V and F Sheet Metal Co Ltd

V and F Sheet Metal are a UK Hampshire based sheet metal fabrication, sheet metal work and sub-contract engineering company. We provide sheet metal manufacturing services including CNC punching, CNC laser cutting, CNC bending, welding and press work. Using the latest CAD/CAM software modelling for the best accuracy and speed of sheet metal blank development for our in house CNC punching and CNC laser cutting processes. Supporting a wide range of industries in the UK from electronics to lighting, heating and audio.

Established in Fareham, Hampshire in 1985, with the ability to handle engineering projects from one off small batches of bespoke sheet metal work to high volume power press work V and F Sheet Metal are flexible enough to offer you the complete sub-contract sheet metal fabrication service for your growing company. Regular deliveries to Portsmouth, Southampton, Winchester, Eastleigh, Andover, Basingstoke and other towns in Hampshire from our factory in Fareham is easy. Over-night pallet and small package deliveries right across the UK for those who need it is offered to ease sheet metal component supply.

We have grown to a size where we can offer a complete sub-contract sheet metal fabrication and sheet metal work service to our customers right across the UK. This can include advice on the suitability of sheet metal work designs for manufacturing, sub-assembly work or sub-contract finishing and treatments to your specification e.g. zinc plating, alocrom 1200 / 1000, iridite NCP, surtec 650, silver and black anodising, powder coating, wet painting and screen printing. Continually investing in the latest CNC manufacturing equipment and CAD/CAM software enables us to offer the best combination of quality and price to suit your sub-contract engineering and sheet metal fabrication requirements.

We have a long history of working with UK based lighting companies to reduce their sheet metal fabrication costs and improve the quality of their sub-contract engineering/sheet metal work projects. With many standard CNC punching tools and material set-up costs can be kept to a minimum when considering new sheet metal fabrication projects.

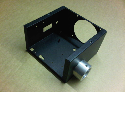

- Sheet Metal Enclosures and sheet metal housings for the electronics industry

- Reflectors and sheet metal fabrications for the UK lighting industry

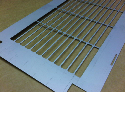

- Sheet Metal Perforated Ventilation and Speaker grilles for the heating and audio industries

- Front panel electronics and rack mount sheet metal work

- Welded assemblies - thin gauge to 6mm sheet metal fabrications in ferrous and non-ferrous materials

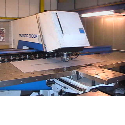

- CNC punching using Trumpf CNC punch presses

- CNC laser cutting with our Trumpf 3030 3KW fibre laser cutting machine

- CAD/CAM processes supported by Radan 3D and 2D software to aid CNC punching and laser cutting

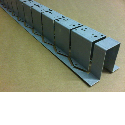

- Sheet Metal CNC bending up to 3.0M long (7 press brakes), including 3 Trumpf 7036 CNC press brakes and a 3M Safan e-Brake CNC press brake

- Tig, Mig, Gas, Spot and Stud sheet metal fabrication welding capacity

- Power press sheet metal work up to 50 tons with custom press tools

Where can I get sheet metal work? Look no further if you are looking for CNC punching, CNC laser cutting, CNC bending and other sheet metal working processes:

For further information and to discuss your personal sheet metal project requirements call us on 01489 577786.

For more information about sheet metal please visit this page What is Sheet Metal Work and how is it made?

-

Steel sheet fabrications manufactured to your own bespoke engineering designs

11 April 2024https://www.vandf.co.uk/blog/steel-sheet-fabrication-manufactured-to-your-bespoke-designs/

In the realm of steel sheet fabrication, precision and customisation are paramount. Bespoke CNC laser cutting, CNC punching, and CNC folding techniques are indispensable tools in achieving these objectives.

Firstly, CNC laser cutting offers unparalleled accuracy and versatility. By harnessing the power of a focused laser beam, intricate shapes and patterns can be effortlessly cut from steel sheets with exceptional precision. This capability is crucial for creating intricate designs or achieving tight tolerances, ensuring the final product meets exact specifications. Whether it's intricate filigree patterns or precise geometric shapes, CNC laser cutting empowers designers to bring their visions to life with uncompromising accuracy.

Secondly, CNC punching provides a cost-effective solution for producing a wide range of hole sizes and shapes in steel sheet fabrication. Utilising computer-controlled machinery, CNC punching offers rapid production speeds and consistent results, making it ideal for high-volume manufacturing. By incorporating features such as embossing, extrusions, or louvers directly into the fabrication process, CNC punching enhances the efficiency and functionality of the final product. This versatility enables designers to optimise the design for both aesthetic appeal and functional performance.

Finally, CNC folding adds the finishing touches to steel sheet fabrications, transforming flat sheets into complex three-dimensional structures with precision bends and folds. By precisely controlling the angle and depth of each bend, CNC folding ensures dimensional accuracy and repeatability, essential for achieving a seamless fit and finish in the assembly process. This capability enables designers to create custom enclosures, cabinets, or brackets tailored to specific application requirements, optimising space utilisation and structural integrity.

In summary, bespoke CNC laser cutting, CNC punching, and CNC folding are indispensable tools in the arsenal of a design engineer specialising in steel sheet fabrication. By harnessing these advanced techniques, designers can achieve unparalleled precision, versatility, and customisation, ensuring the final product meets the highest standards of quality and performance.

