ND Precision Products

ND Precision Products are one of the UK’s leading mould and press toolmakers. We are precision toolmakers offering extensive experience in plastic injection mould making, press tools and laser weld tool repairs.

Our established, long retained and highly experienced workforce can offer high priority turnaround times together with a professional and highly competitive precision toolmaking service. ND Precision Products have matched the vast experience built up since its foundation in 1973, with the latest engineering equipment and computer aided design facilities.

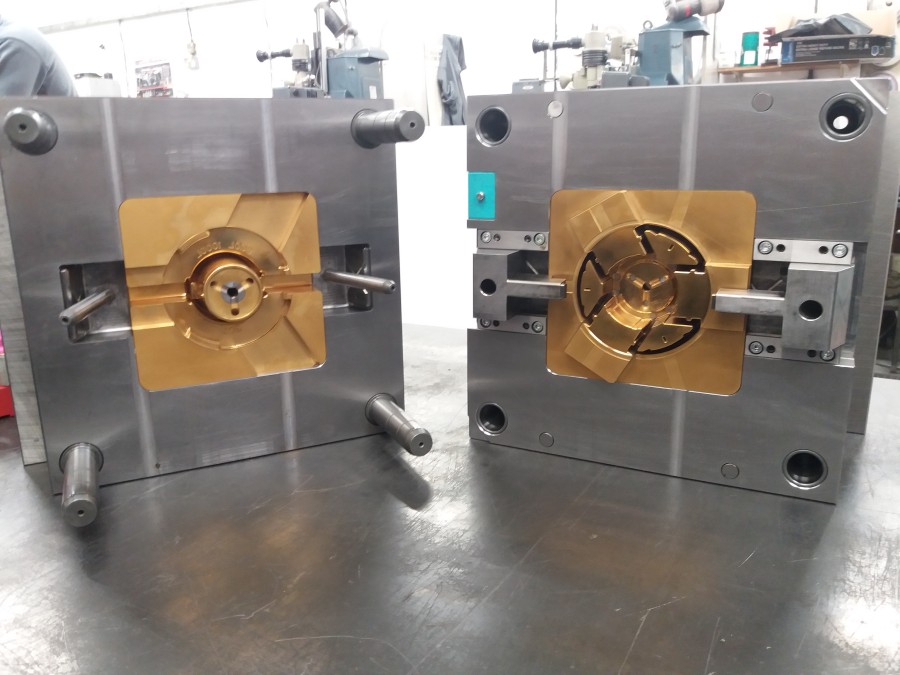

Mould Tools

Our service can be comprehensive from design through prototyping, pre production runs & evaluation, to managing production from a high capacity tool we have manufactured or whatever areas a client needs to ensure the desired result is achieved. Cassette QCO tooling – compression tools, thermo-set mould tools for Diesel Injection Systems. We manufacture an extensive range of orders for the Orthopaedic Industry, including tooling for manufacturing knee joints.

