100% SAF™ Needlefelt Now Available

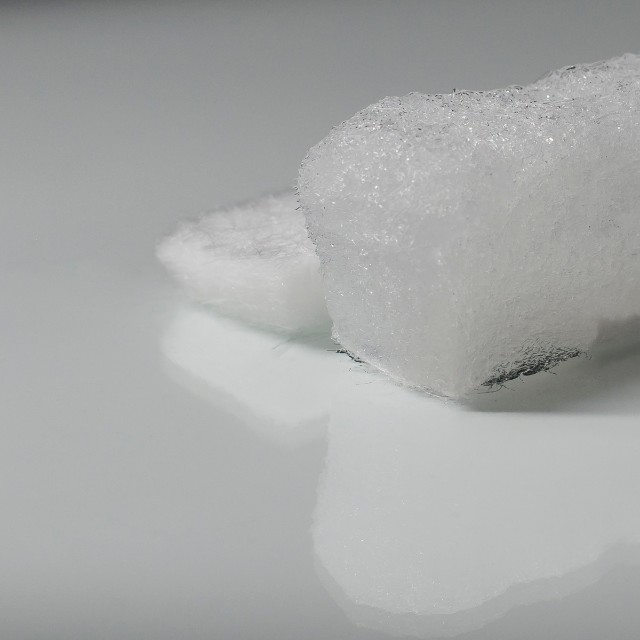

11 September 2018Technical Absorbents is excited to announce the launch of a completely unique superabsorbent fabric. The patent-pending 100% SAF™ needlefelt nonwoven has been in development and testing for some time and is now commercially available.

Superabsorbent SAF™ needlefelt fabrics are already used in many applications and, since the installation of its own line in 2015, Technical Absorbents has created a large portfolio of absorbent fabrics and has supported a number of new product developments. The latest fabric is truly unique and will open up the doors to applications that require a fully maceratable superabsorbent solution.

“The development of a fabric that contains only SAF™ and no other synthetic, natural or binder fibres is extremely exciting,” explains Product Development Director Dr Mark Paterson. “We are not aware of anyone else that can manufacture such a fabric and this opens up the opportunity for new product forms. There is no other 100% superabsorbent fabric currently available.”

“We particularly see a potential for its use in spill capture products, such as those used in hospitals to contain bloods, urines and other liquids that need to be managed safely, hygienically and effectively.”

The 2m wide needlefelt line can produce absorbent fabrics in basis weights from 130 to 1000gsm. To help protect the fibre during processing, the line is housed in a controlled humidity environment. Other non-absorbent fabrics can also be manufactured on the line, i.e. 100% polyester. Short order trial runs can also be facilitated where commercially viable.

“Initially, the line was used for research and development (R&D) as well as making commercial products,” continues Mark. “The first couple of years saw us develop our product range – containing up to 80% SAF™ – which are now used in many different applications from medical to filtration. The new 100% SAF™ fabric is the first of a number of products we have developed as we strive to look for new opportunities for our core SAF™ technology.”

“Small hand samples of the new fabric are now available via our ecommerce facility and we are also willing to undertake short-order trial runs, where possible, to help support potential customers with development programs.”