-

Standard sheet metal thicknesses and their common manufactured applications

3 April 2024https://www.vandf.co.uk/blog/standard-sheet-metal-thicknesses-and-their-common-applications/

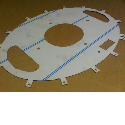

In the lighting industry, the manufacturing of steel sheet metal brackets demands precision and efficiency to meet the rigorous standards of quality and performance. The process typically involves a combination of advanced technologies such as laser cutting, CNC punching, and CNC bending to produce components with exact specifications.

Laser cutting is a pivotal step in the fabrication process, where a high-powered laser beam is used to precisely cut through the 1.2mm thick steel sheets. This technology allows for intricate designs and complex shapes to be achieved with minimal material wastage. By programming the laser cutter with precise measurements, each bracket can be cut with accuracy down to the micron, ensuring consistency across the production line.

Following laser cutting, CNC punching is employed to create holes, slots, and other features necessary for assembly and attachment. CNC punching machines use computer-controlled movements to precisely punch through the steel sheets, creating uniform holes with high efficiency. This step enables the brackets to be seamlessly integrated into the final lighting fixtures while maintaining structural integrity.

Finally, CNC bending is utilized to shape the flat-cut steel sheets into the desired bracket form. By programming the CNC bending machine with the specific bending angles and dimensions, the steel sheets are accurately bent into shape with minimal distortion or deformation. This process ensures that each bracket conforms to the exact requirements of the design, allowing for easy installation and optimal functionality within the lighting fixtures.

Overall, the integration of laser cutting, CNC punching, and CNC bending technologies enables the efficient and precise manufacturing of 1.2mm thick steel sheet metal brackets for the lighting industry. This advanced approach ensures the production of high-quality components that meet the demands of modern lighting applications.

-

Bespoke sheet metal brackets manufactured in the UK

22 March 2024Custom sheet metal brackets offer a multitude of advantages when it comes to industrial lighting applications, providing tailored solutions that enhance functionality, durability, and aesthetics. By partnering with a reputable manufacturer like V and F Sheet Metal, companies can unlock a range of benefits that cater specifically to their unique requirements.

One key advantage of designing custom sheet metal brackets is optimized fit and compatibility. Industrial lighting fixtures often require precise positioning and alignment to ensure efficient illumination. Off-the-shelf brackets may not offer the exact dimensions needed, leading to compromises in performance and stability. However, with custom brackets, manufacturers can tailor the design to perfectly accommodate the specific dimensions and mounting requirements of their lighting fixtures. This ensures a seamless integration and maximizes the effectiveness of the lighting system.

Moreover, custom brackets allow for the incorporation of additional features and functionalities that enhance performance and longevity. For instance, reinforcement ribs, gussets, or specialized mounting points can be strategically integrated into the design to improve structural integrity and withstand harsh environmental conditions. This customization ensures that the brackets can endure heavy loads, vibrations, and exposure to elements, prolonging the lifespan of the lighting fixtures and reducing maintenance costs.

Aesthetics also play a crucial role in industrial environments, where lighting fixtures often serve as both functional elements and design accents. Custom sheet metal brackets offer the flexibility to achieve the desired aesthetic appeal, whether it's through unique shapes, finishes, or branding elements. By aligning the bracket design with the overall design language of the facility or product line, manufacturers can create visually cohesive and appealing lighting solutions that enhance the overall ambiance of the space.

V and F Sheet Metal, with its expertise in custom sheet metal fabrication, exemplifies the capabilities needed to realize these advantages. Their gallery showcases a diverse range of custom bracket designs, highlighting the versatility and precision achievable through bespoke fabrication. From simple L-shaped brackets to complex multi-angle configurations, the examples demonstrate how custom brackets can address varied application needs while maintaining high standards of quality and craftsmanship. Collaborating with such a specialist enables companies to harness the full potential of custom sheet metal brackets for their industrial lighting projects, achieving superior performance, durability, and aesthetics.

-

Where can I buy custom sheet metal fabrications in the UK?

13 March 2024https://www.vandf.co.uk/blog/where-can-i-buy-custom-sheet-metal-fabrications-in-the-uk/

When it comes to acquiring custom sheet metal fabrications, V and F Sheet Metal emerges as a beacon of reliability and precision. Specializing in catering to the unique needs of various industries, they excel in providing top-notch solutions tailored to specific requirements. Their expertise shines particularly in the lighting industry, where intricate designs and high-quality finishes are paramount.

For instance, in the lighting industry, where aesthetics and functionality intertwine seamlessly, V and F Sheet Metal's capabilities come to the fore. From creating bespoke lighting enclosures to intricate reflectors and diffusers, their proficiency in manipulating sheet metal is evident. By leveraging advanced techniques such as laser cutting, they ensure precise cuts that adhere to the most exacting specifications, essential for achieving the desired lighting effects.

Laser cutting, a core aspect of V and F Sheet Metal's repertoire, epitomizes efficiency and accuracy in metal fabrication. Through the utilization of high-powered lasers, intricate shapes and patterns can be effortlessly etched onto various metals, enabling the realization of intricate lighting designs. This method not only facilitates precise cutting but also minimizes material wastage, making it a cost-effective solution for both large-scale production runs and bespoke one-off projects.

Furthermore, V and F Sheet Metal's commitment to quality extends beyond mere fabrication. Their comprehensive approach encompasses the entire production process, from initial design consultation to final finishing touches. By fostering close collaboration with clients, they ensure that every aspect of the fabrication aligns with the client's vision and requirements, resulting in a product that not only meets but exceeds expectations.

