Rico Industrial Services Ltd

The UK”s leading tube and pipe maintenance company. With over 25 years experience in servicing heat exchangers, condensers, and cooler tubes using our patented mechanical cleaning process. We are providers of tube cleaning equipment, tubesheet coatings and tube plugs.

We are also the UK distributor for Rydlyme and Rydlyme Marine – the worlds leading biodegradable de–scaler. Totally safe to use, environmentally friendly, and dissolves water scale quickly and efficiently.

Tube Cleaning

At RICO we offer a variety of different services to clean heat exchanger tubes. We have many years of experience in resolving tube fouling issues. These services include the Mechanical Scraper System, High Pressure Water Jetting, the Air Mate TM Pellet Launcher System, the ARW Tube Cleaning Machine, and Rydlyme - the world's leading biodegradable descaler. All these processes with the exception of High Pressure Water Jetting and the Mechanical Scraper System are available for use by the client and can be purchased direct from RICO.

We can clean:

- Heat Exchangers

- Coolers

- Chillers

- Evaporators

- Condensers

- High Pressure Heaters

- Low Pressure Heaters

- Absorption Units

- Boilers

Please browse our departments for more information on our products.

Leak Searching

Using foam to search for on-line leaks is a relatively simple but effective method to quickly find condenser tube leaks.

By using a specific foaming agent that is created by the foam generator the tube plates are covered completely with the foam, Any tubes where the foam is sucked into the tube signifies that a leak is present. These leaking tubes can be verified using a variety of instrumentation and plugged.

Off-Line Leaks using Pneumatic Leak Detector Guns

This system uses pneumatic detector guns that are inserted into either end of a tube. When activated these guns fill the tube with compressed air. If a leak is present the tube will depressurise and this change in pressure is detected by the guns which in turn signal a leak. As an alternative method, a Vacuum Leak Detector kit can be used where a vacuum is created to find the leak.

Tube Inspection Services

NDT inspection services for tube bundles to include heat exchangers, condensers, oil coolers, air conditioning units. .

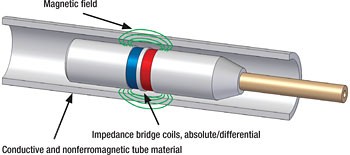

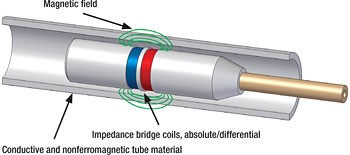

Eddy current is based on the principle of measuring changes in the impedance of an electromagnetic coil as it is scanned over a surface of conductive material.

Using eddy current inspection techniques you can quickly detect tube corrosion, pits, wall loss and cracks.

Coating Services

In association with our partner GMA S.R.L (Italy) we can offer specifically manufactured anti-corrosion coatings designed for the prevention and elimination of corrosion and erosion found in tube-sheets and tubes of heat exchangers and condensers.

GMA uses it own patented technology to produce and apply coatings for restoring and strengthening tube-sheets, water-boxes, tube inlets and the full length of the tube internals back to their original condition.

Descaling

RYDLYME is specifically designed to dissolve the toughest water scale, lime, mud, and rust deposits from virtually any piece of water based equipment.

This powerful, yet totally safe, liquid is non-toxic, non-flammable, non-hazardous, non-corrosive and biodegradable; so RYDLYME will not harm your personnel, equipment or our environment!

Water scale deposits are a significant cause of heat transfer loss, along with the subsequent increase in energy costs. In fact, even a thin layer of scale (1mm) can cause a 30% increase in the cost to operate that piece of equipment.

Keeping the cooling passages free of mineral deposits significantly improves efficiency, conserves energy, extends the useful life of the equipment, and saves your plant time & money.

RYDLYME is utilised by circulating this revolutionary solution throughout the fouled water passages via a simple pump. There is no need for labour intensive dismantling of the equipment. Some equipment may be cleaned while it is in operation without the necessity of a shutdown.

