Kohesi Bond

Kohesi Bond is a pioneer in manufacturing custom engineered adhesives, sealants, coatings, potting and encapsulation compounds. In November 2014, we started prototyping as a part of an interdisciplinary effort with the Institute of Chemical Technology, bringing together a team of technical experts to formulate specialty adhesive systems. Through persistent research, technical know-how and groundbreaking innovation we were able to create new compounds that had truly distinguished properties. In September 2015, we founded Kohesi Bond to further our research and manufacture first-rate, industry-ready products in our state of the art facility.

To deliver reliable solutions, we realised that one size does not fit all. Hence, our focus has been on offering tailor-made products, consistent quality and unparalleled expertise to our customers. We want to keep innovating new products with diverse chemistries that add more value to every application. By researching, formulating and testing each product all under the same roof, we are able to take a holistic approach to manufacturing exclusive adhesives and provide customers with an end-to-end solution.

THERMALLY CONDUCTIVE ADHESIVES

Kohesi Bond’s thermally conductive epoxies provide phenomenal heat dissipation properties. These first-rate heat transfer materials are widely used in a variety of industrial applications, especially in the electronic industry. Some of the applications include heat sink bonding, power semiconductor devices, BGA die attachment using a heat spreader, potting and encapsulation of sensors and chip-scale packages (CSP). Our thermally conductive products offer serviceability at extremely low and high temperatures, superior mechanical strength, dimensional stability, chemical resistance, and electrical insulation. Special silver/ silver-coated nickel/ nickel filled systems are also available that provide excellent heat transfer properties, along with electrical insulation.Our custom made adhesives, sealants, coatings, potting and encapsulation compounds can be formulated to meet more than one of the aforementioned properties in your application. In addition, our products are capable of passing a number of industrial certifications, such as NASA low outgassing (ASTM E-595), USP Class VI and UL 94V-0 flame retardance, among others.

POPULAR PRODUCTS

-

TUF 1820 AOHT: TUF 1820 AOHT is our one part, toughened epoxy system that offers phenomenal thermal conductivity. It requires no mixing and cures rigid at elevated temperatures. This halogen free product offers outstanding physical strength properties.

-

KB 1040 AOHT: KB 1040 AOHT is a two component, easy to use epoxy system offering superior thermal conductivity. It offers good flow properties, mechanical strength and cures rigid.

-

KB 1372-AO: KB 1372-AO is our two component, heat curing epoxy system. In addition to first-rate thermal conductivity, this epoxy offers outstanding chemical and high temperature resistance.

SODIUM SILICATES

Kohesi Bond’s “KB-SS” series of products are uniquely designed sodium silicate based systems. Sodium silicates are inorganic aqueous based systems that are commonly known as “water glass” or “liquid glass”. These one component products require no mixing and are widely used for bonding and coating applications. In addition to being odourless and fire-resistant, they are notable for their phenomenal resistance to extremely high temperatures up to 370°C. Sodium silicates offer excellent adhesion to a wide range of substrates including various metals, plastics, ceramics, composites and glass. They can be cured at room temperature as well as at elevated temperatures.

POPULAR PRODUCTS

KB-SS-SIL: KB-SS-SIL is a one component, aqueous, sodium silicate based system. This silver filled electrically conductive product forms a superior moisture barrier and is preeminently used as a coating for effective shielding against EMI and RFI.

