Essex Laser Job Shop Ltd

Here at Essex Laser Job Shop, since 1998, we specialise in laser cutting and forming using an assortment of laser cutting machines. Our laser cutting and forming machines can handle any capacity from single parts to volume production. We use materials including stainless steel, brass and plastics. We also run a 160-ton pressbrake for all of your sheet metal folding requirements.

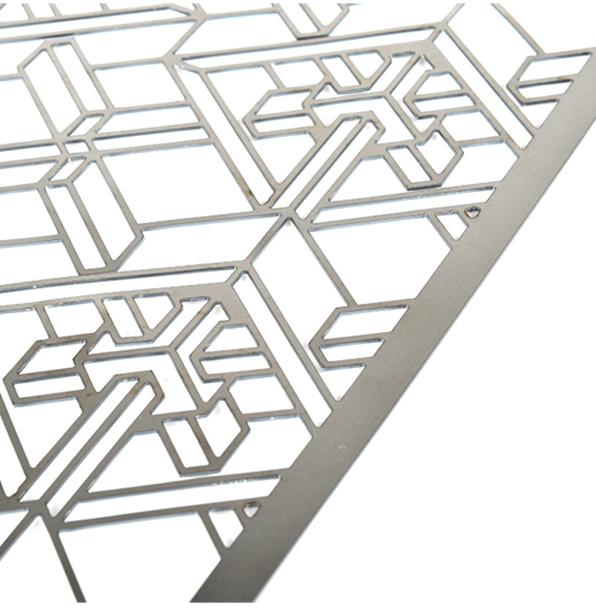

Laser Cutting

We have a great deal of laser cutting experience and pride ourselves in providing complete customer satisfaction. We provide laser cutting on a broad range of materials for clients in London, the South East and nationwide.

Precision Laser Cutting

We provide precision laser cutting using three high-powered, flat bed CO2 lasers especially for profile cutting, sub-contract work. Our precision laser cutting facilities range in power up to 5kw and bed size up to 4000x2000mm. We have first-class facilities for deburring and vibratory finishing.

Laser Cutting Capacity

We have an impressive laser cutting capacity enabling us to profile a broad range of materials. We have a variety of different laser cutting machines. We manufacture batch sizes from individual parts to several thousand with prototyping to volume production with a fast turn around or monthly call offs.

Sheet Metal Folding

We cater for all of your sheet metal folding requirements using our brand new 160 Ton Pressbrake machine. We are able to provide sheet metal folding up to 4000mm to match our laser bed size of 4000 x 2000mm. We will deliver parts directly to your premises, laser cut, and already formed.

Laser Cutting Services

We provide advanced laser cutting services on a variety of materials using our collection of laser cutting machines. Our professional laser cutting services enable us to cater for any size project, quickly, efficiently and at affordable prices.

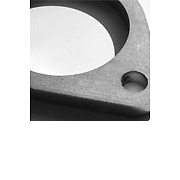

Waterjet Cutting

Dynamic Waterjet Cutting for all materials using the latest machines. Phone us on 01708 689658 for more information.

We now have a 4 x 2m dynamic head Waterjet. This Waterjet cutter was the first in the countrya and has a high-pressure direct-drive pump. At 4100 bar (60,000 psi), the dynamic Waterjet cutter cuts through virtually any material and the direct drive means means its quicker and cheaper.

Other features are dynamic cutting, where the Waterjet cutter changes the angle of the head to give the fastest cut around corners whilst keeping the cut edge square. The accuracy of the cut depends on the thickness of the material, but the general tolerance is +/- 0.2mm for premium quality.

Waterjet cutting has advantages over other cutting processes:

- Waterjet vs. Laser cutting - Waterjet cutting can cut almost any material and it cuts thicker materials than a laser cutter can i.e. up to 150mm thick. Also there is no Heat Affected Zone (HAZ).

- Waterjet vs. Plasma/Gas cutting - accuracy is greater with Waterjet cutting and the cut quality is better.

- Waterjet vs. Machining Because a Waterjet cutter is very fast the process works out cheaper but on the downside it's not as accurate as machining. We can “rough out” parts on the Waterjet and for high accuracy they can be CNC machined later. This method means that the part is almost complete and only a small amount of additional machining is required which helps reduce the cost of each part dramatically.