In addition to their prowess in laser cutting, V and F Sheet Metal boasts a diverse array of manufacturing capabilities, including CNC punching, CNC bending, Tig and Mig welding, and powder coating. This multifaceted approach allows them to tackle a wide spectrum of projects with unparalleled versatility and expertise.

In essence, choosing V and F Sheet Metal for custom sheet metal fabrications guarantees not only superior quality and precision but also a seamless journey from concept to completion. Whether for the lighting industry or beyond, their dedication to excellence ensures that every project is executed with the utmost professionalism and craftsmanship.

-

Where can I get custom sheet metal brackets in the UK?

5 March 2024If you're in the UK and in need of custom sheet metal brackets, you're in luck! There are several options available to you to get the precise brackets you require for your project. One excellent resource for custom sheet metal brackets in the UK is V and F Sheet Metal.

V and F Sheet Metal is a reputable company with extensive experience in manufacturing a wide range of sheet metal components, including brackets. They offer bespoke fabrication services tailored to meet your specific requirements, ensuring that you get precisely the brackets you need for your project.

Whether you need simple L-shaped brackets or more complex designs, V and F Sheet Metal can accommodate your needs. They utilize advanced equipment and skilled craftsmen to produce high-quality brackets with precision and efficiency.

Furthermore, V and F Sheet Metal prides itself on its commitment to customer satisfaction. They work closely with their clients throughout the fabrication process, from initial design to final production, to ensure that the finished product meets or exceeds expectations.

In addition to their expertise in sheet metal fabrication, V and F Sheet Metal also offers competitive pricing and fast turnaround times, making them an excellent choice for your custom bracket needs.

So if you're searching for custom sheet metal brackets in the UK, look no further than V and F Sheet Metal. With their experience, expertise, and dedication to quality, you can trust them to deliver the perfect brackets for your project.

https://www.vandf.co.uk/blog/where-can-i-get-custom-sheet-metal-brackets-in-the-uk/

-

Sheet metal forming sub-contract components in Hampshire UK

28 February 2024When it comes to sheet metal forming sub-contract components in Hampshire, UK, precision and reliability are paramount. Companies like V and F Sheet Metal specialize in providing top-notch sheet metal fabrication services to meet various industry needs.

In Hampshire, UK, V and F Sheet Metal exemplifies excellence in sheet metal forming subcontract components. Leveraging state-of-the-art machinery and a skilled workforce, they cater to diverse requirements, from simple brackets to complex enclosures.

For instance, their CNC punching capabilities enable rapid production of intricate profiles with high accuracy. This technology allows for the creation of precise features, such as holes, slots, and forms, ensuring adherence to client specifications.

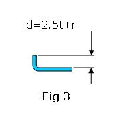

Moreover, V and F Sheet Metal's CNC bending services facilitate the shaping of metal sheets into desired geometries with exceptional consistency. With a wide range of press brake tooling and bending expertise, they accommodate varying material thicknesses and bend radii, delivering components that meet stringent quality standards.

Additionally, their welding and assembly capabilities ensure seamless integration of multiple components, enhancing the functionality and structural integrity of the final product.

In conclusion, for sheet metal forming sub-contract components in Hampshire, UK, V and F Sheet Metal stands out as a reliable partner, offering comprehensive solutions tailored to meet the unique requirements of diverse industries. With a focus on precision, efficiency, and quality, they continue to excel in the field of sheet metal fabrication.

https://www.vandf.co.uk/blog/sheet-metal-forming-sub-contract-components-in-hampshire-uk/

-

CNC punching sheet metal work in Hampshire UK during 2024

20 February 2024https://www.vandf.co.uk/blog/cnc-punching-sheet-metal-work-in-the-uk-during-2024/

The Evolution of CNC Punching Sheet Metal Work in 2024

In the heart of Hampshire UK, the audio industry is witnessing a transformative evolution in CNC punching sheet metal work. As a sales engineer deeply entrenched in this dynamic sector, I'm thrilled to shed light on the cutting-edge advancements reshaping our manufacturing processes.

Punching sheet metal work has always been pivotal in crafting high-quality audio equipment. However, in 2024, it's reaching unprecedented levels of precision and efficiency. With CNC technology at the forefront, manufacturers are pushing boundaries like never before.

Imagine the intricacy of speaker grills meticulously punched with flawless precision, enhancing both aesthetics and functionality. In the competitive landscape of audio equipment, every detail matters, and CNC punching sheet metal work ensures perfection at every turn.

Moreover, CNC technology isn't just about precision; it's also about speed and scalability. In Hampshire UK, manufacturers are meeting skyrocketing demands for premium audio products without compromising on quality, thanks to the rapid turnaround times enabled by CNC punching sheet metal work.

Whether it's crafting amplifier chassis or speaker enclosures, CNC punching sheet metal work is the cornerstone of innovation in the audio industry. And here in Hampshire UK, we're proud to lead the charge into a future where excellence is not just a standard but an expectation.

-

Fining a sheet metal working company in Southampton, Hampshire

25 January 2024Finding the right sheet metal working company in Southampton is a critical task for businesses and industries seeking reliable and high-quality fabrication services. Southampton, with its industrial landscape, demands precision and expertise in sheet metal work to meet diverse needs.

First and foremost, it's essential to consider the company's experience and track record. A reputable sheet metal working company should have a proven history of delivering successful projects and demonstrating expertise in various fabrication techniques. Examining past projects, client testimonials, and industry certifications can provide valuable insights into the company's capabilities.

