Denlok Express Rises To The Challenge

11 May 2021Allen Watson Ltd who provide trenchless installation services to groundwork contractors and building firms across the UK, were the contractors for the recent foul sewer installation project at a Redrow Housing Development in Kent.

The project challenge was to install a 225mm no dig drainage foul sewer system under Sutton Road in Maidstone, Kent.

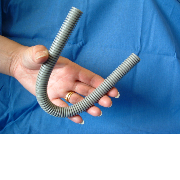

The solution was achieved by using Naylor’s DN225 Denlok clay jacking pipe, installed using an AWL GAB.85v guided auger bore machine with optical electronic navigation.

Naylor Denlok is a specially developed vitrified clay pipe system, available ex stock, to meet the requirements of pipe installation by trenchless construction methods, such as:

- Microtunnelling

- Guided auger boring

- Pipe bursting

- Pipe eating

- Slip lining

Simon Marsh, the project manager at Allen Watson, commented “There was extremely limited site space at the project and AWL were supported by the Naylor Drainage new lead time protocol of direct to site delivery within 5 working days. This facilitated the delivery of pipes for each individual drive, keeping the site footprint to a minimum"