IAB Lab Ltd

Here at IAB Lab, our engineers will work with you and your architects to design structurally sound and long lasting furnishings to suit your lab specifications. Our manufacturing facility uses CAD files we supply to precisely cut and fabricate the units, these are assembled by hand and checked for any defects. Our team are skilled in dealing with bespoke projects, multidiscipline projects, or projects involving liaison via a third party.

We provide a full spectrum of products including:

- Laboratory Design

- Laboratory Furniture

- Fume Cupboards

- Fume Extraction Systems

- Mechanical Pipework

- Electrical Wiring

- Laboratory Seating

- Solid Grade Laminate Furniture (Lockers, Step Over Benches, Clothing Dispensing Units)

-

BOC Gases - Analytical and Chemistry Laboratory

7 December 2017Contract Value:- £101,000

Completed:- May 2014

Location:- Yorkshire- Service Gantries

- Maximum Bench Space

- Special Gas Services

- Mix of Plinth Mounted and Cantilevered Furniture

Another successful project for a new client that was completed on time and on budget. Working closely with the client iab designed and install the laboratory furniture, fume cupboards and over head service gantries. Working closely with the clients appointed principal contractor the job was designed, co ordinate and installed to an agreed programme. The prime consideration for the design was to provide maximum bench space for analytical equipment. To achieve this iab suggested and designed a simple steel powder coated service gantry arrangement to carry power and special gas services. The service gantries are supported from the building structure via a robust arrangement of Unistrut supports. The design provides a clear unobstructed working area across the full width of the 1500mm wide peninsular benches. The project includes fixed floor mounted furniture to the Chemistry Area and fully cantilevered benching with mobile cabinets to the Analytical Laboratories.

-

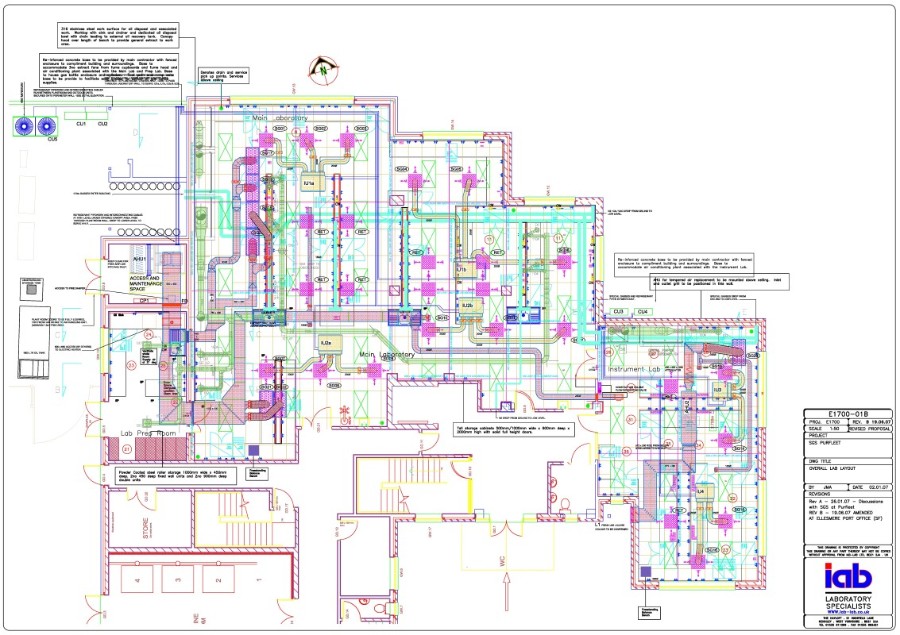

Complete Turnkey Drug Testing Laboratory Refurbishment

7 December 2017Contract Value:- £1,520,300

Completed:- December 2014

Location:- East London- Complete Turnkey Laboratory Refurbishment

- All Fixtures And Fittings

- All M&E Services

- Full HVAC System

- Special Gas Services

- Specialist Water Plant

- Nitrogen Generator Equipment

- Pumped Drainage Systems

- Large +5c Cold Room And -20c Freezer Room

One of iab’s regular and valued client was moving their drugs testing lab. As part of this major relocation iab were appointed to design and construct a series of new laboratories and offices to accommodate the existing business and provide space for expansion. The £1.5million project was designed and built to a tight program, 20 weeks in total including the demolition of the existing interior fit out and the installation of the new areas complete with all fixtures and fittings; M&E, HVAC, special gas services, specialist water plant, nitrogen generator equipment, pumped drainage systems, large cold room and freezer room and first floor offices and meeting rooms for 80 to 100 staff. This project represents a major investment for one of iab’s leading customers and marks a major turning point for iab in its development and target to become a leader in the laboratory design and build market.

