at the initial stage but understanding the implications of those differences is not always intuitive from a brochure or website. There can be a whole host of factors that may at first appear to be just complications and cause for confusion. They can lead to a cost V quality conflict from simply specifying the level of machining, the technical specification and the overall impact on the finished component.

That is why we never just key some numbers into a spreadsheet and take the first answer it pops up.

Every Single Job Deserves Thorough Investigation

Issuing quotes on request is simply a cost of doing business but it’s a considerable cost to us. This is because genuine lasting quality starts with a true and perfect understanding of the requirement. We study drawings and almost always follow up with a series of questions. Our desire to gain clarity and certainty is your guarantee that you will get what you want – not just from us but from the whole process and resulting product.

We have often seen quotes being returned quicker and at a cheaper rate than ours. If we are able to speak to the customer and explain why our costings may be a little higher than our competitors, in most cases it is because we have included additional operations after considering the overall finished quality of the component and how the results of our machining will impact our customers machining further down the production sequence.

We appreciate that for some people the cost is everything and the only consideration. We don’t go along with that because going with the lowest initial cost can come back to bite one all too often.

Aerospace Industry Standards EN 9100 For Your Benefit

Regardless of your industry sector, all our procedures and order processing adhere to this superior standard. Not all suppliers apply this strict Aerospace Industry standard to all their orders unless it is specifically required, whereas we follow EN 9100 procedures for all components irrespective of sector or specification. This effectively eliminates the risk of product defects causing you problems down the line.

A Case In Point

For deep hole boring on bores from 20mm – 200mm+ diameter, a standard industry tolerance quoted would be ± 0,25mm. Therefore, any tolerances lower than these parameters will most likely result in a need for honing. However, adding honing to the cost of the sub-contract machining can often result in our quotation not being as cost-effective as the prices offered elsewhere. The choice here is, do we simply quote our standard tolerance and guarantee to win the work with the lowest price, or do we quote on a basis that will ensure the quality the customer really requires? If the tolerance isn’t achieved, the first approach avoids an unwelcome surprise additional cost or delay to the promised lead time when we are half way through the order. The same applies to surface finishes.

At Hone-All, we always choose to err on the side of caution as quality must be paramount and the costs and lead time known in full at the start of the project.

Quality Or Price: Do You Have To Choose?

Quality versus price does not have to be a compromise. At Hone-All we find that the solution comes through honest and open communication. We are transparent about our work and will be upfront about your likely project costs. This being said, our goal is to help you achieve the maximum possible value within your budget. So, based on an assessment of your needs, we will suggest solutions that come in at the lowest achievable cost, bearing in mind your quality requirements and delivery schedule.

-

BRIEF GUIDE TO TREPANNING

26 March 2019Trepanning is basically deep hole boring with a difference in that it leaves a core. It is an efficient method for drilling deep large deep holes that is more cost-effective than deep hole boring.

The most common use for trepanning is cutting a core out of a larger solid leaving two pieces. The removed material is not reduced to swarf as with drilling but remains a solid billet. The most common example is a solid billet that is left with a hole bored through from end to end and a second smaller round bar that is excised by cutting around it. It can be intended as a roughing operation, destined to be machined further or honed to a finer finish. Alternatively, trepanning alone is sometimes adequate for the job in hand. In fact, people often ask for trepanning when all they want is a deep hole or process bore.

Trepanning can also be used on surfaces such as on solid rods or cylinders, or sheet metal. Instead of drilling all the way through, it can be used to create grooves for O rings or recessed mounting slots.

Advantages Of Trepanning Over Drilling

- Trepanning tools can either remove a solid core or the outer sleeve of a billet in less time than conventional machining methods.

- Trepanning tools require less energy than boring tools because cutting out a cylinder takes less time than drilling as the bulk of the stock is not converted into swarf but left intact.

- Trepanning tools use indexable tooling, which makes them very efficient and productive when processing different jobs in quick succession.