Additionally, a comprehensive understanding of the company's range of services is crucial. Southampton-based businesses should look for sheet metal fabricators that offer a broad spectrum of capabilities, including laser cutting, CNC punching, bending, welding, and finishing processes. Versatility ensures that the chosen company can handle a diverse range of projects, from intricate prototypes to large-scale production runs.

Furthermore, attention to quality assurance and compliance with industry standards is paramount. A reliable sheet metal working company in Southampton should adhere to stringent quality control measures, ensuring that fabricated components meet or exceed specified tolerances and standards. Compliance with industry regulations, such as ISO certifications, demonstrates a commitment to quality and reliability.

Lastly, effective communication and collaboration are key factors. A reputable company should be transparent in its communication, providing clients with updates on project progress, timelines, and any potential challenges. The ability to collaborate seamlessly ensures that the final product aligns with the client's vision and requirements.

In conclusion, finding the right sheet metal working company in Southampton requires thorough research, considering factors such as experience, services offered, quality assurance, and communication. By selecting a reliable partner, businesses can ensure the success of their sheet metal fabrication projects in Southampton's dynamic industrial landscape.

https://www.vandf.co.uk/blog/bespoke-sheet-metal-brackets-manufactured-in-the-uk/

V and F Sheet Metal have been manufacturing sub-contract sheet metal work for nearly 40 years in the Southampton area. Contact us for a quote today on your next sheet metal project.

-

Sub-contract custom sheet metal housings produced to your own designs

5 January 2024Designing custom sheet metal housings for your own projects offers a myriad of advantages, enhancing functionality, aesthetics, and overall performance. One notable advantage is tailored precision. By crafting bespoke sheet metal housings, engineers can ensure a perfect fit for their specific components, optimizing the integration of complex systems. This precision minimizes gaps, enhances structural integrity, and improves overall efficiency.

Customization also enables engineers to meet unique design requirements, accommodating specialized functionalities or space constraints. This flexibility is crucial in various industries, ranging from electronics to automotive applications. For instance, at www.vandf.co.uk, engineers can access a wide range of customization options, allowing them to adapt sheet metal housings to diverse project needs.

Moreover, custom designs provide an opportunity to optimize material selection. Engineers can choose materials based on their specific properties, such as durability, conductivity, or corrosion resistance. This tailored approach not only enhances the longevity of the housing but also contributes to cost-effectiveness by avoiding over-specification.

Aesthetics and branding are equally important considerations. Custom sheet metal housings offer the chance to create visually appealing designs that align with a brand's identity. Vandf.co.uk, for example, showcases examples of customized sheet metal components that not only meet functional requirements but also elevate the visual appeal of the final product.

In conclusion, the advantages of designing custom sheet metal housings extend beyond mere functionality. Tailored precision, flexibility, optimal material selection, and enhanced aesthetics contribute to the overall success of engineering projects. Accessing the capabilities provided by www.vandf.co.uk exemplifies how customization can elevate the quality and performance of sheet metal components in diverse applications.

https://www.vandf.co.uk/blog/custom-sheet-metal-housings-manufactured-to-your-designs/

-

Designing bespoke sheet metal work for electronics enclosures

21 December 2023As an electro-mechanical design engineer, incorporating bespoke sheet metal work into your designs can yield substantial cost savings and enhance overall project efficiency. Customized sheet metal solutions, particularly in the design of enclosures, offer numerous advantages that contribute to both financial and operational benefits.

Firstly, bespoke sheet metal work allows for precise tailoring of enclosures to fit the exact specifications of the equipment they house. This eliminates unnecessary material waste, as standardized off-the-shelf enclosures often result in excess materials that drive up costs. By optimizing the dimensions and features of the enclosure to the specific requirements of the electronics or machinery, you can significantly reduce material expenses.

Moreover, customization enables the integration of features such as cable management, cooling systems, and mounting options directly into the sheet metal design. This not only enhances the functionality of the enclosure but also reduces the need for additional components or modifications, streamlining the assembly process. Consequently, labor costs associated with assembly and installation decrease, contributing to overall project savings.

https://www.vandf.co.uk/blog/sheet-metal-in-electronics-precision-enclosures-and-cases/

Additionally, bespoke sheet metal work allows for the use of cost-effective yet durable materials, tailored precisely to the application. This ensures that the final product meets performance requirements without unnecessary expenditures on premium materials.

In summary, investing in bespoke sheet metal work for custom enclosures can result in substantial cost savings by minimizing material waste, optimizing functionality, and reducing labor expenses. The tailored approach not only enhances the efficiency of the design process but also ensures that the final product aligns perfectly with the specific needs of the electro-mechanical system.

-

How can laser cutting sheet metal help me save money

20 December 2023https://www.vandf.co.uk/tooling/what-is-laser-cutting/

Laser cutting is a highly efficient and cost-effective method in the manufacturing of sheet metal products, particularly in the electronics industry. As a sheet metal design engineer, I recognize the numerous advantages that laser cutting offers, contributing significantly to cost savings.

One key benefit is the precision and accuracy of laser cutting, which allows for intricate and complex designs with minimal material wastage. In the electronics industry, where precision is paramount, laser cutting ensures that intricate patterns for components like chassis, brackets, and enclosures can be achieved with high repeatability. This precision not only enhances the quality of the final product but also minimizes the need for additional finishing processes, reducing both time and costs.

Furthermore, laser cutting is a rapid and versatile process, making it ideal for prototyping and short production runs. Design changes can be quickly implemented without the need for expensive tooling adjustments, streamlining the product development cycle. In electronics, where rapid technological advancements demand agile manufacturing processes, this flexibility is invaluable.

