Why Elastometers Matter in Bioreactors?

2 December 2019Biocompatible wetted materials are important to avoid contamination. Learn about the importance of these components in Bioprocessing applications, with this article from Alicat Scientific - the leading company in flow solutions.

An article by Mic Chaudoir and Zane Forier

Bioprocessing has very specific requirements for wetted materials, in order to avoid contamination of the bioreactor environment. One of the potential contaminants are materials outgassed from elastomers, typically adsorbed onto elastomers during polymerisation.

While outgassing most commonly occurs under vacuum conditions, it can be a concern in any situation where a pressure drop is present (such as gas input lines for bioreactions). A number of studies have demonstrated outgassing from elastomeric components under a variety of conditions.1

Outgassed components are of concern as they are thought to be inhibitory towards microbial growth and have been shown to have toxic effects in whole animal studies.2

The ASME Bioprocessing standards call out for specific materials used in the construction of bioprocessing equipment.3

While mass flow meters typically lie outside of the sterile boundary and do have contact with the final product, it is still good practice to follow the BPE-2016 standards.

Many high performing mass flow meters utilise elastomers to take advantage of this material’s superlative sealing properties, which result in lower leak rates and higher precision mass flow measurement. Mass flow meters also require rigid materials (ranging from inexpensive ABS plastics to exotic stainless steels) for their flow bodies and process connections.

Outgassing is a concern, as outgassed components would likely pass through sterilizing filters and are a potential source of process contamination. Therefore the BPE-2016 standards are often applied to mass flow meters, regardless of their position relative to the sterile boundary. 316L stainless steel can be used for elements in the flow path, including flow bodies and laminar flow elements.

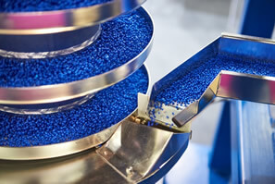

Less frequently considered, but of greater potential concern are the elastomeric components used in high-performance mass flow meters. The BPE-2016 standards recommend using certain corrosion-resistant, high durability elastomers, including EPDM (Ethylene Propylene Diene), FKM (Fluoroelastomer) and FFKM (perfluoroelastomer).

The standards further recommend USP VI Elastomers for components likely to be in contact with the final product being produced, or with liquids in the same environment. If this is a concern, only USP Class VI elastomers with good permeation resistance should be used.

Outgassing is only able to occur after materials have first been permeated – so resistance to permeation is the critical factor in preventing subsequent outgassing. Marco rubber and plastics has published a nice comparison of permeation rates of common elastomers indexed with commonly used gasses.4

Additionally, elastomers used can also be FDA certified. USP Class VI and FDA certified elastomers have minimal reactivity and are certified safe for hygienic use.5,6

While Alicat uses several types of elastomer in several products, Viton brand FKM (Fluoroelastomer ASTM D1418) meets the BPE 2016 standards, as well as being available in USP Class VI FDA certified form. Viton branded FKM also carries the implicit guarantee of Dupont’s high-quality manufacturing standards. Viton’s outstanding sealing characteristics, permeation resistance, high performance and available certifications mean that it’s often the preferred elastomer for these applications.

It is also good practice to use only Animal-Derived Ingredient (ADI) free products in bioprocessing. This avoids another potential source of contamination, as well as being an ethically sound practice. Choosing a mass flow meter which meets these requirements for compatibility should be an important part of any purchasing decision – and helps avoid potential contaminations of bioprocesses.

Lab Unlimited and Alicat Scientific are very aware of the need to prevent contamination of the fragile bioprocessing ecosystem. This includes the use of appropriate wetted materials, minimal outgassing and products free from contamination.

Contact us today to see how we can help you improve your Bioprocess application with fast, precise and clean flow.