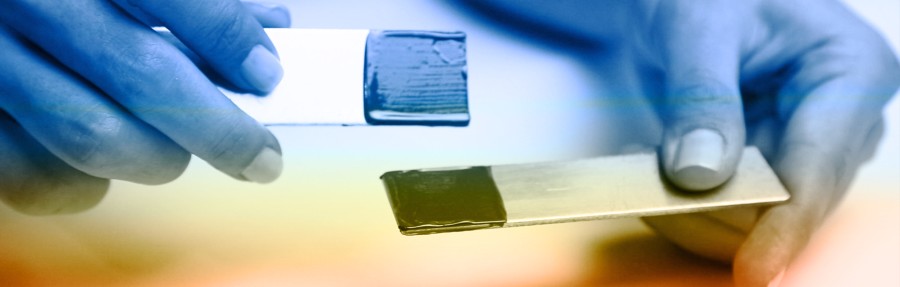

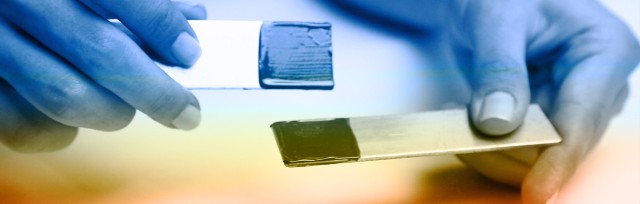

BONDING

Kohesi Bond manufactures an extensive range of epoxies for bonding similar and dissimilar substrates. Our one and two component adhesives can bond over small and large surface areas and offer first-rate adhesion. Our bonding epoxies can be cured at room temperatures as well as elevated temperatures and offer a broad range of cure times to suit your requirements. They are available in different hardnesses, viscosities and working times. These mechanically strong adhesives are typically used to bond various metals, ceramics, glass, plastics, rubbers and composites. In addition, our products offer excellent dimensional stability, very low shrinkage and can withstand temperatures over a wide range. Kohesi Bond adhesives are well known in the electronics, medical, food, optical, chemical and oil and gas industries. We can customize each adhesive to meet your specific end requirements.

POPULAR PRODUCTS

TUF 1820 AOHT: TUF 1820 AOHT is our one component, heat curing epoxy system. This product offers outstanding adhesion to various substrates and very high lap shear strength.

SEALING

Kohesi Bond’s world class one and two component sealants offer ideal solutions to sophisticated and challenging industrial applications. These 100% reactive systems offer an assortments of properties, such as chemical resistance, optical clarity, resistance to thermal cycling, thermal and electrical conductivity and superior mechanical strength. They are widely used in various aerospace, oil and gas, chemical, electronic, optical, automotive and speciality OEM applications. Our products are available in various packaging options and offer easy of use as well as application. Our custom formulated sealants are typically used for sealing in MEMS, optical devices, semiconductors, electronics, industrial ovens and similar applications.

POPULAR PRODUCTS

KB 1613 HT: KB 1613 HT is our one component, heat curing epoxy system. It offers superior electrical insulation, dimensional stability and it can be serviced over a wide temperature range.

COATING

Kohesi Bond custom formulates epoxy and sodium silicate based coatings for specialty applications. Our coatings offer excellent protection against chemicals, moisture, abrasion, mechanical and thermal cycles and shocks, extreme temperatures and UV. Our products are available in varying viscosities and hardnesses. In addition, specific grades offer phenomenal electrical and thermal conductivity or insulation, based on your end application. Our industrial coatings are capable of meeting various industrial certifications, such as NASA standards for low outgassing (ASTM E-595), USP Class VI and FDA food standards. These coatings are commonly used for conformal coatings, reduction of friction, wear resistance, chemical or corrosion resistance and EMI/RFI shielding, among others. We can customize our coatings to meet your specific application requirements.

POPULAR PRODUCTS

-

KB – SS - G: KB-SS-G is our one-part, graphite filled, sodium silicate based coating. It offers superior electrical conductivity and is ideal for EMI/RFI shielding applications. Additionally, it is also used for grounding and static discharge.

POTTING / ENCAPSULATION

Kohesi Bond specializes in formulating superior epoxy based potting and encapsulation compounds. For good potting, encapsulation or casting, epoxies need to offer very good dimensional stability, low exotherm, forgiving working times, low shrinkage and stress free adhesion to housing substrates. Our potting and encapsulation epoxies can be customized to meet all of the above requirements. In addition, they also offer good thermal management properties, very low coefficients of thermal expansion, resistance to high as well as low (down to cryogenic) temperatures and outstanding chemical resistance. These products are used for potting of various electronic and microelectronic components, such as sensors, motors, coils, transformers, capacitors, switches, connectors, power supplies and cable harnesses among others. We offer our products in a variety of packaging options for manual as well as automated dispensing. They offer ease of application and reliable, consistent results. Special grades can meet NASA standards for low outgassing (ASTM E-595), USP Class VI biocompatibility, FDA standards and UL flame retardancy. Kohesi Bond’s specialty lies in customizing products to your requirements.

POPULAR PRODUCTS

KB 1631 FR – 2: KB 1631 FR-2 is our two component flame retardant potting compound. This epoxy based system is capable of passing UL 94V-0 test and produces extremely low smoke. Also, it contains non-halogenated fillers.