RYDLYME is very fast too. Most cleaning applications are completed within a 4 hour period! From a small lube oil cooler to an entire plant cooling system, RYDLYME will effectively dissolve hard water deposits safely, quickly, and economically.

Condenser & Heat Exchanger Tube Cleaning

AT RICO WE OFFER A VARIETY OF DIFFERENT SERVICES TO CLEAN CONDENSER & HEAT EXCHANGER TUBES

We have many years of experience in resolving tube fouling issues. These services include the Mechanical Scraper System, High Pressure Water Jetting, the Air-Mate TM Pellet Launcher System, the ARW Tube Cleaning Machine, and Rydlyme - the world's leading biodegradable descaler. All the equipment for these processes with the exception of High Pressure Water Jetting and the Mechanical Scraper System are available for use by the client and can be purchased direct from RICO.

Mechanical Scraper System

The Ultimate Tube Cleaning Solution For Condensers, Heat Exchangers, Coolers, And More...

The Mechanical Scraper System uses our unique booster pump to generate water pressure to propel specially designed cleaners down the tubes, cleaning as they go.

The cleaners are loaded in batches and it is clearly identifiable to see which tubes are to be cleaned. The operator then fits the gun into each tube and pulls the trigger to release the low pressure, high volume water, to power the cleaner through each tube. A gauge on the water gun indicates when the cleaner has exited the cleaned tube. The operator continues this process until all the tubes have been cleaned.

The cleaners come in a variety of designs, materials, sizes and gauges to suite the cleaning needs of your condenser tubes.

Tube Plugs

The Rico "Plug-It" Tube Plug Offers A New And Inexpensive Way To Seal Leaking Heat Exchanger Tubes Safely, And With The Minimum Of Fuss.

The two components that make up the tube plug (main body and a nickel plated expansion pin) are all produced from advanced polymer materials. This combination of materials together with the unique design of the product results in the ability to withstand temperatures of up to 150° C and working pressures of up to 130 psi.

HOW DOES IT WORK?

The external dimensions of the plug body are designed to be an interference fit in the tube end. The internal profile incorporates two main attributes:

- The domed internal face is designed to displace the stresses resulting from internal tube pressure toward the plug periphery, thus increasing radial expansion into the tube bore and counteracting a force which could dislodge the plug from its position.

- The tapered internal bore of the plug, combined with the parallel diameter of the expansion pin, results in a flexible and consistent circumferential expansion into the tube bore.

This unique design ensures that any increase in pressure within the channel resulting from the operation of the heat exchanger can only drive the expansion pin further in, once again resulting in an improved seal with the tube bore. The grade of polymer used is suitable for a wide range of mediums including fresh water, seawater, oil, Freon and many other chemicals and solvents.

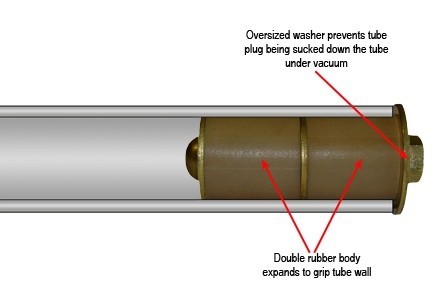

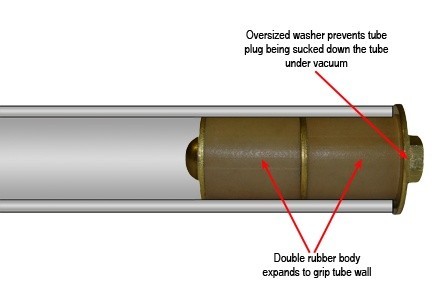

Double Rubber Tube Plug

Manufactured To Fit Condenser & Heat Exchanger Tubes From 5/8" To 1 1/4" ID. The Plug Is Designed To Withstand A Range Of Temperature, Vibrations And Pressures Up To 150 Psi.