-

Geosciences Laboratory - Design and Build

7 December 2017Contract Value:- £2,609,300

Completed:- December 2015

Location:- Conwy, North Wales- Complete turnkey Geosciences laboratory design and build

- Specialist Water Discharge Plant

- Full HVAC System

- Full M&E Services

- Special Gas Services

- Specialist Water Treatment Plant

- Water Wash Fume Cupboards & Extraction

Our client, a leading specialist in the Geoscience Market, provides comprehensive solutions to challenging Geophysical and Geological complexities encountered during the exploration and production of the earth’s natural resources. The business is a global leader in geosciences and are well known and respected throughout the world, as a result of their extensive experience in virtually every known and potential hydrocarbon province.

iab are pleased to present the successful completion of this £2.6 million design & build laboratory and warehouse project. The project, completed in iab’s 25th year of business, demonstrates that iab and its network of contractors have the ability to perform and deliver a complex design and build contract on budget and time.

From an initial client scope of works prepared by Capita Consultants, iab were employed to develop the project. The business designed and converted an existing office and large warehouse building into a fully functioning series of laboratories, plant rooms, offices and warehouse space. The existing building provided 1440m2 of office and storage. The conversion transformed the space into a facility with 2300m2 of floor space.

External works included new equipment zones, a plant gantry, HVAC plant and equipment, new utilities for power, gas and water supplies, additional drainage for the laboratories, three stage settlement tanks and a 24 hour standby generator.

The internal plant was housed in two dedicated plant rooms. These provided space for boosted mains and boosted tank cold water, boilers for both tank and mains water and TREND BMS controls. A separate plant room was provided and dedicated to the new mains incoming supply, generator cabling, automatic switch over panel and mains distribution board for the building.

The ground floor area was developed to provide a sizeable warehouse for samples, site equipment storage, engineer’s workshop and a dedicated bunded plant room for a specialist waste water treatment plant. The open warehouse areas was fitted out with static racking.

The first floor laboratories were constructed on a purpose built mezzanine floor which extended the length and full width of the existing warehouse. Partitions to these areas were constructed from the mezzanine deck up to the underside of the metal clad sloping roof to provide individually sealed laboratories. Each laboratory contained laboratory benching, fume cupboards, fume hoods (canopy and cone) fume extract systems, replacement air supplies, and close control recirculating air conditioning. Air conditioning provided from energy efficient VRF AC equipment. This floor also included the male and female changing rooms for laboratory staff, laundry area, cleaner’s store, emergency equipment store, acid and solvent store. To service the east elevation of the building access was provided to the external plant gantry, via a hoop ladder, which supports 13 individual fume extraction fans. The rear of the building also included a platform lift for passenger and samples and a dedicated internal fire escape.

To handle the hazardous processes associated with the preparation of geological samples, a large laboratory was formed as part of the overall scheme to provide space for cantilever perimeter and peninsular benching and eight 2000mm wide recirculating water wash fume cupboards. This part of the project together with another major processing area was designed to deliver an air supply system that provides temperature control and a large amount of replacement air. The Bivalent designed air handling plant is serviced from air source heat pumps and direct gas fired heating which enables the temperature to be closely controlled during summer and winter months. The direct gas fired heating system provides an additional heat source when the outside temperatures fall excessively during the winter months.

In addition to the main HVAC plant and Mechanical and Electrical Services a clean air Duplex compressor system was installed providing a run and standby facility. The compressor equipment is placed external to the building in a dedicated, ventilated, heated, weather and sound proofed enclosure. To service a high profile GC Laboratory, bottle gas services have been installed to supply Oxygen, Helium and Liquid CO2. Hydrogen and Nitrogen are generated from under bench Nitrogen and Hydrogen Generators.