Trepanning is often used for creating large diameter holes, usually deeper than one hundred times the diameter. The rational for choosing trepanning is often one of these:

- A standard boring head is either not economical or available

- The customer specifies the return of a solid core either for maximising scrap values or for re-use. (However, this billet would require recertifying and treating if full traceability is required as the certificate would no longer reflect the description of the material.)

- Bore diameter is greater than 100mm typically

- Expensive metals, such as titanium or super alloys are required

The Cutting Process

The cutting system is like the BTA drilling single tube system, but it requires less energy to power the spindle because trepanning cuts less material as it rotates. The feed is typically ballscrew or rack and pinion. Trepanning tools use carbide indexable tooling heads, which are hollow in the centre with peripheral tips and high-pressure coolant and lubricant. The cutting head is sealed against the end of the workpiece by a pressure head at one end and the chuck at the other.

As cutting progresses, the coolant flow pressure removes the swarf by forcing it into the conveyor and the coolant is recycled through the retaining tank. The head and shaft gradually become supported by the bore until it reaches the end of the billet at which point the core can be removed. Load monitoring is commonly used to alert the operator to potential issues during the operation as the cutting edge is invisible for the duration.

Standards

Trepanning is often the first step in producing a part to customer specification. It may be followed by additional machining such as counter-boring or honing. Our engineers here at Hone-All pride themselves in delivering all orders to aerospace standards irrelevant of use or quality requirement. That means you are guaranteed the finest engineered parts. We invite requests to discuss subcontracting requirements, especially for businesses that prize extreme precision and supreme quality.

- Trepanning tools can either remove a solid core or the outer sleeve of a billet in less time than conventional machining methods.

-

HONE ALL DIRECTOR TO PARTICIPATE AT WOMEN IN MANUFACTURING CONFERENCE

26 March 2019The manufacturing sector in the UK isn’t known for its abundance of female employees. Look around a typical manufacturing business and the clear majority of workers from the ground floor to the boardroom are likely to be men. This is especially the case among company directors. Among the largest FTSE100 manufacturers, according to The Manufacturer magazine, only 23% of senior managers are women, while the number of women as a proportion of employees in the manufacturing sector overall – including small businesses – is even lower, at a paltry 15%.

The Manufacturing Skills Shortage

At the same time our largely male sector is hit by a long-term skills shortage in many trades. The answer seems obvious: get more women involved in the manufacturing sector at all levels. Fortunately the tide seems to be moving in the right direction. There are plenty of opportunities in the manufacturing sector and plenty of women ready to take up the challenge. The issue for the industry is partly one of image; where an all-male, macho atmosphere can be off-putting for women, partly one of awareness as the vibrancy of manufacturing is rarely seen publicly and partly one of opportunity – the industry needs strong advocates to promote the benefits and potential of a manufacturing career to young women.

At Hone All we are doubly lucky in having as a director Andrea Rodney, a highly skilled engineering business owner – and a tireless advocate of greater opportunities for attracting more talent into the industry in the manufacturing industry, irrespective of age or gender.

A Voice For The Future

On 21st June 2018 Andrea we participated in the discussions at the Women in Manufacturing Summit in Liverpool, on a variety of subjects, including solutions to reverse the UK manufacturing skills shortage. The summit is an opportunity for industry role models, entrepreneurs, mentors and senior engineers from across the manufacturing industry to share strategies for greater female involvement in the sector. Along with attracting our youngsters into the industry, this is a conversation our industry badly needs to have, and should discuss career opportunities, vocational training and attractive academic pathways for young women just leaving school and university.

-

MAINTAINING EMAIL SECURITY & BEST PRACTICES

26 March 2019The digital economy has made a lot of things easier, including communication and payments, but these changes have gone hand-in-hand with a heightened risk of fraud from cybercrime. Internet-based fraud can take many forms. As individuals, some of us have no doubt had ‘the phone call’ from our bank questioning our recent shopping spree in South Korea. Fortunately, personal losses are usually reimbursed quickly through the bank’s insurance scheme. Risks to businesses are more profound. Companies run the hazard not only of financial loss but also loss of reputation, which can be catastrophic.

