Biocompatible UV Curable Adhesive Formulated for TPU Bonding

10 June 2022Biocompatible UV Curable Adhesive Formulated for TPU Bonding

Master Bond UV17Med is a one part, no mix, UV curable system. It was specially formulated to provide excellent adhesion to many TPUs (thermoplastic polyurethanes), which are widely recognized as challenging substrates for bonding. This compound provides very good toughness with a high elongation of 50-60%. UV17Med passes stringent ISO10993-5 cytotoxicity standards.

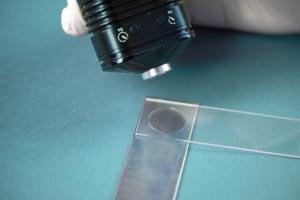

UV17Med cures in 10-30 seconds when exposed to a UV light source emitting at a wavelength of 320-365 nm with an energy output of 20-40 milliwatts/cm2. It is recommended that one of the surfaces to be bonded is transparent, without UV blocking agents, so as to allow the light to penetrate the substrate’s surface with no shadows. This flowable system features a low viscosity of 500-3,000 cps, a tensile modulus measuring between 30,000-50,000 psi, and a service temperature range from -80°F to 250°F.

This non-cytotoxic system is formulated for demanding applications in the medical industry, and is capable of withstanding many chemicals including liquid sterilants, antimicrobial agents, Ethylene Oxide (EtO), e-beam, and gamma radiation. In addition to TPUs, UV17Med bonds well to metals, glass, ceramics and many plastics. It is available in a wide range of packaging options, including ½ pint, pint, quart, gallon and 5 gallon containers. It can also be purchased in convenient syringe applicators for automated dispensing.