V and F Sheet Metal Co Ltd

V and F Sheet Metal are a UK Hampshire based sheet metal fabrication, sheet metal work and sub-contract engineering company. We provide sheet metal manufacturing services including CNC punching, CNC laser cutting, CNC bending, welding and press work. Using the latest CAD/CAM software modelling for the best accuracy and speed of sheet metal blank development for our in house CNC punching and CNC laser cutting processes. Supporting a wide range of industries in the UK from electronics to lighting, heating and audio.

Established in Fareham, Hampshire in 1985, with the ability to handle engineering projects from one off small batches of bespoke sheet metal work to high volume power press work V and F Sheet Metal are flexible enough to offer you the complete sub-contract sheet metal fabrication service for your growing company. Regular deliveries to Portsmouth, Southampton, Winchester, Eastleigh, Andover, Basingstoke and other towns in Hampshire from our factory in Fareham is easy. Over-night pallet and small package deliveries right across the UK for those who need it is offered to ease sheet metal component supply.

We have grown to a size where we can offer a complete sub-contract sheet metal fabrication and sheet metal work service to our customers right across the UK. This can include advice on the suitability of sheet metal work designs for manufacturing, sub-assembly work or sub-contract finishing and treatments to your specification e.g. zinc plating, alocrom 1200 / 1000, iridite NCP, surtec 650, silver and black anodising, powder coating, wet painting and screen printing. Continually investing in the latest CNC manufacturing equipment and CAD/CAM software enables us to offer the best combination of quality and price to suit your sub-contract engineering and sheet metal fabrication requirements.

We have a long history of working with UK based lighting companies to reduce their sheet metal fabrication costs and improve the quality of their sub-contract engineering/sheet metal work projects. With many standard CNC punching tools and material set-up costs can be kept to a minimum when considering new sheet metal fabrication projects.

- Sheet Metal Enclosures and sheet metal housings for the electronics industry

- Reflectors and sheet metal fabrications for the UK lighting industry

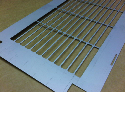

- Sheet Metal Perforated Ventilation and Speaker grilles for the heating and audio industries

- Front panel electronics and rack mount sheet metal work

- Welded assemblies - thin gauge to 6mm sheet metal fabrications in ferrous and non-ferrous materials

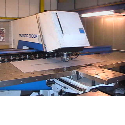

- CNC punching using Trumpf CNC punch presses

- CNC laser cutting with our Trumpf 3030 3KW fibre laser cutting machine

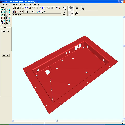

- CAD/CAM processes supported by Radan 3D and 2D software to aid CNC punching and laser cutting

- Sheet Metal CNC bending up to 3.0M long (7 press brakes), including 3 Trumpf 7036 CNC press brakes and a 3M Safan e-Brake CNC press brake

- Tig, Mig, Gas, Spot and Stud sheet metal fabrication welding capacity

- Power press sheet metal work up to 50 tons with custom press tools

Where can I get sheet metal work? Look no further if you are looking for CNC punching, CNC laser cutting, CNC bending and other sheet metal working processes:

For further information and to discuss your personal sheet metal project requirements call us on 01489 577786.

For more information about sheet metal please visit this page What is Sheet Metal Work and how is it made?

-

CNC punching is so versatile when it comes to sheet metal work

11 January 2019If it's CNC punching you are looking for then V and F Sheet Metal have that facility here and waiting for you. With 2 Trumpf CNC punch presses and a large range of CNC punch press tooling we can offer you the complete package.

http://www.vandf.co.uk/tooling/what-is-cnc-punching/

To investigate some of our past projects or request a quotation contact our website for more details.

-

Sheet metal assemblies manufactured in Great Britain in 2019

10 January 2019If you are looking to create sheet metal designs with more than one components you will need to use some method of assembly. It could be a permanent method such as spot welding or tack welding. It might be an assembly that you need to remove at a later stage and then pop riveting or screwing maybe the solution. We can help you decide what's best for your design and offer price breaks accordingly.

http://www.vandf.co.uk/blog/sheet-metal-assemblies-manufactured-in-great-britain-2019/

-

Where can I purchase sheet metal work in the UK?

