Embracing Sustainability: The Pros and Cons of Plastic Extrusion Products Made from Recycled Materials

12 April 2023ADVANTAGES OF USING RECYCLED MATERIALS IN PLASTIC EXTRUSION PRODUCTS

Environmental Impact: Utilising recycled materials reduces the demand for new raw materials, thereby conserving natural resources and reducing energy consumption. Moreover, recycling plastic waste prevents it from ending up in landfills or polluting oceans and other ecosystems.

Cost-Effectiveness: Incorporating recycled materials in the manufacturing process can often result in cost savings, as the price of recycled plastics tends to be lower than that of virgin materials. These savings can be passed on to consumers in the form of lower product costs.

Enhanced Brand Image: By using recycled materials, businesses can demonstrate their commitment to sustainability and environmental stewardship. This can lead to an enhanced brand image, attracting eco-conscious customers and fostering long-term customer loyalty.

Compliance with Regulations: As governments worldwide continue to tighten regulations surrounding waste management and environmental responsibility, using recycled materials in plastic extrusion products can help businesses stay compliant and avoid potential penalties.

DISADVANTAGES OF USING RECYCLED MATERIALS IN PLASTIC EXTRUSION PRODUCTS

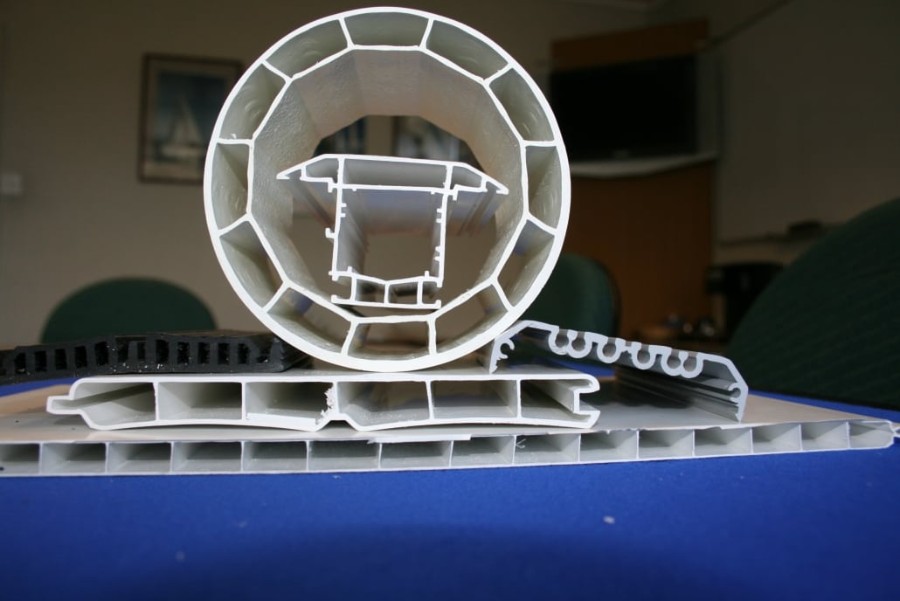

Quality Concerns: Recycled materials may contain impurities or have inconsistent properties, which can lead to variations in the finished product’s quality. If reprocessed materials are used to manufacture product there may be variations in colour/shade and shape of the profiles even if only a percentage mix is added to a virgin material. Using recycled material can also make the extrusion process difficult as it can cause variations in the profile’s size and shape which makes it impossible to keep within the specified tolerances. If the products need to look aesthetically pleasing, it is best not to use recycled material, but it may be possible to use a blend of material which may be acceptable.

Limited Material Availability: The supply of recycled plastics can sometimes be limited, depending on market demand and recycling infrastructure. This may result in supply chain disruptions or difficulties sourcing specific recycled materials. D W Plastics recycles most of its scrap material on site which is used in some products or sent away for further reprocessing. However, the quantities are not sufficient to be able to manufacture large volumes of product.

Higher Processing Costs: While the cost of recycled materials may be lower, the processing required to make them suitable for use in plastic extrusion products can be more complex and costly. This includes cleaning, sorting, and reprocessing the materials to meet the desired specifications.

Conclusion

At D W Plastics Ltd, we believe in striking a balance between environmental sustainability and product quality. While there are some disadvantages to using recycled materials in certain plastic extrusion products, the benefits often outweigh the drawbacks. By partnering with us, you can be confident in the quality and sustainability of the plastic extrusion products you purchase.