Weldlogic Europe Ltd

For over 25 years Weldlogic has lead the market with innovations in micro-TIG and micro-Plasma welding. Its range of state of the art Linear and Computerised power sources are capable of delivering precise current, voltage and travel over programmable weld schedules. Along side these power sources are a range of welding lathes, turntables and linear seam welders. The company’s philosophy is to work in close partnership with its customers, to realise process solutions that meet their exact need. Whether customisation of standard equipment or full turnkey automated machinery is required Weldlogic has the answer.

Filter products and services

-

OM-5 Weld Check Oxygen Monitor

OM-5 Weld Check Oxygen Monitor supplied by Weldlogic Europe LtdRequest a Quote Supplied by Weldlogic Europe Ltd -

Oxygen Analyser for Weld Gas

The OM10 is the state of the art, easy to use Oxygen Monitor for weld gas.It has an extremely fast response and a very high accuracy. The analyser is the preferred standard for monitoring Oxygen in Arc welding gas, whether working with Stainless Steel, Duplex, Titanium or other high alloy steel. The OM10 achieves this without compromising on simplicity or sturdiness. To monitor the concentration of oxygen in argon and forming gas containing up to 10% hydrogen.

Request a Quote Supplied by Weldlogic Europe Ltd -

Oxygen Weld Purge Monitor

This Oxygen Weld Purge Monitor is designed specifically for the weld industry where the monitoring of purge gasses is important. Oxygen analyser for welding. It is a microprocessor - controlled, battery powered portable oxygen monitoring device. This acts as a perfect Weld Checker. Oxygen purge meter for welding. It is highly robust and is designed to be used in an industrial environment. The monitor facilitates continuous measurement of the oxygen content of the back-shield gasses during the entire purging and welding process. Oxidation of the weld root can thus be prevented.Request a Quote Supplied by Weldlogic Europe Ltd -

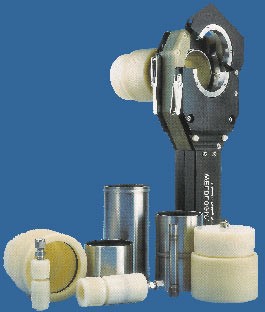

PA-10/100 STD 6100 System

PA-10/100 STD 6100 System supplied by Weldlogic Europe LtdRequest a Quote Supplied by Weldlogic Europe Ltd -

Piranha III Tungsten Welding Electrode Grinder

Piranha III Tungsten Grinder. This grinder is designed for maximum commercial use and includes a universal collet which will grind from .040.-3/16. The construction of the PIII unit is heavy solid steel and very user friendly. The Piranha III unit is also fully enclosed with a 90% containment of excess tungsten electrode dust. (20" x 12" x 12" - 51 lbs / 508mm x 304.8mm x 304.8mm - 23.13 kg) - Continuous grinding of .040" - 3/16" (1.0 - 4.8mm) tungsten. Solid construction. No vibration. - Longitudinal grinding for maximum arc stability. - Precision scale for setup and repeatability. - Electrode guide accommodates 6 electrode sizes. - Capable of a wide range of included angles. - Electrode notching station for simple cut-off. - Electrode guide has square end grind position. - Detailed Manual includes engineering data and welding recommendations. - 6.0" diamond wheel improves your surface finish - Vacuum port readyRequest a Quote Supplied by Weldlogic Europe Ltd -

Piranha II Tungsten Welding Electrode Grinder

Piranha II tungsten grinder. This grinder is ideal for general shop usage. Ideal for 1-3 welders. It includes a universal collet, which will grind from .040-3/32. This unit is fully enclosed and will contain excess tungsten dust. (12" x 8" x 8" - 14 lbs / 304.8mm x 203.2mm x 203.2mm - 6.35kg) - Easy set-up, optimal consistency and near-perfect repeatability. - Compact, durable and solid design with no vibration. - Longitudinal 20 RA grinding for maximum arc starting, arc stability, electrode life and weld penetration. - Universal collet arm for 3 electrode sizes - 040" (1.0mm), 1/16" (1.6mm), 3/32" (2.4mm) - with no equipment changes. - Included angle scale for angles from 10º - 60º Precision tip flat gauge & depth adjustment stop ensures exact tungsten points every time - enabling consistent, repeatable arc performance and welding output. - Containment baffle to keep dust inside the grinder housing, for safety and easy disposal. - Electrode notching station for simple cut-off. - Double-sided grinding wheel for maximum wheel life and value. - Detailed manual for valuable engineering data and welding recommendations.Request a Quote Supplied by Weldlogic Europe Ltd -

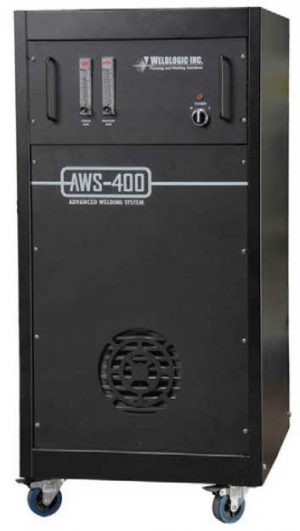

Plasma Welding Console

The PT-10 plasma welding console adds the capability of plasma welding to all Weldlogic TIG power supplies. Idea for Micro Arc plasma applications with the PA 10/100 or higher current needs to 400 amperes using the AWS controller or even for specialty key hole plasma applications the PT -10 expands your welding potential. Features include three levels of pilot arc settings a on and off switch, a built in water recirculator and heat exchanger and flow and temperature alarms with precision gas flow meter.Request a Quote Supplied by Weldlogic Europe Ltd -

PLS-180 Longitudinal Seam Welder

PLS-180 Longitudinal Seam Welder supplied by Weldlogic Europe LtdRequest a Quote Supplied by Weldlogic Europe Ltd -

PLS-240 20 Foot Longitudinal Seam Welder Weld Process Sub-Arc/Weld-Vision System

PLS-240 20 Foot Longitudinal Seam Welder Weld Process Sub-Arc/Weld-Vision System supplied by Weldlogic Europe LtdRequest a Quote Supplied by Weldlogic Europe Ltd -

PLS-24 Automatic Seam Welder

PLS-24 Automatic Seam Welder supplied by Weldlogic Europe LtdRequest a Quote Supplied by Weldlogic Europe Ltd