RSA Cutting Technologies Ltd

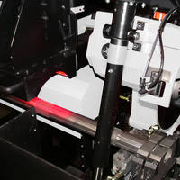

We supply sawing centres for single or multiple cuts, steel or stainless steel parts or non-ferrous metals. Our sawing centres are provided with short set-up times, easy operation, high precision and high economic efficiency. They can be smoothly integrated with all subsequent steps in processes such as deburring, chamfering, measuring, washing and stacking.

Filter products and services

-

Dry Cut Metal Circular Saw

Here at RSA Cutting Systems Ltd, we manufacture and supply Dry Cut Metal Circular Saws, please contact us for more information.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Dry Metal Saw

Here at RSA Cutting Systems Ltd, we manufacture and supply Dry Metal Saws, please contact us for more information.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Edge rounding

Edge rounding is a special procedure for surface treatment of work pieces. The work pieces are rounded by a special brushing procedure. RSA developed the RASAMAX MONO and DUO for this purpose, universally usable machines for sheet metal made of steel, stainless steel and non-ferrous metals. They are ideal for single pieces and small series of sheet metals with contours and notches and straight sheet edges.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Feeding

Bundle loader The bundle loader feeds complete tube bundles to the saw. In this way the saw can operate for a longer period without a manual feeding of the base lengths. All contact surfaces to the workpiece are of plastic or Vulkollan so that the surfaces are protected. It is possible to set the bundle loader to other diameters within a few seconds. Inclined placing magazine Inclined placing magazines are particularly suitable for large tube diameters or solid bars up to 170 mm. They offer an easy feeding of single bars via crane for small batches and can be expanded with a preceding belt trough. In this way even complete bundles can be processed. Loading table A loading table is the space-saving, simple and economical solution for the feeding of single bars for small batches. The bars are easily fed manually, fork lift or crane are not required. Base lengths up to 6,200 mm can be processed in the standard construction.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Feeding system

We offer a range of very solid roller conveyors in various designs with solid rollers or simple design for small loads.Request a Quote Supplied by RSA Cutting Technologies Ltd -

H 250 Saw

The H 250 is an extremely strong production saw for tubes, sections and solid bars made of steel, stainless steel and non-ferrous metal designed for mitre cuts up to 45°.Request a Quote Supplied by RSA Cutting Technologies Ltd -

H 300 Saw

The H 300 is a very powerful machine for tubes, sections and solid bars made of steel, stainless steel and non-ferrous metal designed for mitre cuts up to 45°.Request a Quote Supplied by RSA Cutting Technologies Ltd -

H 350 H Saw/H 450 H Saw

The H 350 H and H 450 H are semiautomatic circular mitre saws for tubes, sections and solid bars made of steel, stainless steel and non-ferrous metal designed for diameters of up to 120 mm respectively 160 mm.Request a Quote Supplied by RSA Cutting Technologies Ltd -

H 350 Saw

The H 350 is a versatile, powerful production saw for tubes, sections and solid bars made of steel, stainless steel and non-ferrous metal designed for mitre cuts on both sides up to 45° for a clamping range up to 185 mm.Request a Quote Supplied by RSA Cutting Technologies Ltd -

H 450 Saw

The H 450 is a versatile, powerful production saw for tubes, sections and solid bars made of steel, stainless steel and non-ferrous metal designed for mitre cuts on both sides of up to 45° for a clamping range up to 200 mm. The H 450 is in that size unique on the market.Request a Quote Supplied by RSA Cutting Technologies Ltd