Container replacement system for automated material flows

30 August 2022Task

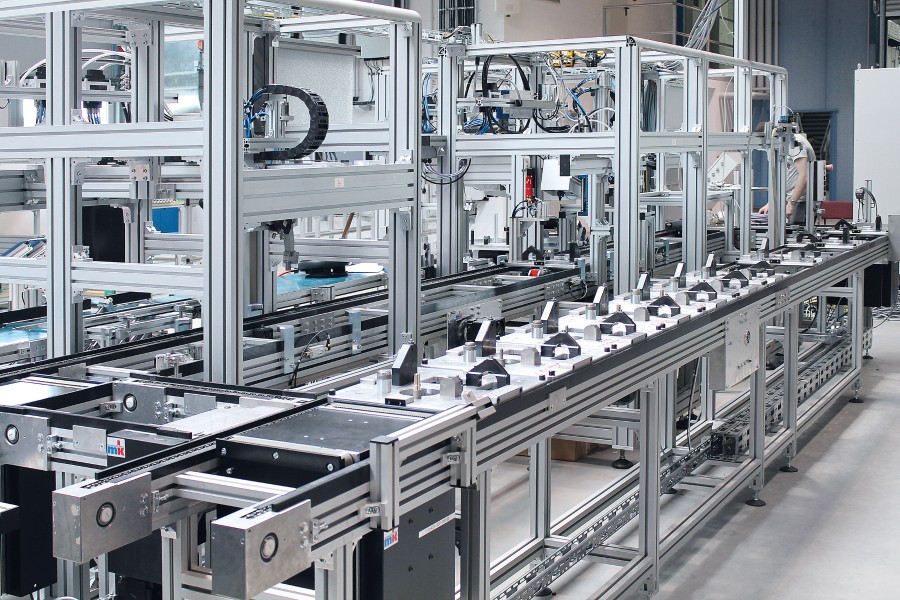

An automotive supplier for lighting technology and electronics requires further automation of its existing processes to keep its location competitive for the future. The customer wishes to improve the flow of materials at the injection moulding machines to allow for more efficient and flexible use of the machines. Small load carriers (SLC) containing multi-layer workpiece holders must be supplied to a robot workstation, filled and then removed again by a space-saving solution. To be filled by the robot, the containers must be positioned exactly and stopped without damaging the sensitive workpieces. In addition, it must be possible to buffer several SLCs so that this process can run independently for a period of time.

