RGH Rubber and Plastics Ltd

RGH has been established for over 35 years and specialises in the conversion of technical materials for a range of industries including automotive, point of sale, electrical and medical.

RGH manufacture all components in-house with state of the art technology which enables a quick delivery time. High quality standards ensures that the highest expectations are constantly met by a team of technical and highly driven people.

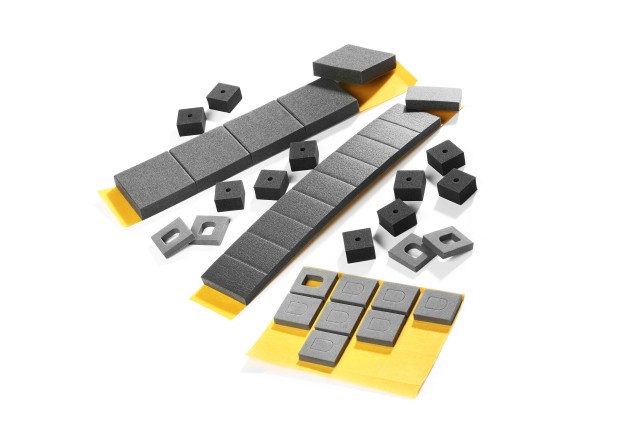

Specialists in sealing, dampening, bonding, insulating, cushioning, silencing, gliding and packaging.

RGH are converters of technical foams such as neoprene, EPDM, polyethylene, silicone and PVC along with specialist materials such as felts, fabrics, rubber, plastics and adhesive tapes.

RGH are Preferred Converters of 3M materials and convert the full range of thin bonding and thick bonding tapes including acrylic foam tapes, VHB's, industrial adhesives as well as medical grade adhesives.

Call and speak with one of the technical team or send and email. RGH will strive to find a suitable solution to your requirements.

-

RGH opens fourth manufacturing facility

8 September 2022RGH are proud to announce the opening of their fourth facility in Great Dunmow, Essex. RGH plan to continue to build its reputation as one of the leading material converters in the UK and this investment will increase manufacturing capacity to help cope with recent growth whilst also preparing them for future demands. It has also allowed RGH to invest in the latest slitting and die cutting machinery which in turn has lead to the expansion of its workforce.

12 months of hard work have been spent redeveloping the offices and manufacturing facility to make it a clean, modern and fully airconditioned environment for people to work in. Opening this new unit will signal the next chapter in RGH’s history of innovation and manufacturing excellence

-

RGH invest in design and prototype departments

17 January 2019RGH have invested in the latest digital plotter technology enabling them to produce rapid prototypes without the need of costly tooling.

RGH also have a team of CAD designers who can help you create your component before using this template to cut your product out of foam, felt, rubber, plastic or whichever material suits your requirements. This enables you to see and apply a finished component before moving on to full production, also eliminating the need to buy tooling just to see whether the design and specification of the material is correct. Modifications can then be made until the perfect solution is created.