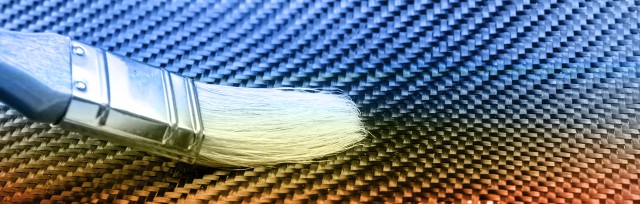

IMPREGNATION

Impregnation of micropores in metals, ceramics, fibers and other materials requires low viscosity, stable and strong compounds. Kohesi Bond’s first-rate epoxies offer a choice of long open time, low viscosities, superior strength, dimensional stability and wide service temperature ranges. In addition the offer excellent chemical resistance and cure readily at elevated temperatures. Our products are commonly employed with glass and carbon fiber mats for use in aerospace, windmill and high-end electronics applications. We can customize our products to meet specific end user specifications.

POPULAR PRODUCTS

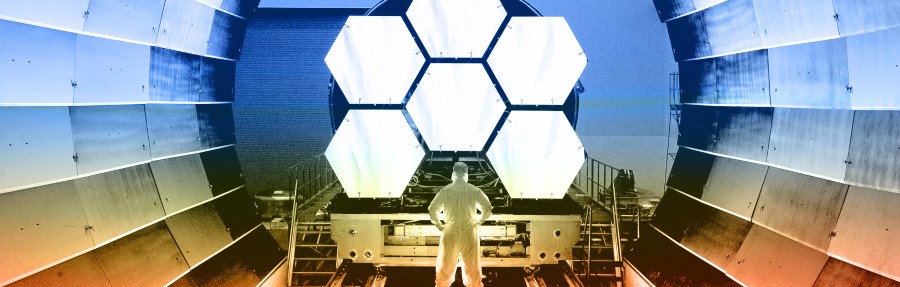

AEROSPACE ADHESIVES

Kohesi Bond is a pioneer in manufacturing first-rate adhesives, sealants, coatings, potting and encapsulation compounds, designed specifically for use in the aerospace industries. We offer an extensive range of one as well as two component epoxies and sodium silicate based systems that meet the stringent requirements of this industry. Specific grades are capable of passing NASA standards for low outgassing (ASTM E-595), UL94V-0 and FAR 25.853 (a) flame retardancy tests. These adhesive systems are commonly employed in the manufacture of airplanes, helicopters, rotorcrafts, satellites and unmanned aerial vehicles (UAVs). Our unique products offer the desired structural strength, chemical resistance, high as well as low temperature resistance and extremely low flame, smoke and toxic emissions (FST). Typical applications include defense and aerospace electronics, aircraft interiors and structural bonding. Kohesi Bond specializes in customizing our products to meet your exact design specifications to provide improved performance, weight savings, durability and ease of application.

POPULAR PRODUCTS

-

KB 1031 AT-S: KB 1031 AT-S is a two component epoxy system that cures readily at room temperature. This silver filled system offers outstanding electrical conductivity and first-rate peel strength.

-

KB 1600 FR-V: KB 1600 FR-V is our two component epoxy system that is capable of passing FAR 25.853 (a) standards for flame retardancy. It contains non-halogenated fillers and it is ideal for use in aircraft interiors.

-

KB 1040 P: KB 1040 P is our two part, room temperature curing epoxy system. It offers superior optical clarity and adheres extremely well to plastic substrates.

KB 1039 CRLP: KB 1039 CRLP is a two component, heat curing epoxy system. It offers first-rate optical clarity and can withstand cryogenic temperatures. In addition, it is capable of passing NASA standards for low outgassing (ASTM E-595).

ELECTRONICS & ELECTRICAL ADHESIVE

Kohesi Bond is at the forefront of manufacturing one and two component epoxy and sodium silicate based systems, primarily formulated for the electronics and the electrical industries. These specially designed adhesives, sealants, coatings, potting and encapsulation compounds meet the highest quality standards. Also, they are capable of passing various industrial certifications such as NASA standards for low outgassing (ASTM E-595) and UL 94 V-0 for flame retardancy. Our superior products offer superior electrical and thermal properties. Specific grades offer first-rate electrical conductivity for shielding, wire bonding and grounding applications. They adhere well to similar and dissimilar substrates and provide excellent dimensional stability. Our products can withstand extremely high and low temperatures, harsh chemical environments and offer low coefficient of thermal expansion (CTE). We can tailor our products to match specific curing and flow properties. In addition, our easy to use packaging allows for minimal waste and can be readily used with automated dispensing machines. Typical applications include conformal coating, die attach, glob top, surface mounting, underfilling, EMI/RFI shielding, PCB and semiconductor manufacturing and packaging, among others.

