Thermally Conductive, Electrically Insulative Epoxy for Medical Device Applications

1 August 2023

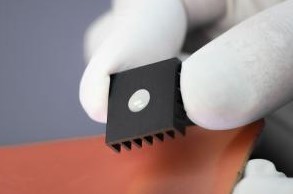

Master Bond EP40TCMed is a two part, room temperature curing epoxy system that meets the requirements of ISO 10993-5 for non-cytotoxicity. It is thermally conductive, electrically non-conductive and can be utilized as an adhesive or sealant in various medical and wearable device applications.

This toughened epoxy delivers an elongation of 60-70%. It has good strength properties with a tensile lap shear strength between 2,300 and 2,500 psi, a T-peel strength of 40-60 pli and a low tensile modulus of 5,000-15,000 psi at room temperature, making it ideal for applications where low stress is needed. The system’s small particle size filler allows for effective heat transfer when applied in thin layers, lowering its thermal resistance. It is also capable of withstanding exposure to EtO, radiation and several sterilants, as well as anti-microbial cleaning agents. Serviceable from -100°F to +300°F [-73°C to +149°C], EP40TCMed features reliable electrical insulation characteristics with a dielectric constant of 4.4 at 60 Hz and a volume resistivity greater than 1015 ohm-cm. Its thermal conductivity is 8-11 BTU•in/(ft2•hr•°F) [1.16-1.60 W/(m•K)].

EP40TCMed offers convenient handling with a 1:1 mix ratio by weight, and has a relatively long working life of 2-3 hours for a 100 gram batch of mixed epoxy at 75°F. After mixing, the epoxy has a moderate viscosity of 80,000-100,000 cps, which is useful for applications where some, but not too much flow is required. Upon cure, it has low shrinkage and a hardness of 70-80 Shore D. EP40TCMed comes in standard sized units of ounce jars, ½ pint, pint, quart, and gallon kits. It is also available in premixed and frozen syringes.

Request a technical data sheet