PPSL (Precision Processing Services Ltd)

Precision Process Services Limited (PPSL) are the thermo-chemical cleaning specialists offering a comprehensive range of controlled cleaning processes for a variety of industrial equipment.

Our goal is to extend the life of customer parts to save money, increase equipment efficiency and protect the environment by reducing the scrapping of contaminated parts. Services we currently provide include:

-

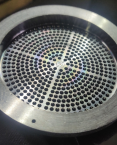

Metal Filter Cleaning & Testing Service

-

Ceramic Filter Cleaning & Testing

-

Pump Cleaning Service

-

Valve Cleaning Service

-

Gears and Bearing Cleaning Service

-

Heat Exchange Equipment Cleaning Service

-

Oxidation and Rust Removal

-

Extrusion Equipment Cleaning Service

-

Mixing Equipment Cleaning Service

-

Pipework and Pipe Fittings Restoration

Our technology

Here at PPSL we undertake research to always have the latest in cleaning technology and chemistry so to expand our cleaning services. We like a challenge – if you have a part needing cleaned or refurbished don’t hesitate in getting in contact.

Our current range of Technologies includes:

-

Chemical Solvent Cleaning

-

Thermo-Chemical Cleaning

-

Molten Salt Cleaning

-

Pyrolysis Cleaning

-

Flow and Bubble Point Integrity Testing

Research and Development is paramount at PPSL and our technologies are always improving and expanding.

Our customers

PPSL offers a range of cleaning and testing services for all kinds of industry. We have a diverse range of customers for our specialist services in the following industries:

-

Chemicals Processing and Manufacturing Industry

-

Oil and Gas Production and Processing Industry

-

Petrochemical Processing and Manufacturing Industry

-

Rubber and Plastics Manufacturing Industry

-

Polymer Processing Industry

-

Utility and Power Generation Industry

-

Automotive, Marine, Aerospace and Defence Industry

-

Pharmaceutical Manufacturing

-

Food and Beverage Processing

-

Medical Device Manufacturing

-

Printing and Packaging Industry

-

Agricultural Industry

-

General Engineering Industry

-

Electronics and Microelectronics Industry

-

Filter Manufacturing

Alongside our core business our experts provide diagnostic and analytical advice on how to improve your process or prevent fouling occuring in the future.

Filter products and services

-

Molten Salt Cleaning

Molten Salt Cleaning provides a deep penetration cleaning of the parts and is especially useful for cleaning metallic filter elements. Our Molten Salt can treat even the finest micron rated mesh to provide the most complete clean. The parts are placed in a bath of specially formulated salts and heated to the appropriate temperature under carefully controlled conditions. We will adapt our process to the specific conditions to suit the removal of the specified contaminate and thermal limits of the part to provide the most thorough clean and highest level of protection of your equipment. You can ask our experts whether your part is appropriate for Molten Salt, we’d be happy to answer any questions you have.

For further information visit our website www.ppsl-precision.com

Or if you have any questions please call on 028 7186 1600

-

Oxygen equipment cleaning

We offer a customised chemical refurbishment of fouled industrial process equipment which is based on the customers contamination and the materials of construction of the equipment. Our on site technical team designs each process taking into account the contamination, equipment and the customers requirements to provide the optimum clean. Along side this core business we offer process engineering solutions which look at our customers processes and advise on modifications for improvement. For more information about Oxygen equipment cleaning please either visit our web site at www.ppsl-precision.com or call us on 028 7186 0001 for helpful and friendly advice.

-

Part and Component Cleaning

New sectors provide new challenges, and this has required research and development into alternative cleaning processes and testing methods. Our processes have expanded across the years to account for other items of equipment such as pumps, valves, extrusion equipment, heat exchange equipment, etc. PPSL use a range of procedures to undertake the cleaning of various industrial parts and components. Each overall process involves a series of process steps which build together to enable the successful refurbishment of the parts. We are a tailor-made service so if you have any issues with fouling, blockage or dirty equipment please contact us so we can arrange a solution.