HSBC and other banks have all issued warnings to their customers not to open scam emails masquerading as coming from an official source. Unfortunately, it isn’t only banks who are susceptible to such deception.

Some of our own customers have been the victim of attempted fraud through emails purporting to come from suppliers or clients. These frequently come from a trusted email address and contain subjects such as ‘purchase order’. We were recently caught out ourselves by a so-called phishing email. Thankfully it only ended up costing us £500 but it took six weeks and a multitude of e-mails and calls to get the rest of our money back.

To avoid the risk of clients being defrauded, should our email address be misappropriated, we have introduced the policy never to request money by email unless an official statement from Hone All is attached, or if we are already in conversation about a repayment plan.

How Are Emails Hacked?

Cyber criminals don’t use black magic to hack email accounts: There are several ways your account can be accessed fraudulently.

1) Insecure Passwords

Inadequate or insecure passwords are the cause of countless hacking incidents. A password that can be easily guessed is inherently insecure. These include the word ‘password’ itself, or passwords that include personal information that can easily be looked up. A person’s date of birth, mother’s maiden name, hometown and primary school can all be found through Facebook – depending on the person’s privacy settings. Generic security questions, such as ‘where did you go to university’ offer little or no protection against someone intent on resetting your password.

The near universal practice of using the same password for most, if not all, online accounts is also a recipe for disaster. Once one password is compromised, the rest can easily be guessed or reset.

A lot of email service providers are also less secure than they should be. Within the last 12 months Google, Yahoo and LinkedIn have all suffered loss of private data through email hacking. Some of this information, linking millions of names to email addresses and passwords, can be purchased on stolen databases available through the dark web.

We recommend a policy of regular password changes for work email addresses and the use of a reputable password manager app to keep track of multiple secure passwords.

2) Phishing Messages

Phishing messages include the classic message from your bank asking you to verify your password/pin number by email, but can also be more insidious. A fraudulent message apparently from Facebook could warn you of an attempted unauthorised access to your account: ‘follow this link to confirm your password’. In a heightened state of anxiety, these messages are very easy to fall for.

Most reputable businesses now operate a policy of never requesting money or personal information through email. Be sure to check the source of an email before you respond to any requests. Also, bear in mind that sometimes, the requests look like they’ve come from someone internally and request you to make a payment – again, prior to taking the requested action, check that they have indeed made the request, particularly if they request a same day payment to be made which are impossible to recall.

Bogus incentive messages can also be used to illegally harvest data or directly commit fraud. They often include a URL link through which a piece of malware is installed on the victim’s computer.

We have received several e-mails claiming to be from customers and suppliers with an e-mail address that looks the same and asks for us to open the remittance or purchase order etc. Again, these were found to contain malware and could have had serious consequences for our business and IT systems. Others looked like simple requests for Bank Details to be updated. We have now implemented a policy of calling to verify the request with the company contact personally prior to accepting any change requests.

One way to protect yourself from these types of e-mails, is to click reply and quite often, the reply e-mail address that comes up is different to the one listed in the original message so take a second to make this simple check.

3) Malware

Computer viruses, or malware, can install itself on a PC when someone opens an infected email attachment. Some of these viruses are worms, which automatically send out the same message to every contact in the person’s email address book. Such viruses can spread very quickly around the Internet. Other malware programs include key logging software; recording the keystrokes made on a computer to determine passwords, credit card details and other information.

Keep yourself safe from malware through a strong antivirus subscription and regular scheduled scans.

Keeping Safe Online

We are not IT experts by any means, but we are concerned for the security of our customers, suppliers, employees and website visitors. We take pains to apply cyber security best practices for emails, passwords, social media and web access to keep communications safe and ensure we are a partner our customers can trust. If you are concerned about an email that supposedly comes from us, please don’t hesitate to call us for clarification. Stay safe out there.

