HEMCO Power and Control Systems Ltd

Founded in 1963, HEMCO ( Hants Electrical Manufacturing COmpany ) now has more than 60 years of experience in designing and building electrical control systems for a wide variety of process control, machinery and manufacturing applications. In that time we have successfully completed projects for a diverse range of industry sectors, with applications as varied as drawing wire, winding cable, extruding plastics, mixing food, handling components, pumping water or chemicals, and controlling temperature. We specialise in all levels of design and manufacture, from simple panel building to complete integrated systems, whether from scratch, or according to customer designs.

Filter products and services

-

Military

HEMCO Power & Control Systems Ltd are able to offer suitable solutions to modern challenges, using our experience, built over many years.

Request a Quote Supplied by HEMCO Power and Control Systems Ltd -

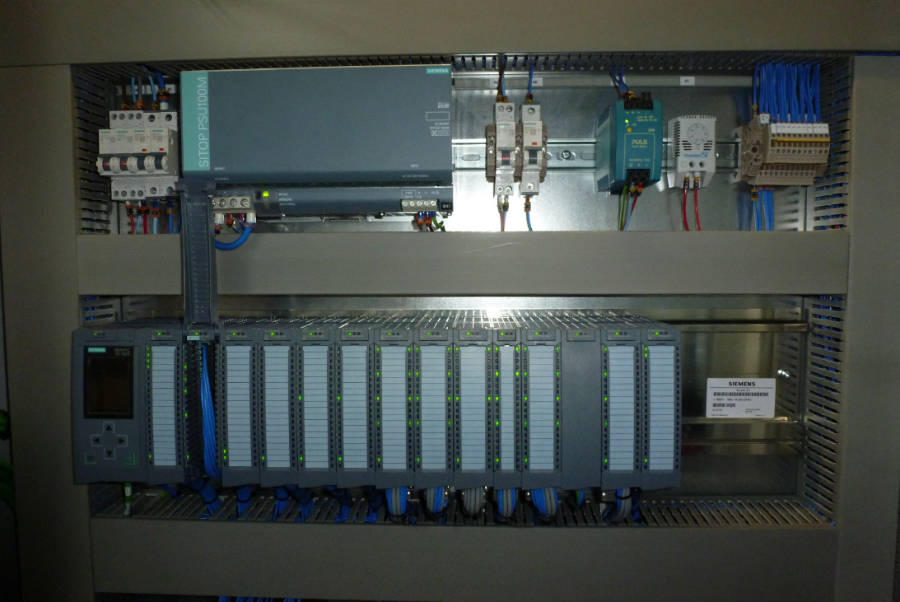

Panel Building - Electrical

Panel Building - Electrical supplied by Hemco Power and Control Systems Ltd -

Pharmaceutical

From initial design through to manufacture, installation, commissioning and servicing, HEMCO Power & Control Systems Ltd have a wealth of knowledge in the pharmaceutical arena that helps us deliver bespoke control system solutions to their meticulous processes.

Request a Quote Supplied by HEMCO Power and Control Systems Ltd -

Plastic & Metal Extrusion

From concept design through to manufacture, installation, commissioning and servicing, HEMCO Power & Control Systems Ltd have a wealth of knowledge of both Plastic & Metal extrusion technologies that helps us deliver bespoke control system solutions to these ever increasingly, challenging and demanding processes.

Request a Quote Supplied by HEMCO Power and Control Systems Ltd -

PLC's, HMI's & SCADA

Whether your requirement is a PLC, HMI or full SCADA application, software developed and written as a bespoke solution or a simple modification to an existing system, HEMCO Power & Control Systems Ltd can help. We’ve completed a variety of PLC, HMI & SCADA programming projects and have developed software for a wide variety of uses. From small projects with a small amount of I/O to large, complicated and extensive process Control Systems including full SCADA software

Request a Quote Supplied by HEMCO Power and Control Systems Ltd -

Process Control - Systems

Process Control - Systems supplied by Hemco Power and Control Systems Ltd -

Project Management

We have an established reputation for providing high quality project management services across both public and private sectors for over 50 years. Our depth of experience and extensive range of in-house skills enables us to efficiently evaluate potential projects, develop designs and specifications, then cost and deliver them. We are experts in the efficient delivery of multi-project programmes of work, via an integrated team with extensive experience in process plant equipment, electrical, mechanical, instrumentation, control, software, design and installation capable of providing intermittent working to fit with the process plant operational demands, without adding additional expenditure to projectsRequest a Quote Supplied by HEMCO Power and Control Systems Ltd -

SCADA - Systems

SCADA - Systems supplied by Hemco Power and Control Systems Ltd -

Software

With over 30 years' experience with SCADA & PLC systems, we have an industry leading background in delivering successful projects for most industry sectors, including Water Utilities, Power (Fossil/Nuclear), Process, Automotive, Aerospace, Food/FMCG, Logistics, Manufacturing & Petrochemical. Whether you have need of a new plant, requiring a large complex networked SCADA & PLC solution, or simple modifications to an existing legacy PLC or SCADA system, our experienced in-house software team will provide a successful projectRequest a Quote Supplied by HEMCO Power and Control Systems Ltd -

Support Services

Practically all plant and equipment requires periodic maintenance to some degree. When it comes to maintenance, there is no strategy to fit all situations. The 'Fire fighting' technique of lets fix it when it breaks may be the best option in some instances, however, in most cases it pays to be proactive rather than waiting for a piece of equipment to fail. We have experience with many maintenance techniques including preventive maintenance, predictive maintenance or condition based maintenance. We work with our clients to create a maintenance strategy that suits them. Our electrical workshop facilities allow us to manufacture, fabricate and repair at very short notice a wide cross section of plant and equipment for a wide range of industries. We also stock many everyday items and spare parts ranging from mechanical items such as fasteners and fixings, pipework and fittings and assorted steel work to electrical items including cables of all sizes and types and control panel/starter components such as overloads, contactors, timers, protective devices etc. Our success is due in no small part to our ability to complete our works quickly with minimal interruption to production and our workforce which span many engineering disciplines can be drawn in immediately to resolve large scale problems if required.Request a Quote Supplied by HEMCO Power and Control Systems Ltd