Additionally, the ability of laser cutting to handle a variety of materials, including stainless steel, aluminum, and copper commonly used in electronics, adds to its cost-effectiveness. The elimination of the need for multiple tool changes for different materials simplifies the manufacturing process and reduces downtime, leading to overall cost savings.

In conclusion, as a sheet metal design engineer in the electronics industry, leveraging laser cutting technologies is not just about precision and speed but also a strategic approach to optimizing costs throughout the product development and manufacturing phases.

-

Bespoke / Custom sheet metal manufactured in the UK

18 December 2023https://www.vandf.co.uk/blog/bespoke-sheet-metal-fabrications-and-their-uses-today-in-the-uk/

V and F Sheet Metal stands at the forefront of bespoke sheet metal fabrications in the United Kingdom, offering precision manufacturing solutions that cater to diverse industries. With a focus on excellence and innovation, our team of skilled engineers combines cutting-edge technology with traditional craftsmanship to deliver high-quality, tailor-made sheet metal components.

In the dynamic field of bespoke sheet metal manufacturing, V and F Sheet Metal has established itself as a reliable partner, particularly within the lighting industry. Our expertise extends to crafting intricate and customized sheet metal parts for various lighting applications, ranging from lamp reflectors, LED gear trays, lamp holders, to structural components.

In the lighting sector, our commitment to precision is exemplified through the production of intricately designed fixtures and enclosures. Utilizing advanced CNC punching and laser cutting technologies, we can intricately cut, shape, and form sheet metal to meet the unique specifications of our clients. Our welding and fabrication capabilities ensure that the components are seamlessly joined, providing structural integrity and a polished finish.

V and F Sheet Metal's dedication to quality extends beyond the manufacturing process. We collaborate closely with our clients, offering design assistance and material selection guidance to ensure the optimal performance and aesthetic appeal of the final product. Our ability to adapt to the evolving needs of the lighting industry sets us apart, making V and F Sheet Metal the preferred choice for those seeking bespoke sheet metal solutions in the UK.

-

Bespoke sheet metal fabrications : Precision enclosures and case components

13 December 2023https://www.vandf.co.uk/blog/sheet-metal-in-electronics-precision-enclosures-and-cases/

In the electronics industry, bespoke sheet metal fabrications play a pivotal role in the creation of precision enclosures and case components. These specialized components are integral to housing delicate electronic equipment, providing both structural support and shielding against external factors.

Bespoke sheet metal fabrications offer unparalleled precision, ensuring that the enclosure precisely fits the dimensions and specifications of the electronic device. This tailored approach is particularly crucial in the manufacturing of circuit boards, ensuring a seamless integration of components within a confined space. For example, in the production of custom server racks, bespoke sheet metal fabrications enable the creation of intricately designed enclosures that accommodate various server units with exacting precision.

Moreover, the use of bespoke sheet metal fabrications extends beyond mere functionality to embody aesthetic considerations. In consumer electronics, sleek and visually appealing enclosures are as vital as their functional aspects. Manufacturers leverage precision sheet metal techniques to craft elegant cases for devices such as high-end audio equipment, ensuring not only optimal performance but also a sophisticated and polished appearance.

The versatility of bespoke sheet metal fabrications allows engineers to experiment with diverse materials, from aluminum to stainless steel, adapting to the specific requirements of the electronics industry. This adaptability is evident in the creation of robust and heat-resistant enclosures for industrial electronic control panels, safeguarding sensitive components from environmental factors.

In essence, bespoke sheet metal fabrications serve as the cornerstone for achieving precision, durability, and aesthetics in the production of enclosures and case components in the electronics industry, emphasizing the importance of tailored solutions for diverse electronic applications.

-

Sheet metal in Electronics: Precision enclosures and cases

12 December 2023https://www.vandf.co.uk/blog/sheet-metal-in-electronics-precision-enclosures-and-cases/

Custom-designed and manufactured sheet metal cases offer distinct advantages in meeting the unique requirements of the electronics industry. One key benefit lies in their tailored design, allowing engineers to create enclosures that precisely fit the dimensions and specifications of electronic components. This bespoke approach ensures optimal space utilization, minimizing wasted space and maximizing the efficiency of the overall system.

Furthermore, custom sheet metal cases enable engineers to incorporate specific features, such as precision-cut openings, ventilation slots, and mounting points, tailored to the needs of the electronics they house. This level of customization enhances the overall functionality, accessibility, and aesthetics of the final product. The ability to choose materials and finishes also provides flexibility in achieving desired durability, corrosion resistance, and visual appeal.

From a production standpoint, custom sheet metal fabrication allows for cost-effective batch manufacturing, reducing material waste and promoting sustainability. The precision achievable in manufacturing processes ensures tight tolerances and consistent quality across multiple units, contributing to the reliability and longevity of electronic devices.

In summary, V and F Sheet Metal can off the advantages of custom-designed and manufactured sheet metal cases for the electronics industry encompass precise fitting, tailored features, material flexibility, and efficient production processes, collectively contributing to enhanced functionality, durability, and overall product excellence.

-

Sheet metal manufacturing of housings and brackets in the UK

7 December 2023https://www.vandf.co.uk/blog/sheet-metal-manufacturing-of-housings-and-brackets/

As a manufacturing engineer, I understand the critical role that bespoke sheet metal housings and brackets play in the electronics industry. Our sub-contract manufacturing services specialize in crafting tailored solutions for electronic devices, ensuring optimal functionality and structural integrity. Collaborating with us means leveraging our expertise to produce precision-engineered housings that seamlessly accommodate intricate circuitry in devices like advanced medical instruments or cutting-edge communication devices.

