RGH Rubber and Plastics Ltd

RGH has been established for over 35 years and specialises in the conversion of technical materials for a range of industries including automotive, point of sale, electrical and medical.

RGH manufacture all components in-house with state of the art technology which enables a quick delivery time. High quality standards ensures that the highest expectations are constantly met by a team of technical and highly driven people.

Specialists in sealing, dampening, bonding, insulating, cushioning, silencing, gliding and packaging.

RGH are converters of technical foams such as neoprene, EPDM, polyethylene, silicone and PVC along with specialist materials such as felts, fabrics, rubber, plastics and adhesive tapes.

RGH are Preferred Converters of 3M materials and convert the full range of thin bonding and thick bonding tapes including acrylic foam tapes, VHB's, industrial adhesives as well as medical grade adhesives.

Call and speak with one of the technical team or send and email. RGH will strive to find a suitable solution to your requirements.

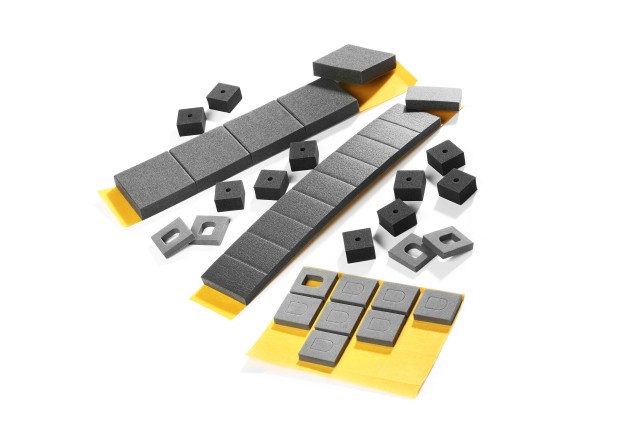

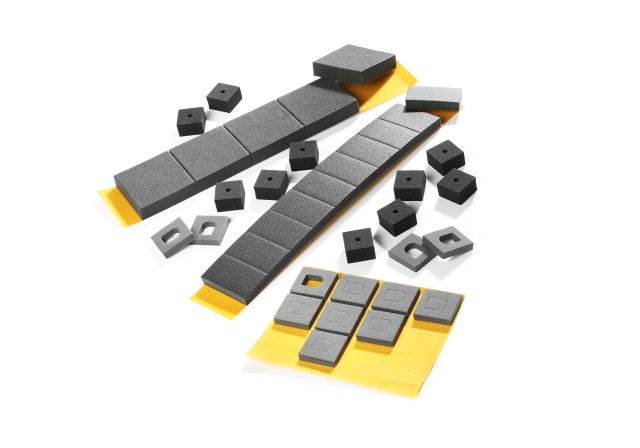

Polyethylene Foam

Polyethylene Foam

Polyethylene (PE) foam is a closed cell foam available in a wide range of densities. PE foam is generally lightweight compared to other closed cell foams but also surprisingly strong. It has good chemical resistance and its aging properties means that it will not deteriorate and go brittle over time. Polyethylene has excellent water resistance and due to its closed cell nature it has excellent sealing properties and is also commonly used for buoyancy aids. It is a cost-effective foam and can be easily shaped, cut and routed which makes it ideal for most packaging applications including case inserts.