Solution from MK

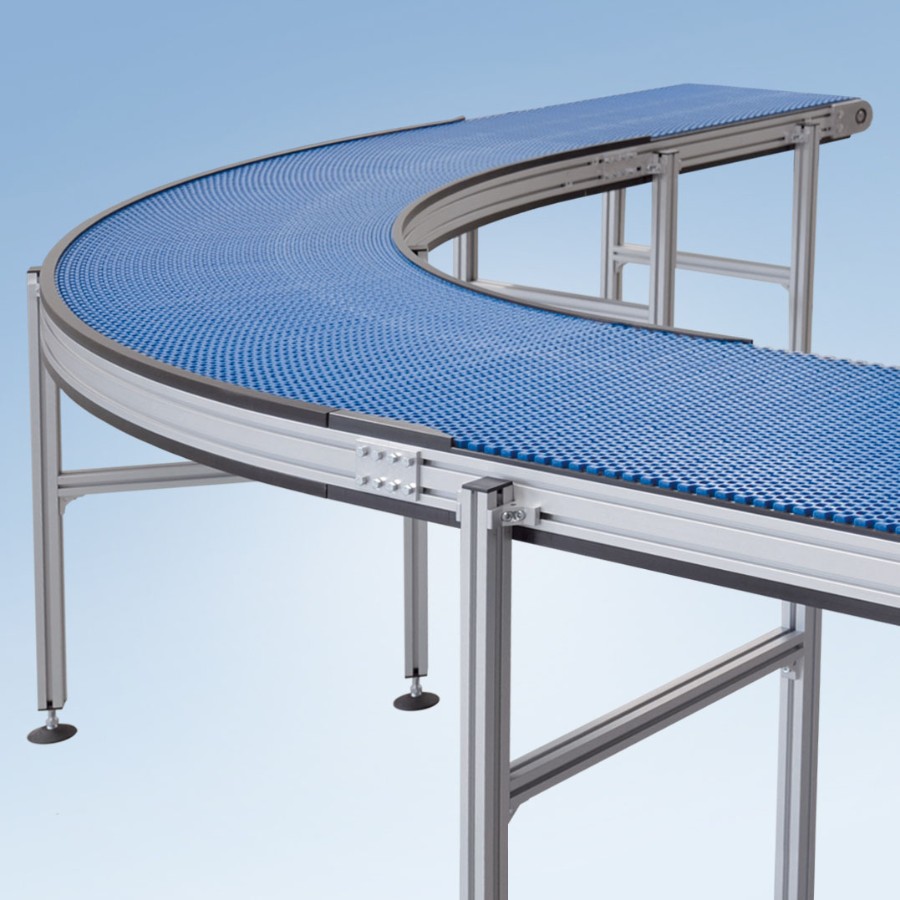

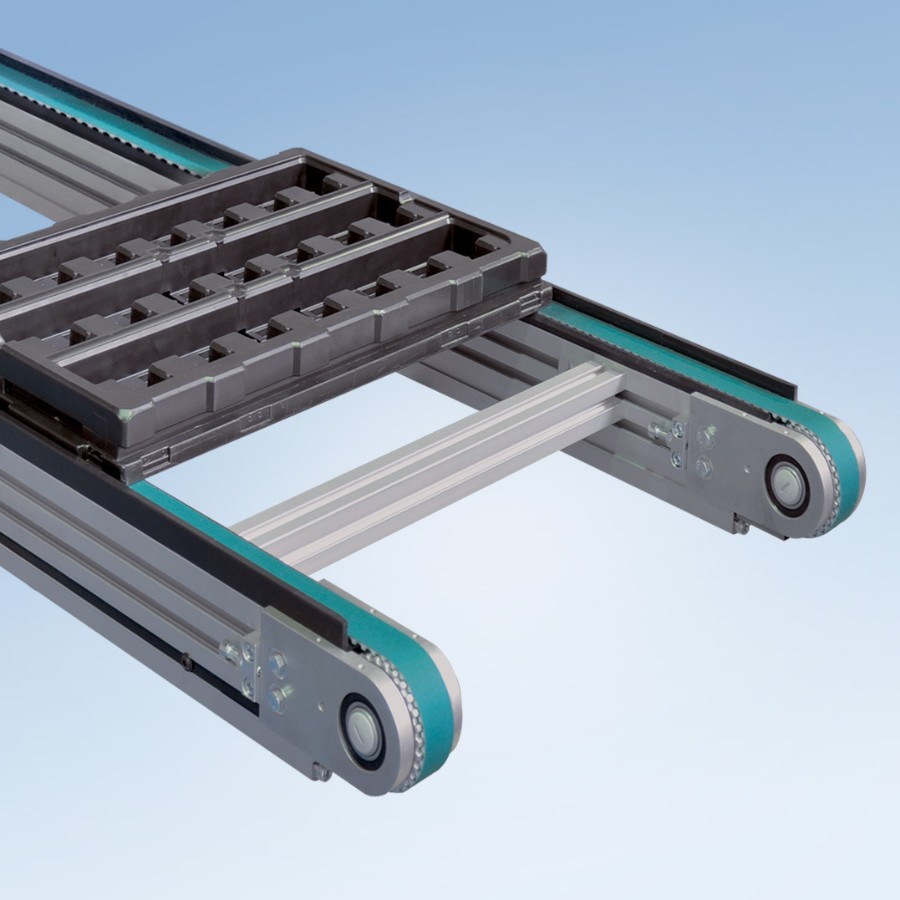

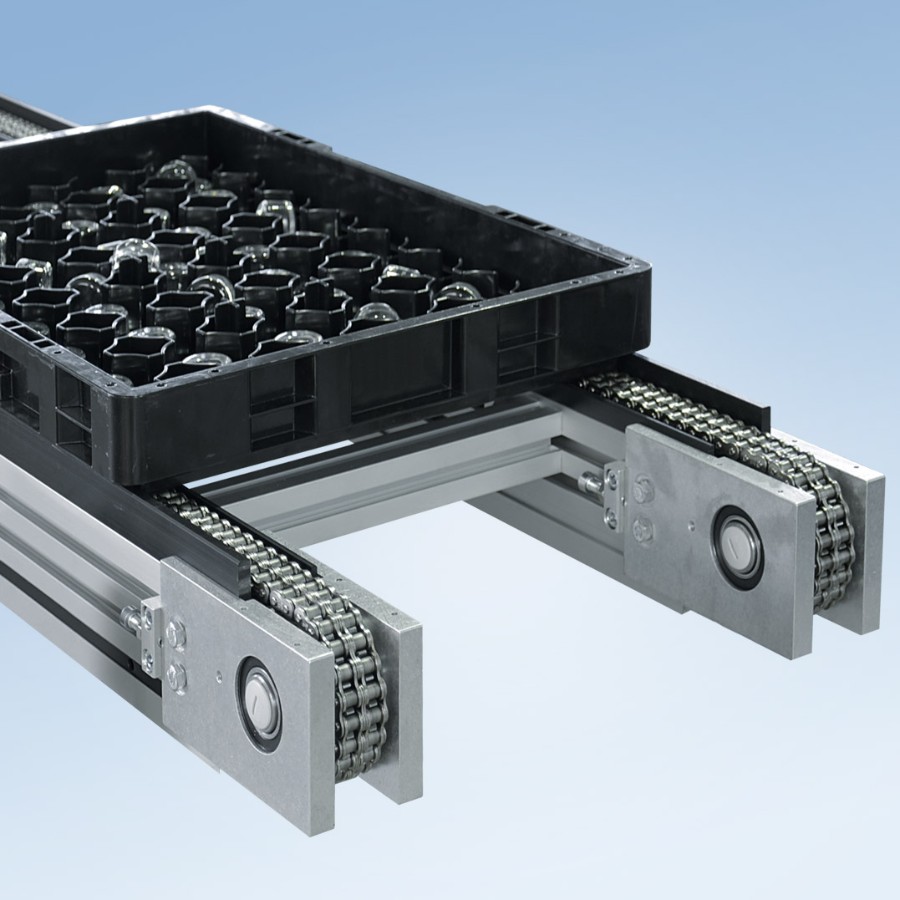

MK designed several compact container replacement systems to meet these requirements. A frame made of Series 40 aluminium profiles contains GUF-P 2000 belt conveyors located on two levels, connected by short lifts. The empty SLCs are fed to the robot on the upper level. There they are separated and centred so that the robot can position the workpiece holders and intermediate layers in the containers, as well as the workpieces themselves. The filled SLCs are lowered by the short lift to the lower level, where