-

THE CNC PRECISION HONING PROCESS EXPLAINED

26 March 2019CNC honing, like mostcomputer-controlled processes in general, presents some significant advantages over conventional techniques:

- Consistent and repeatable accuracy and quality

- Very fine and exacting dimensions possible

- Surface finishes of 0,05μ

- Built-in metrology controls stock removal

- Ideal for components that require the highest possible level of precision

Features and capabilities vary from machine to machine but they all deliver hands-off honing to exceptional tolerances and the ability to sense and establish the dimensions of an environment such as a target bore.

The standout advantages of a CNC honing machine are the speed and ease of setting it up for a job, size accuracy and bore geometry control.

Typical industry-wide applications are where high bore geometric tolerance is critical, for example some bearings and valve components, fuel injectors and so on. Here at Hone-All it enables us to deliver exceptional quality and balance for the wide range of components we machine and industries we serve.

General Observations

Honing generally always follows an existing machined bore. However, you may have been told that straightness and cylindricity cannot be improved upon and this is certainly the case with standard tooling used for the majority of components but specialist tooling can be designed to overcome these parameters but at an increased cost which is not always a viable option with smaller batches.

The purpose of honing is a process intended to refine a surface in terms of any or all of:

- accuracy of size

- it’s geometric form

- apply a specified surface finish, such as cross hatching

- efficient plateau honing when double acting tooling is used

What it does mean is that the position of the bore will not change relative to the external dimensions when honing to a consistent size.

What The Process Entails

The operator enters data such as parameters and material of the workpiece, initial and desired diameter, finish required, bore length, sets starting positions for stroke and feed, and presses the Start button. The rest is automatically done by computer as it calculates the stroke rate, length and spindle speed. It can optionally adjust automatically for diamond wear after the size is proven to be correct.

Within the hone head, a coned shaft is driven by either electric or hydraulic power which actuates the cone shaft to linear movement. The stone set has corresponding cone angles and the core shaft expands or contracts when the shaft is pulled or pushed. Due to the slow angle of the cones, greater accuracy is achieved.

This is powered by a motor that dynamically positions the cone, which expands or contracts to control the diameter of the stone set. It executes bore size adjustments of sub-micron proportions.

The machine self-centres in the bore to begin exploring its environment vertically and horizontally. That way it “learns” it’s starting position in relation to the part’s position and dimensions. Then it expands the stones on the hone head and is ready to execute the honing under the control of the computer and guided by the parameters entered by the operator. The honing process deploys two forces on the part - hone rotation generates torque and the push-pull stroke action provides a lateral force. Together they abrade the surface which is constantly measured by the controlling computer.

The Bottom Line

CNC honing machines deliver consistent superb precision time after time. They require little supervision after the initial setup and can repeat a program identically time after time on similar parts that may have microscopic differences in diameter or present different taper characteristics, for example. There are always those rare applications where an old-fashioned manual machine and years of engineering experience will permit a more nuanced approach. But CNC honing is fast and precise - perfect for premium quality engineered parts.

Contact Us

Take the opportunity to contact us today for an informal initial chat about your particular requirement and scenario. We are always happy to consider new and challenging jobs and delivering customer satisfaction again and again is one of our greatest strengths.

-

MAINTAINING EMAIL SECURITY & BEST PRACTICES

26 March 2019The digital economy has made a lot of things easier, including communication and payments, but these changes have gone hand-in-hand with a heightened risk of fraud from cybercrime. Internet-based fraud can take many forms. As individuals, some of us have no doubt had ‘the phone call’ from our bank questioning our recent shopping spree in South Korea. Fortunately, personal losses are usually reimbursed quickly through the bank’s insurance scheme. Risks to businesses are more profound. Companies run the hazard not only of financial loss but also loss of reputation, which can be catastrophic.

HSBC and other banks have all issued warnings to their customers not to open scam emails masquerading as coming from an official source. Unfortunately, it isn’t only banks who are susceptible to such deception.

Some of our own customers have been the victim of attempted fraud through emails purporting to come from suppliers or clients. These frequently come from a trusted email address and contain subjects such as ‘purchase order’. We were recently caught out ourselves by a so-called phishing email. Thankfully it only ended up costing us £500 but it took six weeks and a multitude of e-mails and calls to get the rest of our money back.