Key Properties

Closed Cell

Cost Effective

Large range of different densities and hardness’s

Multiple colours available

Good temperature resistance

Good water resistance

Good ageing resistance - Will not go brittle over time

Excellent sealing properties

Potential Applications

Buoyancy aids

Spacer blocks/void fillers

Case Inserts and packing pieces

Medical pads

Floor underlay

Protection Pads

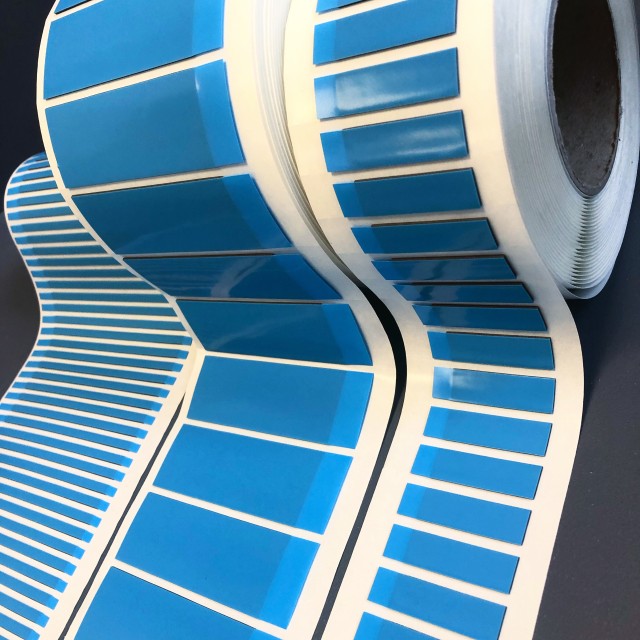

3M VHB and adhesive tapes.

3M™ VHB™ Tapes

3M™ VHB™ Tapes are a family of double-sided foam tapes made from high performance acrylic adhesives. These tapes can form bonds of exceptional strength and have greater durability and elasticity than conventional double-sided foam tapes. The VHB Tape range includes tapes with different core constructions and a variety of adhesives. All 3M VHB Tapes use closed cell technology and provide outstanding environmental resistance and durability. The superior performance of 3M VHB Tapes means they can often be used to replace mechanical fasteners for joining a wide range of materials.

For information about 3M Acrylic Foam Tapes for Automotive Applications please click here

Benefits of using 3M VHB

· No holes to drill, no riveting, no liquid adhesives to cure, no weld distortion, no clean up.

· Prevents corrosion by separating dissimilar metals.

· Is invisible and eliminates unsightly rivets, spot welds, screw-heads or nuts and bolts.

· Meets a wide range of holding requirements for tough applications involving glass, metals, woods, composites and many plastics.

· Damps vibration and reduces noise.

· Resists solvents and salt water. Seals and bonds even in extreme environments.

· Can compensate for thermal expansion and contraction of bonded parts.

· Distributes stress. Excellent for thin materials.

· Fast, clean and simple to apply. Reduces assembly costs.

Double Sided Foam Tape

Double sided Foam

RGH stock a range of double sided foam tapes ranging from 0.5mm to 3mm thick as standard. Rubber and acrylic adhesive systems are available with polyethylene, pvc and polyurethane carriers available. Different densities of foam are offered depending on whether the final application requires the foam to have good internal strength.

Double sided foam tapes are commonly used to adhere to uneven surfaces as the additional thickness allows them to compensate for irregular undulations. Whether you require a foam with good shear strength, good initial tack or a foam suitable for external conditions, RGH will have a product to suit your needs.

Black or white foams are standard and RGH specialise in converting this material in to many formats to help aid with application. When converting this material in to pads or strips an oversized liner can be added to the top surface to save time when applying it.

Felts and Fabrics

Felts and Fabrics

RGH stock a range of felts, viscose fibre, flock as well as resin bonded and woven materials ranging from 0.3mm to 5mm in thickness (as standard). These materials are commonly used as anti-rattle and anti-vibration pads within the automotive industry or can be used as decorative materials within many sectors.

Black and white felts are available as standard but other colours are also available upon request. Different adhesives can be laminated to each of these materials depending on the substrate that you are adhering to and RGH have the facilities to convert all materials in to the appropriate size to suit your requirements.