8 January 2019Where can I purchase sheet metal work in the UK?

Well if you are looking for a small friendly family run sheet metal working company based on the south coast, V and F Sheet Metal are a great place to start. With well over 30 years experience in manufacturing sheet metal products and welded fabrications. Whether it's special projects or repeat batches we can support you. With the latest CNC laser cutting, CNC punching and CNC bending facilities in house we are very well equipped to take on most sheet metal projects.

http://www.vandf.co.uk/blog/where-can-i-purchase-sheet-metal-work-in-the-uk/

Contact us by phone or e-mail and our friendly engineering team will be happy to help you.

-

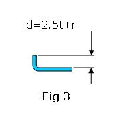

Folding sheet metal parts with bespoke CNC press brake tooling

7 January 2019Here's another great example of the versatility of our CNC press brake facility here at V and F Sheet Metal. We had a project that needed very small double bending in 1.2mm zintec. There was no way that standard air bend V blocks and blades could produce parts. We worked with Trumpf and their tooling team to come up with the perfect solution. For more details follow the link to our website ....

-

Sheet metal assemblies manufactured in the UK

3 January 2019Sheet metal assemblies manufactured in the UK to help improve your competitive advantage. No matter what type of assembly work you are looking for we will be happy to help you whether it's spot welding, tack welding or pop-riveting. Purchasing all our materials in the UK and manufacturing from our base in Fareham, Hampshire we are happy to help you with your design ideas and produce components at the right price and quality.

To get a quote right now in 2019 contact on 01489 577786 or e-mail us your drawings to sales@vandf.co.uk and our friendly engineering team will be happy to help you.

http://www.vandf.co.uk/blog/sheet-metal-assemblies-produced-to-your-design-in-the-uk/

-

Sheet metal fabrication subcontractors in Great Britain 2019

24 December 2018Sheet metal components, press work and welded assemblies manufactured in Hampshire, Great Britain.

Whether you can just a few components for a special project or new prototypes or perhaps repeat batch work give us a call on 01489 577786.

http://www.vandf.co.uk/blog/sheet-metal-fabrication-company-based-in-hampshire-great-britain/

For an in depth look at sheet metal work, manufacturing services and past projects take a look at our website www.vandf.co.uk

-

Sheet metal projects produced in December 2018

17 December 2018Well to round off the year I thought it would be nice to feature a few sheet metal projects produced in December 2018. To see all the wide range of sheet metal services we offer take a look at our company blog

http://www.vandf.co.uk/blog/sheet-metal-manufacturing-projects-produced-during-december-2018/

For an in depth look at plant and manufacturing techniques follow our blog and web pages carry hundreds of part project galleries.

-

Sheet metal production facility in Great Britain - 2019

13 December 2018Sub-contract sheet metal manufacturing facility ready to manufacture your products, 2019.

Using a wide range of manufacturing equipment and techniques to provide a helpful service. Using CNC laser cutting, CNC punching and CNC bending machines linked to the latest CAD/CAM sheet metal software to offer you a competitive service.

http://www.vandf.co.uk/blog/sheet-metal-production-in-great-britain-contact-vf-sheet-metal/

Contact us on 01489 577786 and have a chat with our engineering team or send your drawings to sales@vandf.co.uk and we will provide you with a range of price options for your latest sheet metal projects.

-

CNC punching aluminium panels in Great Britain

10 December 2018If you are looking for a sheet metal company in Great Britain who can produce your sheet metal panels contact V and F Sheet Metal. Where they are CNC punched or laser cut we will be able to help you. Full sheet nests using the latest Radan 2019 CAD/CAM software.

http://www.vandf.co.uk/blog/cnc-punching-aluminium-sheet-metal-panels/

-

Sheet metal components manufactured during 2018

6 December 2018V and F Sheet Metal, based in Hampshire Great Britain have been manufacturing sheet metal components for well over 30 years. Offering advice on sheet metal design to get the best from the latest CNC manufacturing methods and a wide range of plant they can offer the perfect service to small and medium sized companies.