Throughout the laboratories energy saving LED lighting has been installed to provide a cost effective installation and excellent level of lighting with built in self testing emergency lights.

The geosciences laboratory design and build contract was administered under a JCT, DB2011, Design and Build Contract. The contract administration and CDM management was carried out by Capita, Colwyn Bay.

- External Plant Gantry and Plant Base for HVAC Plant and Fume Extract Equipment

- New Utilities – Mains Gas Supply – Mains Water Supply – Mains Power Supply.

- External Underground Drainage and Interceptor Settlement Tank.

- 24 hour Automatic Standby Generator

- New External Windows.

- Internal Blockwork Walls.

- Mezzanine Floor, Staircase and Platform Lift.

- Warehouse Shelving.

- LPHW fan assisted heating system to Warehouse

- Domestic Mains Water System

- Domestic Mains Hot Water System

- Boosted Tank Cold Water. (Laboratories)

- Boosted Tank Hot Water. (Laboratories)

- Vulcathene Drainage & Sinks

- Duplex Run and Standby medical air external compressor and distribution pipework

- External compressor housing

- External Bottle Store, Run and Standby Gas Manifolds, Distribution Pipework for Hydrogen, Nitrogen, Oxygen, Helium and Liquid CO2.

- New Power Distribution within the Building

- LED Lighting, Emergency Lighting, CCTV Installation, Fire Alarm System, Electronic Door Access, Small Power Distribution, 3 Compartment Trunking.

- Data installation, containment, COMMS Cabinet

- HVAC Installation, Laboratory Pressure Profile, Variable Air Replacement, VRF Installation, Air Handling, Distribution Ductwork

- Trend BMS Controls

- Controls Cabling

- Power Distribution to plant and equipment

- Cantilevered Laboratory Benching, Mobile under bench cabinets

- Trespa Athlon Worktops

- Solid 20mm thick Polypropylene Worktops

- Bespoke Designed and Manufactured 316 Acid Stainless Steel Sample Wash Down Sink Modules

- 2000mm wide Recirculating Water Wash Fume Cupboards with Linked Extraction Systems.

- Standard 1200mm wide Fume Cupboards and Extraction Systems

- Bespoke Fume Hoods and Individual movable Alsident Hoods.

- Manual and Automatic Waste Tank Discharge Systems to Beckart Treatment Plant

-

Cannon Hall, Educational Kitchen

6 December 2017Contract Value:- £5,200

Completed:- May 2015

Location:- Barnsley, South Yorkshire- Soild Grade Laminate Furniture

- Plinth Mounted Units

- HI-MACS Confetti Quartz Worktop

Following an internet search for lab refurbishment companies, we received an enquiry in from Rance Booth Architects via our website. They required advice on a laboratory style, solid grade laminate educational kitchen that they were designing as part of a new educational facility for Cannon Hall. Over a period of around 3 weeks, we helped them design a small practical educational kitchen that would meet all the clients needs.

We chose to use a range of bespoke solid grade laminate cabinets as these would meet the high demands and day to use that the kitchen would need to withstand.

The design was a simple straight run of mainly standard height units, with a lower height sink for smaller children and disabled people because this was needed to be a fully functioning kitchen. We also installed normal appliances, like a under counter fridge and a modem range style double cooker. At the request of the client we used a HI-MACS Confetti Quartz Worktop that matched other worktops elsewhere in the facility.

-

Solid Grade Laminate Lockers - Amec Foster Wheeler, Warrington

6 December 2017Contract Value:- £11,000

Completed:- October 2017

Location:- Birchwood, Warrington- Solid Grade Laminate Lockers

- Sloped tops

- Changing bench

- Handwash station

We were approached by Wood PLC (Previously Amec Foster Wheeler) – Warrington to design, supply and install a new solid grade laminate locker room. This was in addition to the refurbishment of office and laboratory areas.

