Telesis Marking Systems tyden group

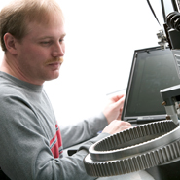

We are the worldwide leaders in the manufacture and development of Permanent Product Marking Equipment. The extensive range of programmable Laser Marking Machines, Pinstamp®(Dot-Peen) and Telescribe® Marking Systems are both fast, versatile and reliable and give asafe, permanent andprofessional result. Telesis Pinstamps® mark dot matrix or continuous line characters, even logos, graphics or 2-D Codes, on a wide range of materials from soft plastics to hardened steel and our range of Laser Equipment (diode-pumped solid state, CO2 and fibre) can similarly mark virtually any material with text, barcodes, logos, graphics and 2-D codes, so covering all Product Identification and Traceability requirements.

In an industrial environment, various components must be marked prior to, during and after production so that they can be identified and traced throughout their entire life cycle. Telesis Marking Equipment is used in thousands of manufacturing environments every day, throughout the world, in a wide variety of industries including Aerospace/Aviation, Automotive, Electronics, Heavy Equipment, Industrial, Medical, Oil/Energy and Packaging.

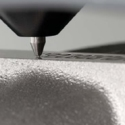

Pinstamp® Dot Peen Marking Systems

Fully programmable PINSTAMP® Single and Multi-Pin Marking Systems are based on Telesis' original, patented "Floating Pin" design. A pneumatically driven and returned metal pin permanently indents the marking surface with either dot matrix or continuous line characters - even logos, graphics or 2-D Codes*. Since the marking pin "floats" on constant return air pressure, surface irregularities up to 1/4" are easily accommodated. And, no stress concentrations occur.

Since the force of the mark is controlled by air pressure, product marking can be "customized" to suit most any application. Telesis manufactures over 10 versatile PINSTAMP® Models. They are cost-effective in a wide range of stand alone or on-line manufacturing situations.

Telesis Laser Marking Systems - Overview

There is one company known not just for innovation and leadership in laser marking technology, but also for problem-solving prowess. Telesis was one of the first to apply fiber lasers for marking applications, and we now offer a wide range of laser systems for a multitude of marking and material processing applications.

At Telesis, we provide more than well-engineered laser marking system solutions, we give you the confidence that you're going with the best. Telesis brings several advantages to laser marking applications.

Years of experience in industrial marking applications. While some firms may manufacture a capable laser, it needs to work in the real world. At Telesis, we have spent decades implementing Pinstamp® pin-marking solutions for the automotive, aerospace and other demanding industries. This background assures that our systems are durable enough to withstand hostile environments. Telesis laser marking systems don't just work in the lab, they work reliably day after day on production lines.

Broad range of technologies. Telesis offers a broad range of laser marking solutions. By working with all major laser marking technology platforms--fiber, solid state, and CO2 --we are able to meet your specific marking needs. We don't have to force-fit you into a predefined solution based on a limited product range.

Telesis Laser Enclosures

The ProStation “Complete Solution” Class 1 Laser Workstations features:

- Attractive, rugged fabricated sheet metal design

- Transverse laser head mounting for convenient loading and unloading

- Extruded aluminum floor for convenient attachment of work piece fixturing and parts handling accessories

- Work lamp and door interlock

- Keyboard and monitor arm

- Heavy Duty Manually Adjusted Laser Head Mounting Post OR Programmable Z-Axis Laser Head Mounting Post with 2-Axis Stepper Controller

- Tower Computer with 17” Flat Panel Monitor, Keyboard and Mouse

Other Enclosure Options Such As Those Pictured Below Also Available On Request.

TeleScribe® Scribe Marking Systems

TeleScribe® marking systems from Telesis Technologies are the preferred choice when low-noise marking is required. Sometimes called "drop and drag" or scratch marking, scribe marking is an established standard for VIN marking and other applications where the noise of a standard dot peen marker is a concern.

As a world leader in permanent marking, Telesis engineers TeleScribe® marking systems to accommodate the high mechanical stresses of the application while delivering optimum legibility of the marked part. All TeleScribe® systems utilize high quality rails and bearings to assure precise, repeatable pin positioning - ensuring consistent appearance of the mark from part to part.

BenchMark® Dot Peen Markers

BenchMark® dot-peen marking systems, proudly manufactured in the U.S. by Telesis Technologies, enable you to easily achieve quality, permanent part marking virtually anywhere you need it. Whether you have only an occasional need for marking, or if you need a marking capability in various locations, the BenchMark series is ideal.

All BenchMark systems are designed for easy set-up and immediate use, right out of the box. Since these systems are built on electromechanical pin designs, you can use these benchtop or handheld markers wherever you need them, unrestrained by the air supply lines competitors often use.