• DESIGN AND MANUFACTURE

• EJECTION MOULDS

• THERMOSET MOULDS

• OVERMOULD TOOLS

• COMPRESSION MOULDS

• MICRO MOULDING – BABYPLAST

• MOULD REPAIR

• MOULD SPARES

• PROTOTYPE MOULDS

• ELECTRODE DESIGN AND MANUFACTURE

• CONFORMAL COOLING

• QCO (Quick Change) Moulds

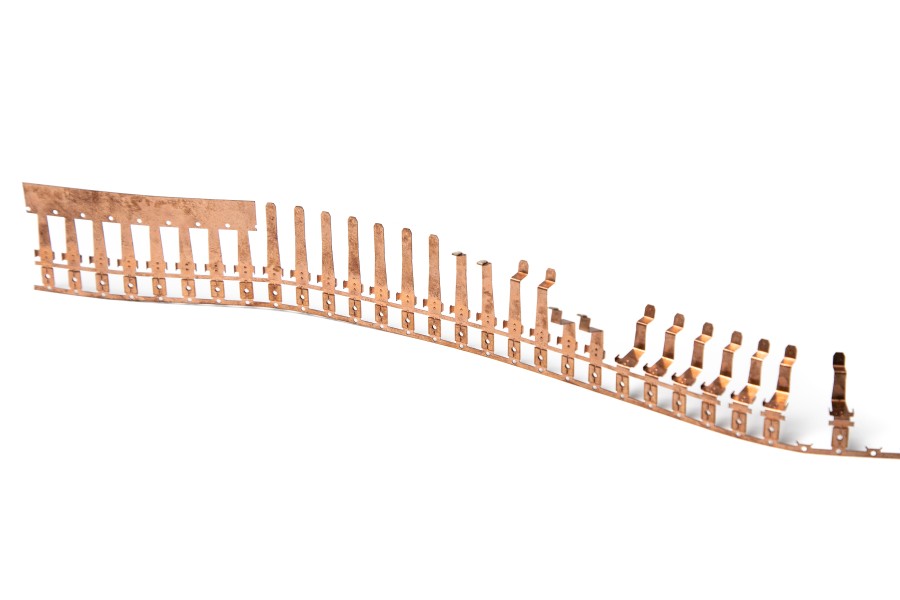

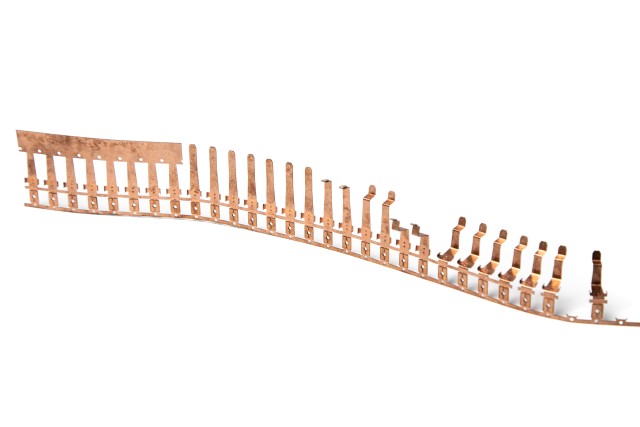

Press Tool Design & Manufacture

We are able to design and manufacture all types of Press Tooling from single stage operation to multi stage progression. Prototype tooling, 3D pin bending tools, use very high quality steels and quality carbides.

The following is within our capabilities:

• DESIGN AND MANUFACTURE

• PROGRESSION TOOLS

• PROTOTYPE TOOLS

• 3D PIN BENDING

• SPARE TOOLING

• CARBIDE TOOLS

Our press tool capabilities include bespoke services to your needs- as well as large scale or one-offs at any stage of development. Our extensive experience in the design of these tools, as well as our practical build experience we aim to provide you with your requirements in as short time as possible without loss to the high quality you come to expect from us.

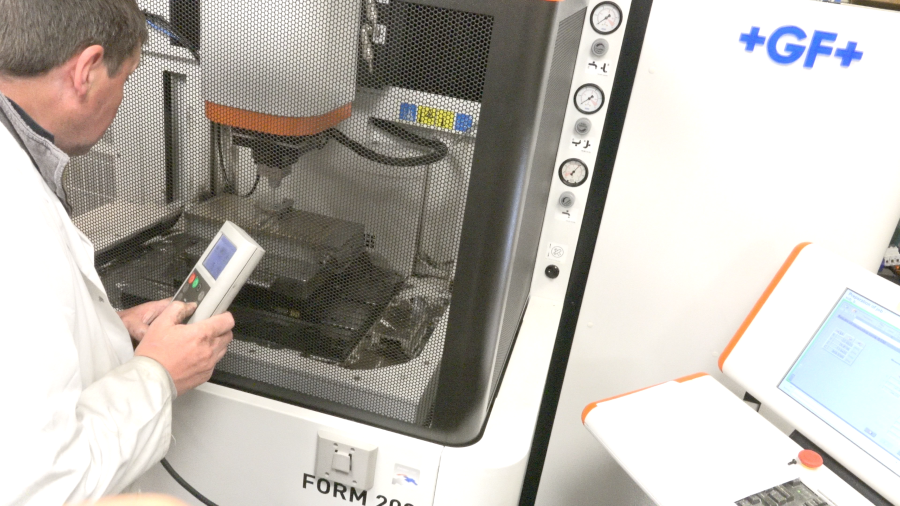

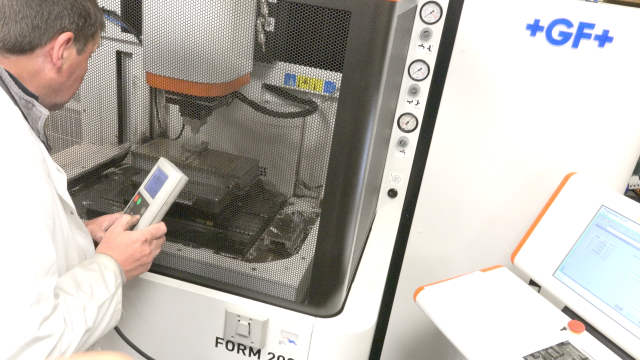

EDM / Spark Erosion

Over the years we have invested in our EDM equipment and have a GF Machining Solutions FORM 200 with System 3R Workpartner 1+ Robot. This has an 80-station electrode holding and an 8-station workpiece automation, allowing us to run spark erosion during unattended hours.