To avoid the risk of clients being defrauded, should our email address be misappropriated, we have introduced the policy never to request money by email unless an official statement from Hone All is attached, or if we are already in conversation about a repayment plan.

How Are Emails Hacked?

Cyber criminals don’t use black magic to hack email accounts: There are several ways your account can be accessed fraudulently.

1) Insecure Passwords

Inadequate or insecure passwords are the cause of countless hacking incidents. A password that can be easily guessed is inherently insecure. These include the word ‘password’ itself, or passwords that include personal information that can easily be looked up. A person’s date of birth, mother’s maiden name, hometown and primary school can all be found through Facebook – depending on the person’s privacy settings. Generic security questions, such as ‘where did you go to university’ offer little or no protection against someone intent on resetting your password.

The near universal practice of using the same password for most, if not all, online accounts is also a recipe for disaster. Once one password is compromised, the rest can easily be guessed or reset.

A lot of email service providers are also less secure than they should be. Within the last 12 months Google, Yahoo and LinkedIn have all suffered loss of private data through email hacking. Some of this information, linking millions of names to email addresses and passwords, can be purchased on stolen databases available through the dark web.

We recommend a policy of regular password changes for work email addresses and the use of a reputable password manager app to keep track of multiple secure passwords.

2) Phishing Messages

Phishing messages include the classic message from your bank asking you to verify your password/pin number by email, but can also be more insidious. A fraudulent message apparently from Facebook could warn you of an attempted unauthorised access to your account: ‘follow this link to confirm your password’. In a heightened state of anxiety, these messages are very easy to fall for.

Most reputable businesses now operate a policy of never requesting money or personal information through email. Be sure to check the source of an email before you respond to any requests. Also, bear in mind that sometimes, the requests look like they’ve come from someone internally and request you to make a payment – again, prior to taking the requested action, check that they have indeed made the request, particularly if they request a same day payment to be made which are impossible to recall.

Bogus incentive messages can also be used to illegally harvest data or directly commit fraud. They often include a URL link through which a piece of malware is installed on the victim’s computer.

We have received several e-mails claiming to be from customers and suppliers with an e-mail address that looks the same and asks for us to open the remittance or purchase order etc. Again, these were found to contain malware and could have had serious consequences for our business and IT systems. Others looked like simple requests for Bank Details to be updated. We have now implemented a policy of calling to verify the request with the company contact personally prior to accepting any change requests.

One way to protect yourself from these types of e-mails, is to click reply and quite often, the reply e-mail address that comes up is different to the one listed in the original message so take a second to make this simple check.

3) Malware

Computer viruses, or malware, can install itself on a PC when someone opens an infected email attachment. Some of these viruses are worms, which automatically send out the same message to every contact in the person’s email address book. Such viruses can spread very quickly around the Internet. Other malware programs include key logging software; recording the keystrokes made on a computer to determine passwords, credit card details and other information.

Keep yourself safe from malware through a strong antivirus subscription and regular scheduled scans.

Keeping Safe Online

We are not IT experts by any means, but we are concerned for the security of our customers, suppliers, employees and website visitors. We take pains to apply cyber security best practices for emails, passwords, social media and web access to keep communications safe and ensure we are a partner our customers can trust. If you are concerned about an email that supposedly comes from us, please don’t hesitate to call us for clarification. Stay safe out there.

-

ENGINEERING TALENT DISCOVERED IN BEDFORDSHIRE

26 March 2019The biggest challenge facing most UK manufacturing companies is recruiting skilled staff. It seems be at the forefront of most agendas in meetings, conferences and editorials.

The Government is trying to assist but still don’t seem to have a robust, consistent and structured approach for long term sustainability of our talent pool for engineers, technicians and machinists. Many colleges are still struggling to achieve funding for the equipment relevant to our industry today as well as in trying to recruit tutors who can inspire true passion for engineering and manufacturing.