Our process prioritizes material selection, precision cutting, and meticulous assembly, meeting the rigorous demands of electronic applications. By outsourcing the manufacturing of sheet metal components, companies can focus on core competencies while benefiting from cost-effective, high-quality solutions. From custom smartphone casings to intricately designed brackets for industrial machinery, our sub-contract manufacturing ensures that your electronics not only meet but exceed industry standards, solidifying your position at the forefront of technological innovation.

-

Custom sheet metal brackets manufactured to your own designs

6 December 2023https://www.vandf.co.uk/gallery/bracket-angle-gallery/

Bespoke sheet metal brackets are integral to the electronics industry, playing a critical role in the design and functionality of various electronic components. One prominent application is within 19" rack mount systems, where customized brackets are employed for securing and organizing electronic equipment.

In the realm of 19" rack mount systems, which are standard in data centers, telecommunication facilities, and audio/video setups, bespoke sheet metal brackets serve as the backbone for mounting servers, switches, and other critical hardware. These brackets are tailored to the specific dimensions and requirements of the equipment, ensuring a snug fit and optimal functionality. Precision is paramount in this context, as even the slightest deviation can compromise the integrity of the entire system.

The versatility of bespoke sheet metal brackets allows engineers to address specific challenges posed by unique electronic configurations. Whether accommodating non-standard equipment dimensions or integrating additional features like cable management, engineers can tailor brackets to meet the exact needs of the application. This level of customization enhances the efficiency of rack systems, streamlining installations and maintenance.

Furthermore, bespoke brackets contribute to the structural integrity and durability of 19" rack mount systems. By leveraging high-quality materials and precision manufacturing techniques, engineers can ensure that these brackets provide robust support, minimizing the risk of equipment damage due to vibrations or shocks.

The electronics industry's rapid evolution demands adaptability, and bespoke sheet metal brackets offer a flexible solution. As technologies advance and new electronic devices emerge, engineers can quickly design and produce custom brackets to accommodate these innovations. This adaptability extends the lifespan of 19" rack mount systems, allowing them to remain relevant and functional amid changing technological landscapes.

In conclusion, bespoke sheet metal brackets are indispensable in the electronics industry, especially within 19" rack mount systems. Their role in customization, structural support, and adaptability exemplifies their significance in ensuring the seamless integration and performance of electronic components in various applications.

-

Sheet metal folding in the UK, custom sub-contract sheet metal work

5 December 2023Sheet Metal Folding

Sheet metal folding has undergone a transformative evolution with the integration of modern CNC press brake machines. These cutting-edge devices have revolutionized the metal fabrication industry, providing unparalleled precision and efficiency in shaping sheet metal. CNC (Computer Numerical Control) technology allows for intricate designs and complex bends, ensuring a high level of accuracy in every fold.

The CNC press brake machines operate through programmed instructions, enabling consistent and repeatable results with minimal human error. This automation not only increases productivity but also reduces production time, making it a cost-effective solution for large-scale manufacturing. Additionally, these machines offer versatility by accommodating various materials and thicknesses, expanding the range of applications in industries such as aerospace, automotive, and electronics.

Furthermore, the user-friendly interface of modern CNC press brakes simplifies the programming process, allowing operators to create intricate patterns and geometries effortlessly. The combination of advanced technology and skilled craftsmanship has elevated sheet metal folding to new heights, providing manufacturers with a powerful tool to meet the demands of precision engineering in the 21st century.

If you have a project that requires sheet metal folding, please contact us and we will be happy to provide you with quotation options.

https://www.vandf.co.uk/blog/sheet-metal-folding-in-the-uk-ask-for-a-quote-today/

-

Looking for a flexible sheet metal working company to support your manufacturing needs

29 November 2023https://www.vandf.co.uk/tooling/what-is-cnc-bending/

Folded sheet metal components stand as a great example of precision engineering and versatility in modern manufacturing. This technique involves manipulating flat sheets of metal, often aluminum or steel, into three-dimensional forms through a sequence of carefully executed bends. The result is a seamless, structurally sound component that finds applications across various industries.

One notable advantage of folded sheet metal components is their strength-to-weight ratio. The folding process increases the rigidity of the material, providing robustness without unnecessary added weight. This is particularly crucial in industries where lightweight yet durable components are imperative for efficiency and performance.

Furthermore, the flexibility in design is a key attribute. The ability to create complex geometries and intricate shapes allows for the production of custom components tailored to specific needs. This adaptability is especially beneficial in industries such as aerospace, automotive, and electronics, where unique and space-efficient designs are often paramount.

The precision achieved through modern CNC (Computer Numerical Control) technology enhances the accuracy of each fold, ensuring consistency and repeatability in mass production. This not only streamlines manufacturing processes but also contributes to the overall quality and reliability of the final product.

In conclusion, folded sheet metal components exemplify the marriage of form and function in engineering. Their strength, lightweight nature, and design flexibility make them a cornerstone in the production of diverse and sophisticated components across industries, showcasing the prowess of modern manufacturing techniques.