The fully-integrated but compact BenchMark controller does not require connection to a PC. This proven controller is a separate unit, allowing for easier maintenance and providing easy programming with broad functionality.

Identiplate® Data Plate Marking System

The fast, flexible DPP2000 automatically feeds and permanently marks metal data plates in a wide range of sizes and thicknesses. This fully programmable, table-top unit prints multiple character sizes from .03" to 4.00" (.76 - 101.6mm) on a single plate using Telesis' patented, low maintenance floating pin dot peen marking technology. Marking pattern design is quick and easy with the DPP2000's user- friendly software.

UID / Data Matrix Marking

Telesis Technologies is the leader in U.S. Department of Defense UID compliant permanent marking technology. Business Rule 14 of the UID Guide requires permanent Data Matrix markings on certain components supplied to the Department of Defense. TELESIS PINSTAMP® dot peen and LASER marking systems meet that requirement.

UID Basics

Our extensive experience in automotive, aerospace, firearms and other critical industries allows us to rapidly assess what is required to make your products UID compliant. Telesis trained Service Engineers can install and set up your marking, verification, and reading equipment as well as train your manufacturing personnel to insure a seamless transition to UID marking. Our systems can link with your factory data network to insure accurate, non-recurring serial numbers so that complete UID integrity can be maintained.

Manufacturers are increasingly turning to the use of 2-D code direct part marking (DPM) and reading technologies. DPM utilizing dot peen markers or laser markers reduces costs, improves quality, and satisfies a number of industry-specific and government mandates, including U.S. Department of Defense UID (Unique Identification) requirements. Successful implementation requires the integration of robust, industrial marking systems with 2-D code verifiers located at the marking station. Together, they insure the ability to easily read and track the 2-D code.

2D Code Markers

Telesis, the world leader in direct part marking of 2-D codes, offers two different permanent marking system technologies to satisfy a wide range of applications.

PINSTAMP® Dot Peen Markers provide an effective but extremely economical solution to many 2-D code DPM (Direct Part Marking) applications on materials as diverse as plastics and hardened steel. Telesis' patented PINSTAMP® Marking Technology provides highly accurate dot placement at specific X/Y locations. This process makes PINSTAMP® Markers far superior to conventional "oscillating stylus" dot peen markers, especially in 2-D code applications, where accurately marked codes are the key to readability.

TELESIS Laser Markers are truly "state-of-the-art", producing almost perfectly formed 2-D codes nearly instantly on a wide range of materials, including virtually all plastics and metals. These qualities make TELESIS Lasers the perfect choice for applications requiring extremely high throughput or very small 2-D codes.

Each of these technologies, PINSTAMP® Dot Peen Markers and TELESIS Laser Marking Systems, has its own relative merits in regards to 2-D code marking applications. A list of these relative merits is as follows:

Marking Technologies (Pinstamp)®/Dot-Peen v Laser)

- Laser Marking Systems, including TELESIS LASERS, normally provide a more precise mark than a PINSTAMP® marker, or any other dot peen marker. Since the precision of the mark is an important factor in machine readability, this results in better readability for laser marking in certain applications.

- PINSTAMP® dot peen markers cost considerably less than laser markers. PINSTAMP® markers typically cost $8,000-$20,000; laser markers are more commonly priced in the $50,000-$70,000 range.

- PINSTAMP® and all other dot peen markers imprint a round dot; whereas a laser marker is capable of marking a square cell. This adds to the relative readability of laser marks in 2-D applications, since a theoretically perfect Data Matrix® 2-D code is based on square cells.

- A PINSTAMP® marker utilizes much smaller components than a laser marker, making it easier and less costly to integrate.

- A laser marker is almost always much faster than a PINSTAMP® or any other dot peen marker. For instance, the time to imprint a 10x10 2-D code with a PINSTAMP® Marker is typically in the range of 2.5 - 5 seconds; with a laser it's more on the order of ½ second.

- Dot peen marks are widely accepted by the aerospace industry for marking critical parts; laser markers are typically not. The cross-section of a PINSTAMP® "crater" (dot) has no sharp corners, only gentle curves, resulting in no significant stress concentration. Laser marking can adversely affect material properties in the heat-affected zone of the mark, which can potentially result in the propagation of cracks in certain materials.

- PINSTAMP® marks are by nature low contrast marks, which depend solely on illumination techniques to create the contrast required for marking. On the other hand, in certain applications, laser marks produce higher contrast, which tends to add to their readability.

-

Direct part marking of machine-readable 2-D codes provides "cradle-to-grave" traceability, improving manufacturing efficiency, quality control, and inventory management. In addition, it satisfies a number of industry-specific and government mandates, including U.S. Department of Defense UID (Unique Identification) requirements. The process involves three key stages:

- Permanent marking of the code utilizing a dot peen marker or laser marker

- Verifying the readability of the code

- Reading the code at various times during the manufacture and/or life of the part.