So many various funding schemes have been trialled but too often the bulk of the funding is going to those who administer the schemes rather than the students or companies who are actually carrying out the bulk of the training.

Here at Hone-All, we provide specialist sub-contract services in Deep Hole Boring, Deep Hole Drilling, Gundrilling, Honing & CNC Turning to a wide variety of industries including Aerospace, Defence, Oil & Gas, Hydraulics and many others.

As a result of being experts in such unusual processes, in addition to a strict company policy of not “poaching” from competitors, we find it impossible to recruit skilled staff for anything other than CNC Turning and over the last few years have had numerous agencies trying to locate suitable staff to no avail.

Building Staff Skills

Having looked at our most long-standing team members and best engineers, we realised that the majority had only a slight knowledge of engineering and our processes when they started, and the rest of their expertise has been gained in-house, right here at Hone-All.

This inspired us to return to our strategy of years past and so we placed adverts on the local community Facebook pages offering the opportunity for adult apprentices to apply for a position as a trainee engineer and no knowledge or expertise was required, only a real passion for engineering and manufacturing and the right attitude – the rest we would sort!

We were amazed to receive a plethora of applications from a wide variety of the local community including Bank Managers, Retail Managers, and more!

We found so many strong applicants, we were disappointed we could only recruit 3! Our original plan was for 2 but we simply could not decide between the 3 strongest applicants and so offered one a position within our gundrilling department, one in manual honing and the other on the CNC Turning section.

One shocking discovery was that one of our applicants had done a 3-year engineering college course and had applied for over 30 jobs within engineering but had not achieved one interview in 5 years! Yes, the course was basic and did not cover a lot but the fact this young man had invested the time in the college course and continued to pursue a career in engineering despite continuous disappointments displayed to us his true passion for our industry and inspired us to give him a chance.

The question this raises for me is that companies continuously say they cannot attract engineering talent but on what basis are they assessing applications? Are candidates only interviewed if they have the exact skill required? What if they’re CV is not the most professional or attractive? Are we discriminating against applicants who may not have had assistance with writing the most professional of resumes? I guess the question is – when did we stop giving chances to those with the right attitude and a passion rather than those with a glowing CV full of technical expertise?

Adding Value To Hone-All

I know for certain that these guys are going to be a huge asset to Hone-All. Their positive attitude, approach and speed of learning has already astounded us – obviously, a fantastic reflection of the excellent training being provided by our skilled engineers – but within one single month of joining us they are already adding real value to the business.

So, my call to action or heartfelt request is, if you’re struggling to recruit, consider investing a little time, money and an open mind into your recruiting process. Consider those that may not have been at the top of the selection process originally. Spend a little time interviewing those who may not have the skills you need but have displayed a real passion for your business or our industry.

Let’s all work together to attract more talent, irrelevant of age or skill level as we all know, skills can be taught but attitude and passion cannot. Maybe then we can all benefit from a wider talent pool, fresh perspectives brought from those outside of our industry and send a real message to those within Government to help us fund this training and support properly from within our businesses, not from external administrators who have boxes to tick.

If we could achieve this, maybe our future conferences will be about the latest in innovations and best practices rather than the constant conversation regarding skills shortages – what a refreshing change that would be!

-

NEW HONE-ALL WEBSITE IS NOW READY & LIVE

26 March 2019Over the past few months we have been working hard on getting our new website ready to launch. The current website has served us well but is showing its age. The last significant update took place in 2016 and didn’t go far enough to address its structural problems – the site was a good few years old even then.

For the new website we have updated both the design and content.

New Design

You’ll notice some big improvements in how the new website looks and feels:

- Mobile responsive design: View the new website on any size screen. The site is coded so it responds to the device you are using and looks good at all screen resolutions. (We are aware that the current website doesn’t look its best on small screens.)

- Intuitive navigation: Find all the information you need from an intuitive, easy-to-use navigation menu on the homepage.

- Fast loading: All the images, video and other content on the new site are optimised for web so they load quickly on any connection speed and device – no more waiting for pages to load.