Available Formats

Logs

Slit Rolls

Pads

Strips

Discs

Bespoke Shapes

Potential Applications

Anti Rattle and anti vibration pads

Anti squeak components

Cable wrapping pads

Non-scratch bases

Decorative Finishes

Protection pads

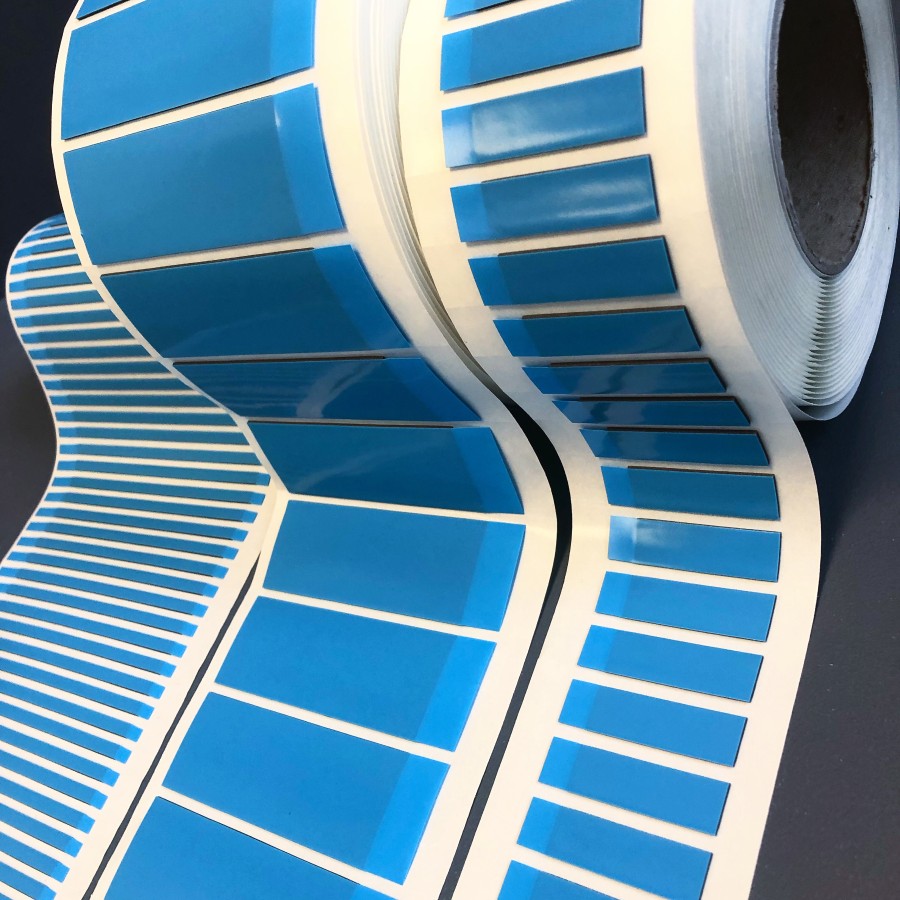

Double Sided Tapes

Double Sided Tapes and Thin bonding solutions

With both acrylic and rubber based adhesive systems available as transfer tape or with tissue, scrim, filmic or cloth carriers, RGH's range of double sided tapes are multi-purpose tapes used within a range of industries. Used in-house as adhesive on our foams and fabric products and popularly used for bonding, mounting and laminating of plastics, metal, wood, paper, ceramics and many other substrates.

As well as permanent adhesives, RGH also stock and convert resealable tapes, skin contact approved and peelable adhesive systems.

RGH work closely with our global supply partners which include 3M, Avery, ATP, Tesa, Lohmann and Scapa. This relationship enables us to have access to the finest double sided tapes available so no matter what industry or what substrate you are trying to bond, a suitable solution will be found.

We also welcome customers to to test their substrates in our in-house laboratory which will ensure that the correct adhesive is used to create a successful bond.

Formats available

Logs

Slit Rolls

Pads

Strips

Discs

Bespoke Shapes

Laminated components

Neoprene Foam

Closed cell Neoprene Foam

Neoprene (also known by its chemical name Chloroprene) is a black closed cell foam that is medium to high density. It has good tear and chemical resistance along with an ability to cope with a good range of temperatures. Neoprene is flexible and has good aging properties meaning that it will not deteriorate over time. Flame retardant and preferred to EPDM when oil and grease are present. Neoprene is seen as one of the best gasketing materials due to its durability and its recovery properties once under compression.