Supporting this machine, we also have a GF Machining Solutions FORM 20 and 2 Charmilles E110’s.

Using spark erosion, we can achieve surface finish to 0 VDI, providing a high quality, precise finish to your tooling that is otherwise very difficult to achieve with milling.

Laser Welding

ND Precision Products offer laser welding services for the modification and repair of damaged or worn tooling. Work-pieces of up 350kg can be processed quickly and precisely on 3 axes (x, y, z) and rotationally. The high quality weld and stable process ensures that the repair or modification does not affect the properties of the tooling material.

All ferrous material can be welded as we can make our own welding rods from your certified material.

3D Laser Scanning

Our recent purchase in December 2019 of a FARO 3D Laser Scanning Arm with 8-Axis allows us to quickly scan your product or tooling and compare the results with the CAD model; this lets us easily see areas of under or oversize.

The arm can also be used to reverse engineer your parts or tooling to create the 3D model allowing more accurate replicas to be made.

Precision Machining

At NDPP we specialise in precision machining – CNC Milling & CNC Turning – and precision machined parts; taking your products and ideas right from Prototyping, through Production to packaging across all materials from Aluminium and Stainless Steel to Titanium and Plastics. Full support is available including design and input in to cost effective precision machining.

To note,we supply OEM replacement parts, with a very quick turnaround, for the pharmaceutical industry.

- TURNING OIL & GAS

- VERTEX WEDM

- CASTING MACHINING

- WIRE EDM

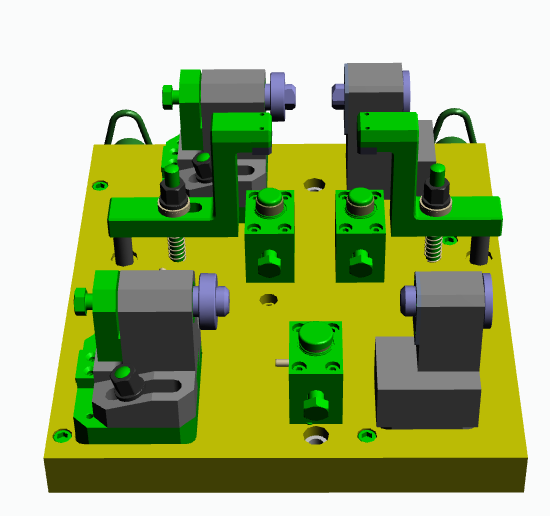

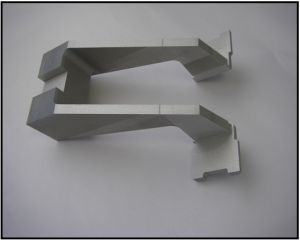

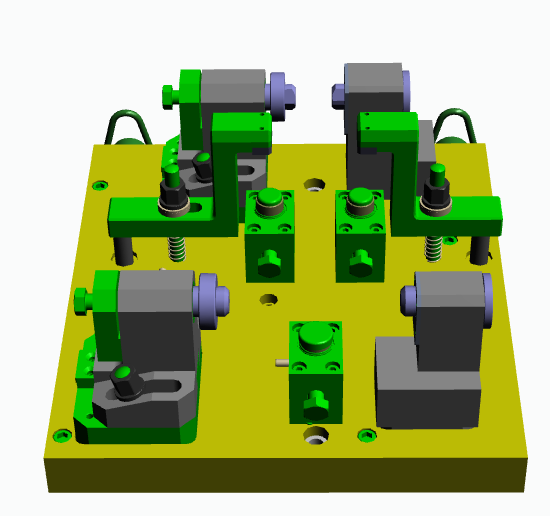

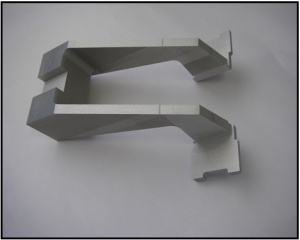

Jigs & Fixtures

Our tool-making and jig and fixture experience is built up from many years of manufacture for customers across the UK, together with our attention to detail, means that you can rely on us for high quality precision equipment and help with prototype development to fit your needs. We design and build jigs and fixtures to help with the machining, production or measurement of our customers products including 6 point location fixtures for accuracy and repeatability. Our customers like us because our skilled team have a genuine interest and take pride in their high quality precision work. We quote and win orders because we’re good at difficult and detailed assemblies, and our customers trust our ability to deliver on time and on budget.

- 3D PIN BENDING

- 6 POINT LOCATION

- CUT OFF FIXTURES

- EDM FIXTURES