New Cost-Effective EVC Diode Pumped Solid State Laser

The new EVC Laser aimed towards customers who want a low-priced and highly efficient marking solution. The EVC outstanding beam quality is ideal for marking linear and 2D bar codes, text, vectors, bitmaps and more on most metals, coated materials and some plastics.

We offer a package price of £14,990 for an EVC in a Compact Class 1 Bench Top Enclosure as shown below (£15,990 including PC). Other options including Marking On The Fly (MOTF), Powered Toolpost, Focus-Finder Diode and Fume Extraction System can be quoted on request.

Laser Marking Machines

Telesis offers a full range of laser marking systems capable of satisfying even the most demanding laser marking applications. Manufacturers of a wide range of products, from medical devices and instruments to automotive components, delicate plastics, ceramics, glass and aircraft components can mark virtually any material with text, barcodes, 2D codes, logos and graphics. At the cutting edge of technology, Telesis now offers optional “mark-on-the-fly” capable versions of all our standard laser systems.

We offer a full range of laser technologies – Diode-Pumped Solid State, Fiber and CO2.

Our E-Series Diode-Pumped, air-cooled lasers can operate in the harshest of environments whilst maintaining peak performance for many thousands of hours of maintenance free operation. In addition, they offer superior beam characteristics that make them uniquely capable among near IR lasers for many difficult applications, such as marking high resolution graphics, fine text or 2-D codes as well as marking many heat sensitive materials and components. The versatile E-Series is a broad family which includes the EV10DS, EV15DS, EV25DS and EV40 as well as the EV4G Green Laser, the choice for many electronic components as well as a wide variety of plastics, and the new EVC aimed at customers looking for a low-priced and highly efficient marking solution.

With our F-Series Fiber Lasers, we were the pioneer and continue to be the leader in Fiber Laser marking technology. These markers offer low maintenance marking of almost all metals at an affordable price. The F-Series includes three different models – FQ10, FQ20 and FQ30 for applications where faster process speeds are required.

The C-Series of CO2 Lasers are ideal for marking organic materials such as glass, perspex, plastics and acrylics, wood, leather vinyl and rubber. The series includes five different models – CO10A , CO30A and the most powerful CO60, with the CO10AP and CO30AP Mark On The Fly versions developed for packaging applications.

Pattern design for any of our lasers is easy with the Telesis designed MERLIN® II LS Software. This extremely user-friendly software runs on the Windows®2000, Windows® XP, Windows® Vista and Windows® 7 Platforms. Our Automated Marking Interface (AMI) version of MERLIN® II LSaddresses the need for a safe, easy operator interface. It provides the operator with the capability to barcode scan to load patterns, load a picture of the part and fixture, and insert the marking data in the proper field all without the need of a keyboard – virtually mistake free.

Telesis offers a wide variety of standard Class 1 and Class 4 laser marker enclosure styles including our ProStation “Complete Solution” Enclosure Package. When the situation demands it, our experienced custom engineering staff can design one to fit the specific needs of your application.

Telesis can also provide a complete solution to your laser marking requirements with parts handling accessories such as X/Y tables, rotary fixtures, rotary tables and manual and automated Z-axes.

ALL Telesis systems – whether standard or custom engineered – are backed by a global network of knowledgable Sales and Service Professionals.

New Telesis Electric Marker TMP4500/470E

The new TMP4500E is an extremely robust hand-held marking head with a powerful all new electric marking pin design.

With marking window 25 x 100mm it is perfect for portable applications which require deep marking, up to 0.46mm deep in mild steel.

It is teamed with the state-of-the-art self contained TMC470 Controller.

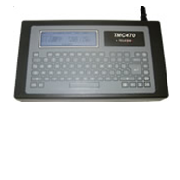

Telesis TMC470 Marking System Controller

Telesis TMC470 Marking System Controller Features:

- Fully self-contained – no PC required

- Easy-to-use menu design for pattern design and access

- Ethernet port for TCP/IP communications (not available on TMC420 version)

- Durable membrane keyboard

- Pattern backup via USB port (not available in previous TMC420 version)

- Stores up to 200 marking patterns locally

- One RS232/485 and one RS232 serial port and discrete I/O capabilities with spare I/O available for customer-specific needs (TMC420 version only has RS232/485 port)

- Optional internal board to control third and fourth axis (Z and rotary) – no separate driver required

- Optional panel-mount kit for panel mounting in NEMA/IP rated enclosures

- Confirms to all European Community (CE) norms

Controller Upgrade Programmes are currently available from previous TMC090 and TMC420 versions – please ask for details .

Find us on Google

We can be found on google.co.uk