POPULAR PRODUCTS

-

TUF 1613 HT-GT: TUF 1613 HT-GT is our one part, one component, heat curing epoxy system. It is ideal for glob top applications and it offers superior dimensional stability.

-

TUF 1613 HT-SM: TUF 1613 HT-SM is a one component, surface mount epoxy adhesive. It offers rapid cures at elevated temperatures and offers phenomenal toughness.

-

KB 1613 RLV: KB 1613 RLV is our one component, low viscosity epoxy system. It rapidly cures at elevated temperatures and flow well under small gaps, ideal for underfill applications.

-

KB 1689: KB 1689 is our silver coated nickel filled epoxy system. This two component adhesive readily cures at room temperature and offers first-rate electrical conductivity and cost effectiveness.

TUF 1613 HT-CM: TUF 1613 HT-CM is our one part, chip coating epoxy adhesive. It offers excellent thermal conductivity, ideal dispensing profile, superior electrical insulation and toughness. Additionally, it is capable of passing NASA standards for low outgassing (ASTM E-595).

OPTICAL ADHESIVES

Kohesi Bond’s performance products are the industry standard for optical applications. Our products offer first-rate optical clarity, match refractive indices with commonly used substrates and superior non-yellowing properties. In addition they provide various electrical, thermal and chemical resistance properties. They are available in varying viscosities and adhere well to a wide range of substrates, such as glass, quartz, metal, various plastics and optical fibers. In addition, they are capable of passing NASA standards for low outgassing (ASTM E-595). Our unique one and two component epoxy adhesives are can be customized to meet specific requirements of the optical industry. Typical applications include fiber optics, light emitting diodes (LEDs), laser devices, electro-optical devices, photonics and display devices.

POPULAR PRODUCTS

-

KB 1039 CRLP: KB 1039 CRLP is an optically clear, two-part epoxy that offers long working life and low exotherm. This product is cryogenically serviceable and offers excellent flow properties. It can transmit well over 96% in the 300 nm to 2000 nm range of wavelengths.

-

TUF 1828 TC: TUF 1828 TC is a special one component adhesive that is cryogenically serviceable and can be applied in extremely thin sections. This low thermal resistance product offers a thermal conductivity of > 3.4 W/m/K.

-

KB 1631 HTC-1: KB 1631 HTC-1 is our two specialty two component epoxy system that offers phenomenal thermal conductivity, dimensional stability and a very low CTE of 15 - 20 × 10-6 in/in/°C. It is cryogenically serviceable and it is capable of passing NASA standards for low outgassing (ASTM E-595).

KB 1031 SPLV-6: KB 1031 SPLV-6 is our two component epoxy compound, that offers a convenient to use mix ratio of 1:1. It offers a long pot life, low exotherm and excellent electrical insulation making it ideal for potting and encapsulation.

OIL & CHEMICAL ADHESIVES

Kohesi Bond is a leading manufacturer of epoxy based systems for the oil and chemical industries. Our cutting edge products offer first-rate resistance to chemicals, abrasion and high and low temperatures. They provide excellent adhesion to an arrow of substrates and hold up to extreme environments. Our products are available in varying viscosities and curing properties, providing ease of use during production as well as maintenance. These adhesives, sealants and coatings have been commonly employed in upstream, midstream and downstream applications. We can also customize our products to help engineers meet their specific requirements. Typical applications include oil and gas manufacturing, petrochemical refineries, corrosion resistance,

POPULAR PRODUCTS

-

KB 1372-LO: KB 1372-LO is our two part, heat curing epoxy system. It offers excellent high temperature resistance and it can withstand severe chemical exposure, especially acids.

-

TUF 1452 HT-2: TUF 1452 HT-2 is our two part, toughened epoxy system. It offers excellent mechanical strength properties, resists shocks and impacts and can withstand severe chemical exposure.

-

KB 1040 QF: KB 1040 QF is our two component, quartz filled epoxy system. It offers excellent abrasion resistance and can withstand various chemicals.

KB 1039 CRLP-AO: KB 1039 CRLP-AO is our two component, heat curing epoxy system. It offers first-rate thermal conductivity, can withstand cryogenic temperatures and it is ideal for potting and casting applications.