Neoprene that is grey in colour with UL94-HF1 classification is also available

Key Properties

Closed Cell

Good ageing resistance

Excellent sealing properties

Low compression set

Excellent oil and chemical resistance

Flame retardent

Potential Applications

Expansion joints

Water, dust and air seals

Lighting gaskets

Weather strips

Glazing seals

Anti vibration pads

Polyurethane Foam (PU Foam)

Open Cell Polyurethane Foam

Polyurethane (PU) foam has an open cell structure which makes it lightweight, flexible but also durable. Commonly used for cushioning applications but also has very good insulation properties that provide protection from heat and acoustics. Generally low in density has good recovery, good temperature resistance and flame retardancy. PU foam is easily compressed to make good dust seals, help with air filtration as well as assisting with the reduction of noise.

Key Properties

Open cell

Lightweight

Flexible

Easily compressible

Excellent acoustic absorber

Good thermal insulation

Potential Applications

Seat, head rest and armrest fillings

Sound absorption and vibration dampening

Carpet backing

HVAC noise reduction

Dust seals

Packaging and protection pieces

Foam Case Inserts

RGH design and manufacture customised foam case inserts from a wide range of foams to suit. The beauty of having a customised packing piece is that it will not only help to securely protect your product but it also helps to present them in a professional and stylish manner. Case inserts could ultimately save you money. By protecting your products properly you therefore reduce the chance of damage, customer complaints and returns.

RGH’s in-house CAD experts will make the design process as simple as possible and help you to create the perfect solution, first time. By using the latest in digital plotter technologies, foam inserts can be made from one solid piece of foam, rather than laminating multiple sheets of foam together.

RGH can mill foams to different depths giving you an extremely accurate and solid packing piece. This capability also significantly reduces production times

Prototype parts can be built prior to production to ensure that you are totally satisfied with your product

EPDM Sponge

Closed Cell EPDM sponge rubber

EPDM sponge is medium to high density, closed cell foam with good ageing, ozone and UV resistance. Its closed cell structure makes it impermeable to air, dust and water which makes it an ideal material for many sealing applications. Available in black and white with medium to high temperature resistance. It is a flexible and durable gasketing material which can also have adhesive applied to one or both sides.

Key Properties

Closed Cell

Good temperature resistance

Excellent ozone resistance

Good ageing resistance - Will not go brittle over time

Durable

Excellent sealing properties

Available Formats

Logs

Slit Rolls

Pads

Strips

Discs

Bespoke Shapes

Potential Applications

Trim, door and window Seals

Electrical and lighting gaskets

Weather strips and seals

Anti-vibration and NVH Solutions

Cushioning pads

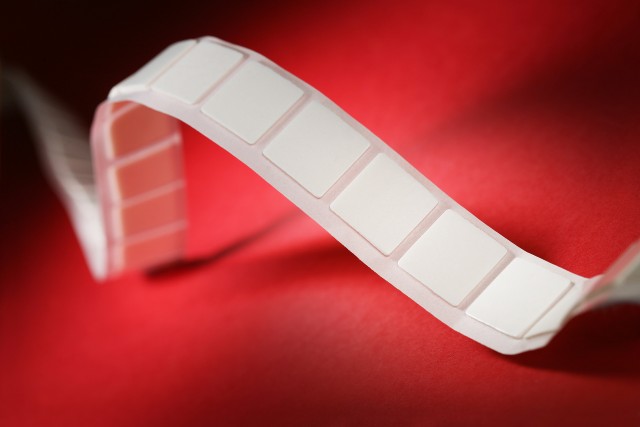

Hangtabs

RGH Manufacture every hangtab in-house giving you flexibility in terms of the thickness of plastic, the amount of adhesive and the format that you purchase your hangtabs.

The range of hangtabs can be produced in many formats including sheets, individually cut parts, booklets or most commonly rolls. RGH can produce as many parts on a roll as you require

Any size of hangtab is available subject to tooling

Should you need to automatically apply your hangtabs then RGH can manufacture your hangtabs on a clear filmic liner which prevents liners snapping and aids magic eye readers to see through the liner

All hangtabs are produced with the euroslots and waste areas removed to save you the time and inconvenience of having to remove them

RGH's coating systems allow for different coatweights of adhesive to be applied to suit your application and to cope with the weight of product that you wish to hang

Crystal clear adhesive is available upon request

Extensive manufacturing capabilities allow RGH to process materials ranging from 100 micron up to 600 micron depending on the product required

All hangtabs are manufactured using recycled plastic.