It features an over-sized washer that fits over the tube opening and a double rubber body that adjusts to fit the tube wall giving a tight fit. Suitable to fit tubes that have a larger tube ID, where the tube has been expanded into the tube-sheet, than the rest of the tube.

Available in brass, stainless steel, titanium, bronze and monel.

Air Mate Tube Cleaning Equipment

The AIR-MATE pellet launcher uses compressed air to fire a foam pellet through hose, pipe or tube clearing soft deposits and loose debris as it travels through. Pellets used in the AIR-MATE system will travel through 90 degree angles, "T" joints, coils, "U" tubes, bore and straight-through valves.

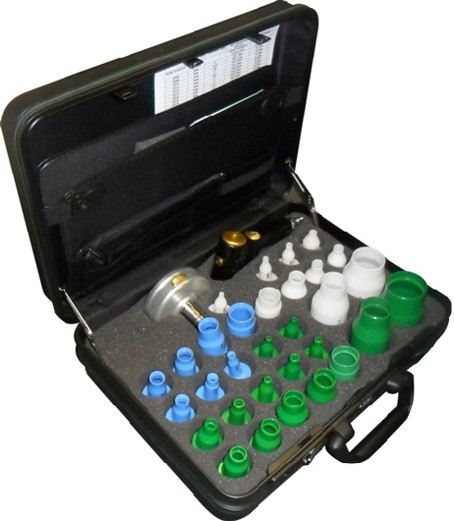

Air Mate Pellet Launcher Kits

The pellet Launcher is designed to operate at 80 – 110 psi and should be connected by a 3/8 (10mm) ID air line to an air source NOT exceeding 150 psi.

The Full Kit contains:

1 x Pellet Launcher complete with 50mm Head

1 x Adapter Ring sized to suit 13/64 (5mm) to 1 ¼ (32mm) nozzles

31 x Nozzles (5mm - 50mm)

1 x Carry Case

1 x User Guide

Foam projectiles are available to order seperately.

Replacement Nozzles are available to order seperately.

Air-Mate Pellet Launcher Crimp Kit

The Crimp Kit is specifically for use with hose, tube and pipe from 5mm - 50mm.The Hose Nozzle fits over the tube, hose or pipe to be cleaned.

The pellet Launcher is designed to operate at 80 – 110 psi and should be connected by a 3/8 (10mm) ID air line to an air source NOT exceeding 150 psi.

The Crimp Kit contains:

1 x Pellet Launcher complete with removable 50mm Head

1 x Adapter Ring sized to suit 13/64 (5mm) to 1 ¼ (32mm) nozzles

10 x Hose Nozzles (5mm - 50mm)

1 x Carry Case

1 x User Guide

Foam projectiles and replacement nozzles are available to order separately.

Standard Pellets

Standard Pellets are designed for removal of debris from all hose, tube or pipe, without fittings.The projectile is manufactured from foam and should be approx 15 - 20% larger than the i.d. of the hose, tube or pipe being cleaned.

Sizes

7mm, 8mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm & 22mm (bag quantity 300)

24mm & 26mm (bag quantity 200)

28mm, 30mm, 33mm, 35mm & 40mm (bag quantity 50)

45mm & 50mm (bag quantity 40)

55mm & 60mm (bag quantity 30)

Please note there is a minimum total order value of £30 excl VAT & shipping

Abraasive Pellets

The Abrasive pellet is designed for use in tube or pipe where there is a build up of contamination, rust or mill scale. The projectile is manufactured from foam and should be approx 15 - 20% larger than the i.d. of the tube or pipe being cleaned.

Sizes

6mm, 7mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm & 22mm (bag quantity 300)

26mm (bag quantity 200)

33mm & 40mm (bag quantity 50)

50mm (bag quantity 40)

Please note there is a minimum total order value of £30 excl VAT & shipping