Weldlogic Europe Ltd

For over 25 years Weldlogic has lead the market with innovations in micro-TIG and micro-Plasma welding. Its range of state of the art Linear and Computerised power sources are capable of delivering precise current, voltage and travel over programmable weld schedules. Along side these power sources are a range of welding lathes, turntables and linear seam welders. The company’s philosophy is to work in close partnership with its customers, to realise process solutions that meet their exact need. Whether customisation of standard equipment or full turnkey automated machinery is required Weldlogic has the answer.

Filter products and services

-

Seamer Elevated Riser Blocks

Seamer Elevated Riser Blocks supplied by Weldlogic Europe LtdRequest a Quote Supplied by Weldlogic Europe Ltd -

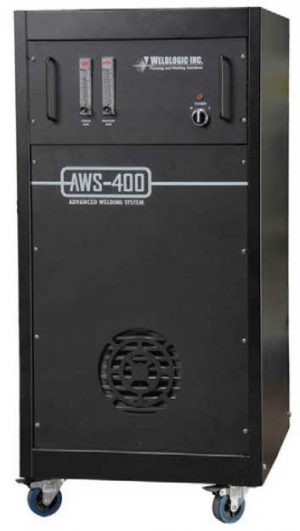

Specialized Welding Station

Specialized Welding Station supplied by Weldlogic Europe LtdRequest a Quote Supplied by Weldlogic Europe Ltd -

Square Tank Manufacturing Line Sheet Metal De-Stacker, 5 Axis Specialized C.N.C. Plate Roll, Transfer Cart & Elevated Seam Welder with Catwalk

Square Tank Manufacturing Line Sheet Metal De-Stacker, 5 Axis Specialized C.N.C. Plate Roll, Transfer Cart & Elevated Seam Welder with Catwalk supplied by Weldlogic Europe LtdRequest a Quote Supplied by Weldlogic Europe Ltd -

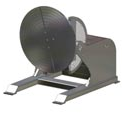

Table top Vertical Lathe Welding System

Table top Vertical Lathe Welding System supplied by Weldlogic Europe LtdRequest a Quote Supplied by Weldlogic Europe Ltd -

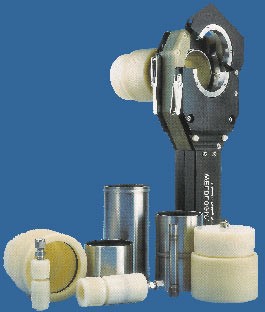

Tube alignment clamps

Tube alignment clamps supplied by Weldlogic Europe LtdRequest a Quote Supplied by Weldlogic Europe Ltd -

Tube alignment clamps

Welding tube alignment clampManual welders find it irritating and difficult to align pipes prior to welding. Achieving the perfect abutment is difficult using conventional manual techniques. These problems inevitably waste time and increase costs during the manufacturing process. Weldlogic have developed a range of internal tube alignment clamps to provide concentric alignment plus the added advantage of backing gas.Request a Quote Supplied by Weldlogic Europe Ltd -

Tungsten welding electrodes 1.5% Lanthanated - Gold

Most commonly used non-radioactive tungsten. Offers long electrode life under heavy or pulsing amperage loads. It has the ability to resist thermal shock which provides the user with excellent ignition with a lower burn off rate. Wide range of sizes.Request a Quote Supplied by Weldlogic Europe Ltd -

Tungsten welding electrodes 2% Ceriated Grey (Non-Radioactive)

Recommended for short welding cycles on low-amp, DC orbital tube, pipe, thin sheet and small part applications. Provides low current and arc ignition with good arc stability. This tungsten is not recommended for higher applications. The oxides that are contained tend to migrate very quickly to the heat at the tip of the electrode. Wide range of sizes.Request a Quote Supplied by Weldlogic Europe Ltd -

Tungsten welding electrodes 2% Lanthanated - Blue (Non-Radioactive)

Most commonly used non-radioactive tungsten. Offers long electrode life under heavy or pulsing amperage loads. It has the ability to resist thermal shock which provides the user with excellent ignition with a lower burn off rate. Wide range of sizes.Request a Quote Supplied by Weldlogic Europe Ltd -

Tungsten welding electrodes 2% Thoriated Red

This tungsten is used primarily in DC welding. It has a low work function and provides a high load and amperage capability. The health safety issue of 2% Thoriated tungsten has recently raised concerns regarding inhalation and disposal of the Thorium. Wide range of sizes.Request a Quote Supplied by Weldlogic Europe Ltd