they are removed from the workstation and stopped at the end of the conveyor without any shocks to the workpieces. The system has the capacity to buffer three containers per level. Since some injection moulding tools can mould different parts simultaneously, it is possible to place multiple conveyor lines next to each another and thus provide the robot with multiple SLCs in parallel. This allows you to separate the parts into different SLCs based on type.

Customer benefits

- Increased productivity

- Lower production costs

- Compact dimensions for small footprint

- Proven and durable technology

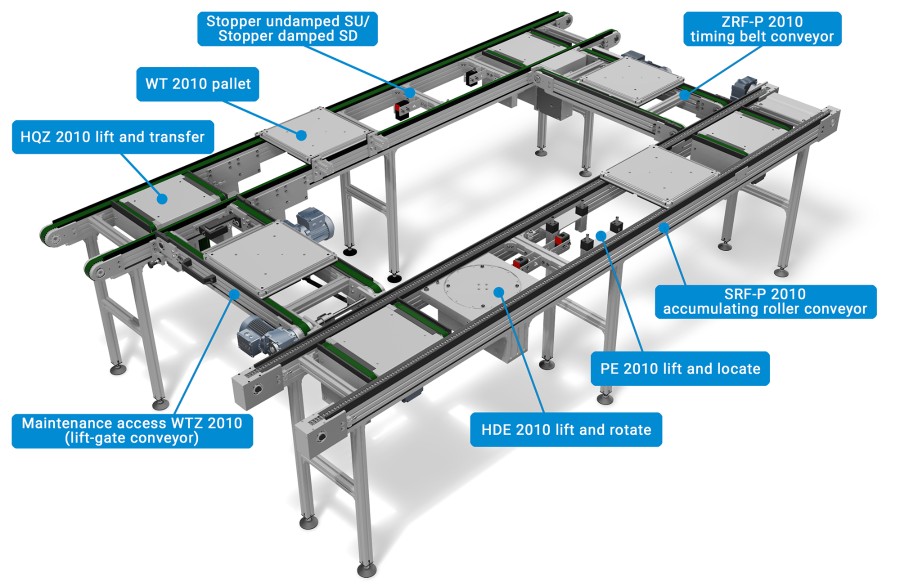

Products used