MEDICAL ADHESIVES

Kohesi Bond’s superior medical grade epoxies are uniquely formulated to meet the challenges of this industry. We offer a comprehensive range of one and two component epoxy systems that can be cured at ambient and/or elevated temperatures. Our products are capable of passing USP Class VI and ISO 10993-5 biocompatibility tests. In addition, they can withstand multiple cycles of autoclaving, ethylene oxide (EtO) sterilization, radiation sterilization and other cold sterilants. They offer excellent adhesion to similar as well as dissimilar substrates, dimensional stability and resist high temperatures. Our adhesives cure in a broad range of hardnesses and can be packaged for automated dispensing. Our ability to craft each product to your specific requirements, makes our products ideal for use in medical applications. Typical applications include medical electronics, needle bonding, reusable and disposable devices, diagnostic equipments, prosthetics and orthopaedics.

POPULAR PRODUCTS

KB 1031 AT-S: KB 1031 AT-S is our two component, silver filled, electrically conductive epoxy system that is capable of passing USP Class VI testing and offers good toughness.

OEM ADHESIVES

Kohesi Bond extensive range of one and two component epoxy systems are carefully designed for use in various OEM applications. Our products offer convenient cure schedules, easy-to-use mix ratios and varying viscosities to meet your requirements. The are also capable of handling extreme temperatures and chemical exposure. Our adhesives, sealants, coatings, potting and encapsulation compounds are commonly used filters, engines, cryogenic freezers, hydraulic components, pumps, transformers and semiconductor assemblies. They offer superior adhesion to similar as well as dissimilar substrates. Kohesi Bond specializes in customizing each product to specifically meet your end requirements. Also, we offer our products in easy to use packaging.

POPULAR PRODUCTS

TUF 1452 HT-2: TUF 1452 HT-2 is our two part, toughened epoxy system. It offers excellent resistance to high temperatures and various chemicals.

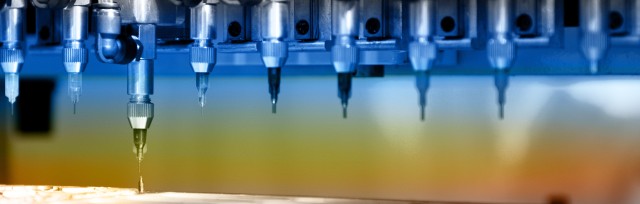

SYRINGES & CARTRIDGES

Kohesi Bond offers syringe and cartridge packaging options for our one as well as two component adhesive systems. This type of packaging offers ease of use and accurate dispensing. Dispensing can be done either manually or automatically. Our syringes and cartridges are compatible with both dispensing techniques. They are available in various sizes; starting from 3 cc to upwards of 60 cc. These syringes and cartridges are capable of handling varying viscosities and can be custom packed to meet your specific requirements.

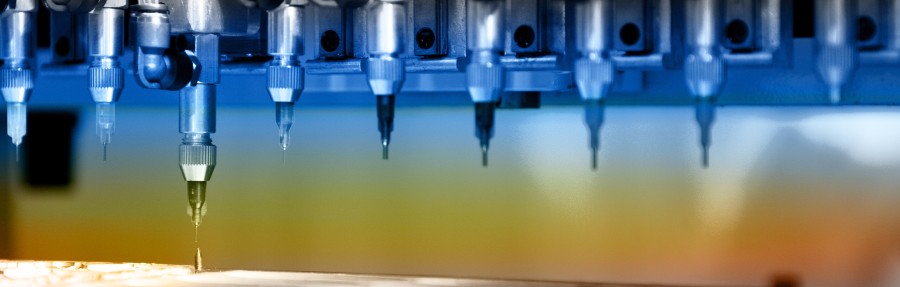

GUN APPLICATOR

Kohesi Bond’s first-rate two component epoxy systems can be packaged in our innovative gun applicators. Our gun applicator kit typically consists of a gun applicator, double barrel adhesive cartridge and mixing tubes. They eliminate the need for manual metering and mixing. It ensures that a specific quantity of Part A and Part B is dispensed out of the cartridge, depending on their mixing ratio. Once the epoxy and the hardener are squeezed out of the cartridge, they flow through a mixing tip. This mixing tube ensures complete mixing of the two components each time. Epoxy systems having mixing ratios of 1:1, 2:1, 4:1 and 10:1 can be used with gun applicators. Gun applicators offer ease of use, accurate mixing and dispensing and consistent results.