Introducing Perlast® G77X

2 April 2024PPE launches a new class-leading high temperature FFKM

Precision Polymer Engineering (PPE) has developed Perlast® G77X – a perfluoroelastomer (FFKM) sealing material combining high temperature performance with exceptional low compression set.

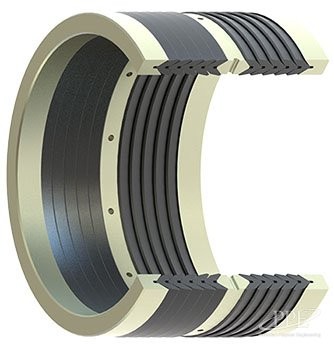

Perlast® G77X has been engineered for long term performance and durability in a range of critical applications, including chemical processing, aerospace, and in mechanical seals. The material can be moulded into O-rings and custom shapes.

Perlast® G77X is class-leading in high temperature capability, with long term performance and durability in temperatures up to a maximum of 350°C. Continuous temperature performance is also outstanding, with compression set testing at 330°C for 24h and 72h – better than many other key competitor materials in this space.

Other prominent features of Perlast® G77X are:

- Excellent response to temperature cycling effects

- Exceptionally low compression set over extended periods

- Excellent seal force retention properties

- Excellent mechanical properties

- Good chemical resistance

- Aerospace tested to AMS 7257 Rev E (QPL listed)

What are the benefits?

Upgrading to Perlast® G77X can have several advantages to an operator. There is marked improvement to sealing performance in high temperature applications, across a wide range of chemistries. Other benefits include:

- Extended maintenance intervals, or MTBR (Mean Time Between Repair)

- Increased safety margins

- Reduced cost of ownership

- More reliable performance in temperature cycling applications

Furthermore, Perlast® G77X has been tested externally to AMS 7257 Rev E, and the material will be listed on the PRI-QPL database, a compliance which is hugely significant to aerospace customers.

Perlast® FFKM – a material family when performance matters most

The development of Perlast® G77X brings the total number of Perlast perfluoroelastomers for the most critical applications to six. It means that PPE can now offer a high performance sealing option for extreme high and low temperature applications, all kinds of chemically aggressive operating environments, as well as food contact applications.

To discuss how Perlast® G77X could benefit your operations, get in touch with our industrial sealing specialists,

You can also request a free quotation, or to find out more, take a look at the Perlast® G77X video!