-

Custom made sheet metal brackets made to your designs - ask for details today

28 November 2023Investing in custom-made sheet metal brackets offers a range of advantages that play a pivotal role in optimizing performance, structural integrity, and overall efficiency across various industries. One of the primary benefits is the precise tailoring of brackets to meet specific requirements. Customization allows manufacturers to design brackets that perfectly fit the dimensions and specifications of the components they are intended to support. This precision ensures optimal alignment and functionality, reducing the risk of errors or malfunctions in the assembly.

Furthermore, custom sheet metal brackets can be engineered to address unique challenges and accommodate specialized applications. Whether it's adapting to tight spaces, unusual angles, or specific load-bearing requirements, the flexibility of customization ensures that the brackets are designed to meet the exact needs of the project. This adaptability is particularly valuable in industries where standard, off-the-shelf brackets may not provide an adequate solution.

The material strength and durability of sheet metal contribute significantly to the robustness of custom brackets. Manufacturers can choose from a variety of high-quality materials, such as stainless steel or aluminum, depending on the application's demands. This ensures that the brackets not only provide reliable support but also withstand environmental factors like corrosion, moisture, and temperature variations, enhancing the longevity of the entire system.

https://www.vandf.co.uk/gallery/bracket-angle-gallery/

Custom sheet metal brackets also contribute to cost-effectiveness by minimizing material waste. The ability to design brackets with precise dimensions reduces the need for excess material, optimizing resource utilization and minimizing production costs. This efficiency is not only environmentally friendly but also reflects positively on the overall economic feasibility of the manufacturing process.

In conclusion, the advantages of purchasing custom-made sheet metal brackets extend beyond simple customization. They encompass precision, adaptability, material strength, and cost-effectiveness, making them a valuable investment for industries that prioritize performance, durability, and efficiency in their applications.

-

CNC folding custom made mild steel sheet metal covers

27 November 2023https://www.vandf.co.uk/tooling/what-is-cnc-bending/

CNC (Computer Numerical Control) folding in sheet metal work offers a multitude of advantages that have revolutionized the manufacturing industry. One of the primary benefits is precision. CNC folding ensures accuracy and consistency in bending sheet metal, resulting in high-quality finished products with tight tolerances. The automation aspect of CNC folding contributes to increased efficiency and faster production rates. This not only reduces labor costs but also enables manufacturers to meet tight deadlines and handle large-scale production runs effectively.

Another advantage is versatility. CNC folding machines can handle a wide range of sheet metal thicknesses and materials, allowing for the production of diverse and complex components. The programmability of CNC systems facilitates quick and easy adjustments, making it possible to switch between different designs and prototypes with minimal downtime. Additionally, CNC folding eliminates the need for extensive manual labor and reduces the risk of errors, ensuring a safer working environment.

Cost-effectiveness is a significant perk of CNC folding in sheet metal work. The precise control over the folding process minimizes material waste, optimizing resource utilization and ultimately reducing overall production costs. Furthermore, the repeatability of CNC folding results in consistent product quality, reducing the likelihood of defects and the associated costs of rework.

In summary, CNC folding in sheet metal work offers advantages such as precision, efficiency, versatility, and cost-effectiveness. These benefits collectively contribute to the enhanced competitiveness and success of manufacturers in today's dynamic and demanding market.

-

Precision sheet metal work manufactured in the UK

23 November 2023https://www.vandf.co.uk/blog/precision-sheet-metal-work-manufactured-in-the-uk/

Precision sheet metal work offers numerous advantages, making it a preferred choice in various industries. Firstly, precision is inherent in the process, ensuring accurate and consistent fabrication of complex components. This accuracy leads to enhanced product quality and performance, critical for industries like aerospace, electronics, and automotive.

The versatility of precision sheet metal work is another key advantage. It accommodates a wide range of materials, including steel, aluminum, and copper, allowing manufacturers to select the most suitable material for their specific application. This flexibility extends to the thickness of materials, enabling the production of both thin and thick gauges, meeting diverse design requirements.

Cost-effectiveness is a significant benefit. Precision sheet metal fabrication reduces material waste through efficient nesting and optimization techniques. This not only lowers raw material costs but also minimizes environmental impact. Additionally, the use of Computer Numerical Control (CNC) machines enhances efficiency and reduces labor costs by automating the fabrication process.

The speed of production is noteworthy. Precision sheet metal work, especially when coupled with advanced technologies, allows for rapid prototyping and quick turnaround times. This agility is crucial in industries with dynamic market demands, providing a competitive edge.

The durability of precision sheet metal components is another advantage. The fabrication process enhances material strength and structural integrity, resulting in products with a longer lifespan and greater resistance to wear and tear. This durability is particularly valuable in applications where components are subjected to harsh environmental conditions or heavy usage.

Furthermore, precision sheet metal work facilitates complex designs and intricate detailing, allowing manufacturers to create highly customized components. This customization is vital in industries where unique specifications are required, such as in medical devices or specialized machinery.

In summary, precision sheet metal work offers advantages in terms of accuracy, versatility, cost-effectiveness, speed of production, durability, and customization. These factors collectively contribute to its widespread adoption across various industries, meeting the demands of modern manufacturing and engineering.