http://www.vandf.co.uk/blog/sheet-metal-components-manufactured-in-great-britain/

For more information on the type of service they can offer you please take a look at their Applegate Profile page or go direct to their website, www.vandf.co.uk

-

Laser cutting 6mm mild steel brackets

4 December 2018V and F Sheet Metal are capable of helping you design your ideal bracket, laser cut or CNC punch, CNC bend and finish in any colour you want.

http://www.vandf.co.uk/blog/laser-cutting-6mm-thick-mild-steel-brackets-to-your-designs/

Whether it's 6mm thick mild steel hanging brackets as the image here , 2mm stainless steel pump mounting brackets or 0.7mm zintec lamp holder brackets we are definitely the people to contact. With over 30 years experience and a wealth of standard tooling we have an engineering team ready to help you with your designs and save you money in manufacturing.

-

Sheet metal workers based in Hampshire Great Britain

30 November 2018V and F Sheet Metal, a sub-contract sheet metal working company are based in Hampshire, Great Britain. We can help you with your sheet metal designs, improving parts for manufacturing to save you money again and again. We carry out all manufacturing processes in house including laser cutting, CNC punching, CNC bending, welding, press work and rolling sheet metal products.

Working with stainless steel, mild steel, aluminium, copper, brass and more obscure coated and reflector materials.

http://www.vandf.co.uk/blog/sheet-metal-workers-in-hampshire-great-britain/

Contact us at 01489 577786 or sales@vandf.co.uk with your sheet metal projects.

-

Sheet metal brackets help support British furniture building

15 November 2018V and F Sheet Metal are proud to have helped support a modern furniture manufacturer in Great Britain. A new range of furniture needed different mild steel brackets, CNC punched and CNC folded.

Take a look at the blog post below for more information on the sheet metal brackets and the furniture that it help make.

http://www.vandf.co.uk/blog/furniture-brackets-manufactured-from-sheet-metal-in-great-britain/

-

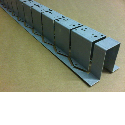

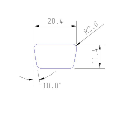

CNC press brakes to produce curved sheet metal work

12 November 2018If you don't want to buy tooling for you sheet metal project and you have designed a curved shape, multi-bending with a CNC press brake may be the answer.

Using a cleaver bit of CNC programming and the right combination of standard tooling V and F Sheet Metal can produce curved sections without the need for new tooling. By stepping a small amount for each bend a curve can be produced. This technique is ideal for small batches or trying out new designs.

For more information on this production technique please give us a call (01489 577786) and we will be happy to discuss your project further and investigate your options.

-

Sub-contract sheet metal manufacturing

5 November 2018There can be many advantages to using CNC sheet metal processes to aid manufacturing.

Firstly, the speed with which new projects can be prototyped and developed. Very often no special (new) tooling is needed whether components are going to be CNC punched or CNC folded. No tooling is required if sheet metal manufacturing is taking place with our Trumpf 3030 3KW fibre laser cutter. This allows us combine the correct set of skills and techniques to the products that you have designed.

If you are looking for a new sub-contract supplier in Great Britain for your CNC manufactured sheet metal working projects then please give our team a phone call on (01489 57776). If however you would prefer to e-mail us (sales@vandf.co.uk) there's no problem with that.

Make the move today and start to reap the benefits of working with a flexible and reliable sub-contract sheet metal supplier.

-

Quality sheet metal workers in Hampshire UK

22 October 2018V and F Sheet Metal have been manufacturing sheet metal products and assemblies for over 30 years. Supporting a wide range of companies across the UK from their base in Hampshire. With the very latest manufacturing equipment, software, tooling and ideas to help reduce your costs, improve your part quality and offer the support you need.

http://www.vandf.co.uk/blog/quality-sheet-metal-workers-in-hampshire/

Contact them on 01489 577786 to talk to their engineering team or e-mail sales@vandf.co.uk if you already have 3D or 2D data.