For further information visit our website www.ppsl-precision.com

Or if you have any questions please call on 028 7186 1600

-

Power Generation and Utility Process Equipment Services

The Power Generation and Utility industry utilize PPSL to service equipment often fouled with foreign matter difficult to remove onsite. Equipment is sent to PPSL and serviced with our thermo-chemical operation to clean contamination and oxidation without attacking the part. This requires a high level of control but has benefits economic, efficiency and environmentally for your company by extended the life of your parts and system thus reducing the need to replace parts as often. If you are in the Power Generation Industry/Utilities Industry and are concerned about equipment fouling or not lasting as long as you would expect then please contact PPSL to find a solution.

For further information visit our website www.ppsl-precision.com

Or if you have any questions please call on 028 7186 1600

-

Process Plant Equipment Cleaning

PPSL are internationally recognized for our chemical cleaning of plant and process equipment. We will design a tailor-made process for your part and your needs specifically so to provide the most efficient clean and removal of contaminant without damage to the part. Our processes are comprised of a series of steps to provide the highest standard of refurbishment for your parts. The chemistry used is adapted to protect the materials of construction but provide a thorough removal of contamination. Our process is controlled by experts in chemistry with years of industrial cleaning experience which will guarantee the safety of your parts.

For further information visit our website www.ppsl-precision.com

Or if you have any questions please call on 028 7186 1600

-

Pump Cleaning

PPSL provide a high standard of clean and servicing to Pumps used on-line that have become fouled with contaminate or oxidation. We receive Pumps across various industries requiring unique processing, here at PPSL we are a customer friendly operation and will accommodate any issues you may have with your Pump online. We will design a tailor-made cleaning process to ensure your Pump returns to optimum operation level depending on the type of material and contamination; this is to ensure the highest standard of clean and protection of part integrity.

For further information visit our website www.ppsl-precision.com

Or if you have any questions please call on 028 7186 1600

-

Pyrolysis Cleaning Services

Here at PPSL we have unique opportunity for Pyrolysis Cleaning as we have ovens of different shape and sizes to suit your part. Pyrolysis Cleaning is especially useful for the removal of modern speciality chemicals and high temperature resistant polymers. We can provide a high temperature in a low oxygen environment causing the decomposition of even the highest thermal resistant polymers to ash without damaging the part. PPSL has an advantage over other pyrolysis processes as we can enhance the final clean of the equipment with our customised chemical cleaning processes.

For further information visit our website www.ppsl-precision.com

Or if you have any questions please call on 028 7186 1600

-

Rubber and Polymer Process Industrial Equipment Services

Rubber and Polymer Process Equipment often become blocked, fouled or blinded by the resolidifying of material on system parts. At PPSL we can remove even the highest temperature resistant polymers from pumps, valves, filters and pipework. Our cleaning services specialize in removing polymer from process equipment so your part will receive the deepest clean and best treatment. If you are in the Extrusion, Rubber or Polymer Industry please contact PPSL to ensure your equipment is performing up to standard. With years of experience working alongside this industry our experts can also offer diagnostic advice on your process.

For further information visit our website www.ppsl-precision.com

Or if you have any questions please call on 028 7186 1600

-

Solvent Cleaning Service

Our solvent treatment of parts involves specially formulated chemistry to provide bulk removal of contaminant. Our commonly used solvents are extremely effective in removing polymers, oils and resins from equipment providing a heavy duty clean without damage to the part. Our site has speciality equipment for the operation of solvent cleaning at high temperature and pressure. Solvent cleaning can used alongside other cleaning processes here at PPSL.

For further information visit our website www.ppsl-precision.com

Or if you have any questions please call on 028 7186 1600

-

Spinneret Cleaning

PPSL use a range of procedures to undertake the cleaning of spinnerets and other extrusion equipment. Each overall process involves a series of process steps which build together to enable the successful refurbishment of the parts. Our Thermo-Chemical cleaning service provides the deepest clean out of contamination without attacking the Spinneret. We can service even the toughest to remove contamination and can service your part for oxidation or rust if required. If your process uses Spinnerets please contact PPSL and we can service them for the extension of their operating life.

For further information visit our website www.ppsl-precision.com

Or if you have any questions please call on 028 7186 1600