-

Manufacturing sheet metal brackets to your custom designs in the UK

22 November 2023The versatility of sheet metal fabrication is indeed remarkable, catering to a wide spectrum of industries such as lighting, heating, audio, and electronics. In the realm of lighting, sheet metal is commonly utilized for creating durable and aesthetically pleasing fixtures and enclosures. In heating applications, sheet metal components may form the basis for heating elements, ductwork, and enclosures, ensuring efficient heat transfer and distribution. In the audio industry, precision-cut sheet metal is often employed to manufacture speaker enclosures and structural components, contributing to both the acoustic performance and overall durability of audio equipment. Additionally, in the electronics sector, sheet metal is integral to the production of enclosures, chassis, and brackets, providing the necessary structural support and protection for sensitive electronic components. The adaptability of sheet metal in these diverse industries speaks to its importance as a foundational material for creating custom components that meet the specific needs of each application. If you have any specific details or features you'd like to emphasize regarding your sheet metal fabrication services, feel free to provide more information.

https://www.vandf.co.uk/blog/sheet-metal-mounting-brackets-how-are-they-manufactured/

-

Sheet metal brackets manufactured in the UK - How are they made?

21 November 2023Sheet metal brackets are essential components in various industries, playing a crucial role in providing structural support and stability to different assemblies. These brackets are typically made from materials such as aluminum, steel, or stainless steel, chosen for their strength, durability, and corrosion resistance. The manufacturing process involves cutting the sheet metal into the desired shape and then bending it to achieve the required angles and dimensions.

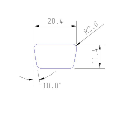

Bending sheet metal brackets requires precision and expertise to ensure the final product meets design specifications. The process often involves the use of specialized equipment, such as press brakes or other bending machines. The operator carefully sets up the machine to accommodate the specific dimensions and angles needed for the bracket. The sheet metal is then carefully positioned and clamped into place before the bending process begins.

During bending, the sheet metal undergoes plastic deformation, allowing it to take on the desired shape without cracking or compromising its structural integrity. The angle and radius of the bend are critical considerations, as they directly impact the bracket's functionality and fit within the overall assembly. Skilled operators may use a variety of bending techniques, such as air bending or bottoming, depending on the material and design requirements.

In addition to precision in the bending process, other factors, such as the thickness and type of sheet metal, must be considered to achieve optimal results. Proper tooling, including dies and punches, is selected based on the specific characteristics of the material and the bracket design.

In conclusion, the fabrication of sheet metal brackets involves a meticulous process of cutting and bending, with a focus on precision and attention to detail. Skilled operators and specialized equipment are essential to ensure that the brackets meet the required specifications and perform their intended function in various industrial applications.

https://www.vandf.co.uk/blog/sheet-metal-mounting-brackets-how-are-they-manufactured/

-

Looking for a sub-contract sheet metal manufacturing supplier?

16 November 2023If you're in search of a reliable sub-contract sheet metal supplier, your quest ends here. Our company prides itself on being a trusted partner for all your sheet metal needs. With a commitment to precision, quality, and timely delivery, we excel in providing customized solutions to meet your specific requirements. Our skilled team of professionals ensures that each project is executed with precision and attention to detail, guaranteeing the highest standards of craftsmanship. Whether you require components for industrial applications, construction projects, or any other sheet metal fabrication needs, we have the expertise and capabilities to deliver results that exceed expectations. Partnering with us means gaining access to a dedicated and experienced team committed to meeting your subcontracting sheet metal requirements with efficiency and excellence.

https://www.vandf.co.uk/blog/looking-for-a-sub-contract-sheet-metal-manufacturing-supplier/

-

Manufacturing sheet metal housings to your own designs

15 November 2023Manufacturing sheet metal housings is a complex and precise process that requires a harmonious blend of engineering expertise and cutting-edge technology. The journey begins with the careful selection of sheet metal, a decision influenced by factors such as the intended application, environmental conditions, and desired durability. Common choices include steel and aluminum, prized for their strength and formability. The selected metal undergoes a meticulous transformation through a series of steps, starting with cutting. Traditional methods like shearing or advanced techniques such as laser cutting define the initial shape of the housing. This phase is critical as it lays the foundation for the housing's structural integrity and functionality.

Following the cut, the sheet metal moves into the forming stage. This involves shaping the metal into the desired configuration through processes like bending, folding, or stamping. Precision is paramount during this stage to ensure uniformity and consistency in the final product. Welding may come into play, joining various components together to create a seamless, unified structure. The welding process requires a high level of skill to achieve strong and durable bonds between metal parts.

Surface finishing is the next crucial step in manufacturing sheet metal housings. Various treatments, such as powder coating or galvanization, are applied to enhance both the aesthetic appeal and the protective qualities of the housing. These treatments not only contribute to the visual aesthetics of the final product but also provide a protective layer, preventing corrosion and extending the lifespan of the housing. The choice of surface finish can be influenced by the intended environment of use, with considerations for factors like humidity, temperature, and exposure to corrosive elements.

Innovations in manufacturing techniques have played a significant role in shaping the landscape of sheet metal housing production. Advanced technologies, such as computer numerical control (CNC) machining, have elevated precision to new levels, allowing for intricate designs and complex geometries. Automation has streamlined the manufacturing process, improving efficiency and reducing the margin of error. Additionally, there is a growing emphasis on sustainability in the manufacturing industry, leading to the exploration of eco-friendly materials and processes in the production of sheet metal housings.

Sheet metal housings find application in a wide array of industries, from electronics and automotive to telecommunications and beyond. Their versatility and durability make them indispensable for protecting sensitive components and machinery, ensuring the safe and efficient operation of various devices. As technology continues to advance, the manufacturing of sheet metal housings will undoubtedly witness further innovations, pushing the boundaries of what is possible and setting new standards for quality and efficiency in the world of industrial design.

Contact V and F Sheet Metal at http://www.vandf.co.uk if you need a quote to manufacture your sheet metal housings.