The client wanted a long lasting durable product that was easy cleaning. With our vast expertise, we recommended that the lockers had a ‘sloped top’. This would enable easy cleaning without any dust traps, As well as providing an attractive finish to the lockers. To continue with the attractive finish, we installed side panels in the same colour as the lockers and tops to the exposed sides of the locker. This hid any unsightly screw finishes. The lockers have been manufactured with a top of the range self-closing hidden hinge. Number engraving was added to each locker. Along with our standard cam lock.

A changing bench was manufactured and installed in the centre of the room with stainless steel coat hooks and a wall mounted a set of coat hooks. The hand wash station was also manufactured in solid grade laminate in the same colour as the lockers which was built into a storage cupboard.

-

Bradford University - Bespoke Mobile Tables

6 December 2017Contract Value:- £67,490

Completed:- November 2016

Location:- Bradford, West Yorkshire- Bespoke Mobile Tables

- Electric Height Adjustable Tables

- Cable Pass Though Ports

73 bespoke mobile tables and 2 electric height adjustable tables were designed and produced by iab for Bradford University in their most recent project. iab completed the design stage of this project in under 3 weeks creating mock models to show the client for approval before putting them into full manufacture. The benches consisted of Silver powder coated steel framework and Icey Blue 16mm Trespa Toplab Base, complete with multiple cable ports, powder coated steel cable shelving and a 15mm melamine vanity panel. The end users were extremely pleased with the job that iab carried out.

-

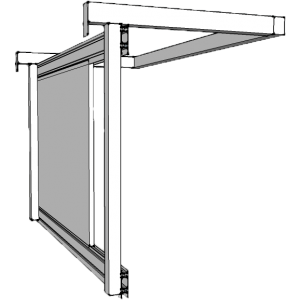

Warwick Chemicals Walk In Fume Cupboard

6 December 2017Contract Value:- £21,303

Completed:- April 2016

Location:- Holywell, Flintshire, North Wales- Custom Made Walkin Fume Cupboards

- Re-used Existing Extraction System

- Cable Pass Though Port

From initial discussions with the client, iab prepared a design to replace 2no existing fume cupboards. The objective was to provide one large walk in fume cupboard, separated by 2no sets of 3 part sliding sashes. To minimize expenditures, the existing fume extract system was assessed and the existing extraction system was utilized.

After a 2 week design period we submitted a design to the client for the walkin fume cupboard that we felt would meet their requests. Once the design was approved, the unit was put into production. Overall the job took us approximately 6 weeks. Before being installed, the unit was provisionally put together by our sub-contractors – this meant that we could complete onsite installation in only 2 days.

To maximize usable space within the fume cupboard, the water supply and drainage was recessed into the left and right hand structures.

A fundamental part of the design was to eliminate trailing power cables from the external 13amp sockets and reduce the risk of power cables being caught by the 3-part sliding sash. To overcome this hazard, access ports were provided to the central service column, and the left and right hand service structures. Incorporation of the access ports eliminated trailing leads from the power cables and other service pipework from external pieces of the client’s equipment.

The client was extremely pleased with the outcome and is happy for us to conduct future works for them.

-

National Resources Wales, Full Turnkey Lab Refurbishment

6 December 2017Contract Value:- £1,200,000

Completed:- January 2017

Location:- Swansea, South Wales- Full Turnkey Lab Refurbishment

- Detailed Laboratory Design

- Safe Roof Top Plant Area for HVAC & Fume Extraction

- Large Special Gases Plant and Storage

Natural Resources Wales (NRW) have recently taken occupation of a new laboratory facility at Swansea University, Singleton Campus. The laboratories have been designed and constructed by iab-lab Limited to replace NRW’s old laboratories at Llanelli. In keeping with iabs philosophy of detailed consultation with every client the scheme was put together to provide laboratories and office space in the Faraday Building and adjacent Faraday Tower. The location of the new development provides open access to all of the Universities on site amenities providing staff with a greatly improved working environment. As seen in the pictures new HVAC and fume extract equipment has been placed on the roof of the building providing a safe open area for maintenance of plant and equipment. The furniture fit out provides fixed cantilevered benching and mobile instrument benches. The success of this job started and finished with close cooperation between iab and NRW staff and managers.