RSA Cutting Technologies Ltd

We supply sawing centres for single or multiple cuts, steel or stainless steel parts or non-ferrous metals. Our sawing centres are provided with short set-up times, easy operation, high precision and high economic efficiency. They can be smoothly integrated with all subsequent steps in processes such as deburring, chamfering, measuring, washing and stacking.

Filter products and services

-

Multiple cut

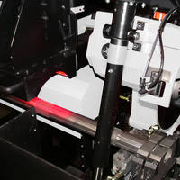

If you need very high output, then select our triple-cut saw RASACUT MXS. The sawing centre is designed for a tube diameter of 8mm to 20mm in triplecut and 6mm to 45mm in single-cut. These dimensions are often found in the automotive industry with special requirements on precision, surface quality and purity. Areas of application include fuel and brake lines or visible components in the interior such as head rest supports. Both the infeed of work pieces as well as transfer to subsequent processes are done using NC-axes that operate with a speed of up to 5m/s. Safe handling of work pieces before, during and after the cutting process guarantees tight tolerances and gentle handling of surfaces so that subsequent chrome plating goes smoothly. Important for automotive suppliers: The work pieces are individually processed and measured after cutting. This guarantees real 100%-control, conforming with the guidelines and standards of the OEMs. Do you need a single cut saw for small diameters? Then learn about the RASACUT XS!Request a Quote Supplied by RSA Cutting Technologies Ltd -

multiple cut saw

If you need very high output, then select our triple-cut saw RASACUT MXS. The sawing centre is designed for a tube diameter of 8mm to 20mm in triplecut and 6mm to 45mm in single-cut. These dimensions are often found in the automotive industry with special requirements on precision, surface quality and purity. Areas of application include fuel and brake lines or visible components in the interior such as head rest supports. Both the infeed of work pieces as well as transfer to subsequent processes are done using NC-axes that operate with a speed of up to 5m/s. Safe handling of work pieces before, during and after the cutting process guarantees tight tolerances and gentle handling of surfaces so that subsequent chrome plating goes smoothly. Important for automotive suppliers: The work pieces are individually processed and measured after cutting. This guarantees real 100%-control, conforming with the guidelines and standards of the OEMs.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Wire Brushes

Through intensive research and development RSA further developed conventional technical brushes into intelligent industrial brushes. To this end, special types of wire were developed for various applications. This means for our customers excellent processing results in constant quality and a longer working life . The result: low costs per processed workpiece. The benefits: We control the complete manufacturing process and produce quality tools with the following features: * Quality wires with long working life * Very short processing times * True running throughout the lifetime of the brush * Trimming of the brushes according to specific requirements * High wire density * Secure fitting for high peripheral speeds * Continuous cutting performance for reproducible qualityRequest a Quote Supplied by RSA Cutting Technologies Ltd