Shoddy Felt / Cotton Waste

Shoddy felt (also known as cotton waste felt) is a recycled material often used in the automotive industry for use in door panels, trunk liners and instrument control padding.

It is a low cost material which is mainly used for sound absorption and sound damping applications. It can be laminated and die cut to shape in order to fulfil your requirements.

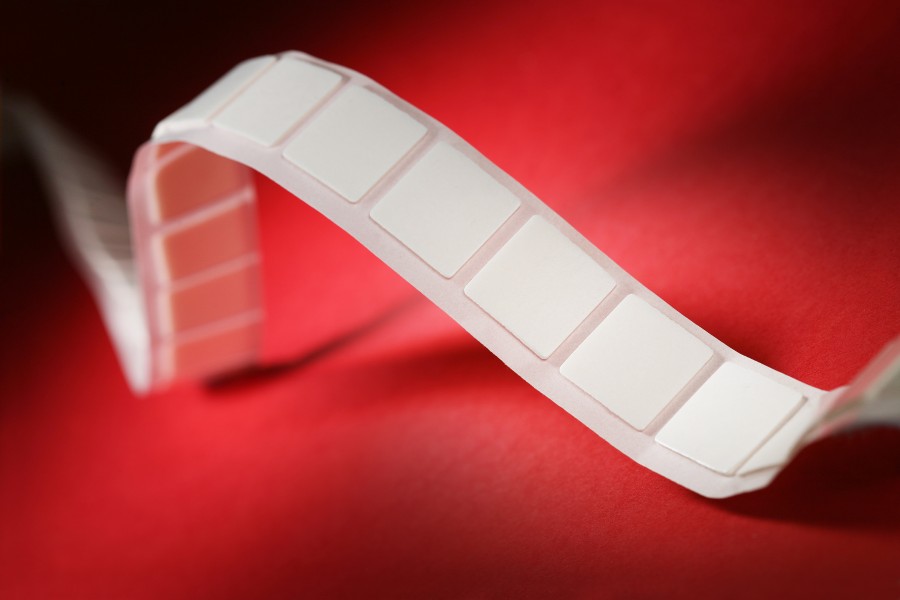

Double sided foam pads

RGH manufacture a wide range of double sided foam pads using high quality polyethylene foam with either rubber resin or acrylic adhesives.

Ranging from 1mm thick to 25mm thick RGH can produce pads in almost any shape or size. Traditionally used for bonding paper, card, plastics and metal within many industries such as display, signage and point of sale.

Solid Rubber

RGH’s extensive range of solid rubber is available in neoprene (chloroprene), natural, butyl, nitrile, EPDM, Viton and silicone.

Our black commercial grade rubbers offer an affordable solution for most gasketing requirements but should you have a more specialist requirement then we will have the product that you require. Our in-house conversion facilities enable us to offer rubber in any converted format including rolls, strips, washers and bespoke die cut shapes. A self-adhesive backing can be applied should you need it.

All grades of rubber are available in a variety of thicknesses and hardnesses and materials are also available to a wide range of British Standards including BS2751 and BS2752. Flame retardent and high temperature rubber are also available.

Potential Applications

Anti vibration pads

Shock Absorber gaskets

Washers

Spacer pads

Lighting gaskets

Oven/high temperature gaskets

Component seals

UHMW (Ultra high molecular weight) Tape

RGH's UHMW tape not only protects surfaces but it also creates a slipping effect to allow contact between two substrates without wear.

UHMW tape reduces squeaks between two materials but also promotes movement between two moving parts whilst also reducing rattles and other noises.

Design and Prototype Department

RGH's CAD and design team will help you devise the perfect solution for your application. Whether you need to eliminate unwanted noise, secure a product in place, create a spacer gasket or simply bond two products together, RGH's design team will work around the clock to help you design a component to fulfil your needs. Once the component is designed the design will be passed to the prototyping department in order to produce a rapid prototype.

This enables you to see and apply a finished component before moving on to full production, also eliminating the need to buy tooling just to see whether the design and specification of the material is correct. Modifications can then be made until the perfect solution is created.