-

Laser cutting mild steel brackets with a Trumpf 3030

19 October 2018We have over 30 years of experience in manufacturing sheet metal brackets here at V and F Sheet Metal. Our production machinery is ideal for producing small sheet metal parts like brackets, angles, plates, panels, boxes etc. The picture you can see here was taken through the viewing port looking into our Trumpf 3030 3KW fibre laser cutting 3mm thick mild steel.

This machine can easily go from job to job with virtually no set up time. This example is laser cutting some small brackets from material off-cuts saved over from a previous job. With software off-line and at the laser machine we can update CNC programs from full production sheets to part sheets, ideal for urgent small batches of work.

To view additional examples of sheet metal brackets produced at V and F Sheet Metal why not view Bracket and Angle Gallery.

You can view a video of our laser cutter in action, follow the link.

So in conclusion, if you have a sheet metal bracket that needs producing give us a call on 01489 577786 or e-mail us your drawings to sales@vandf.co.uk

-

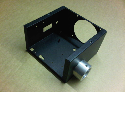

Sheet Metal Work From V and F Sheet Metal in Hampshire Great Britain

8 October 2018Every day we receive a variety of inquires, some large scale, others smaller. Whether you just need a few sheet metal prototypes for your new design or full production we are here to give you the help you need! We use the latest methods of CNC punching and laser cutting to produce accurate sheet metal blanks. Working with our range of CNC bending machines to produce work from the simplest single angle to complex electronics chassis components. In addition to this we offer in house welding facilities, all in all a comprehensive manufacturing service!

We have an expert team of trained sheet metal workers able to turn their hand to all sorts of projects. From welding aluminium housings, folding stainless steel enclosures, laser cutting brass and copper electrical components. You come up with it and we've seen it before!

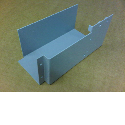

The image shown here is a CNC punched zintec treated mild steel bracket. Using a particularly clever piece of tooling on our Trumpf 3000R we were able to produce the folded flaps at the same time as punching. The Trumpf multi-bend tooling works with a range of materials and thicknesses. It saves a lot of time and produces a very consistent bend.

So it's down to you now. Give us a call today if you have a project and you want some advice and information on prices. We are always happy to look at current parts and offer valuable advice to help save you money. Perhaps we can manufacture your component using a different process which could potentially improve quality and save you some money. Contact us on 01489 577786 or sales@vandf.co.uk.

-

Laser cut components with a protective plastic film

27 September 2018Laser cut stainless steel

This week our Trumpf 3030 3KW fiber laser has been going great guns, hardly stopping between jobs! The latest interesting project involved producing a batch of 300 laser cut brackets using stainless steel of 2mm gauge with a 4 thou plastic fiber laser coating.

We are able to offer you a complete laser cutting service from 3D modelling, CAD/CAM program development, laser cutting and down stream production processes. Using Radan 2017 sheet metal CAD/CAM software we take your 3D data in the form of STEP or SAT files. 2D drawings can also be acceptable of PDF files and we will calculate the correct developed blank sizes for you. Using advanced nesting algorithms we can experiment with different nesting patterns to produce the most parts from any given sheet. This technique helps to reduce costs at the quoting stage and speeds up production cutting times.

If you have a project that needs some input from a friendly sheet metal company then we are here to help. We can look at your designs and suggest areas that can be improved with a view to saving you money. Always a great start! Just send us your drawings to sales@vandf.co.uk and we will be happy to take a look for you.

Would you like to see more images of laser cut components to give you some ideas for your design? Take a look here: Pinterest Board We have many examples of our work on our Pinterest Boards and gallery pages within our website.

If you are interested in a more detailed description of the production of this component, please read our blog post :

http://www.vandf.co.uk/blog/laser-cut-stainless-steel-plates-with-a-protective-plastic-film/

-

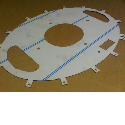

Laser cutting stainless steel components

26 September 2018You wouldn't believe it but I actually enjoy talking about our ability to produce complex pieces of metal work using our Trumpf fiber laser cutter! This intricate component is a great example of a really complex inner and outer profile. With the high number of curves this sophisticated shape is an ideal candidate for laser cutting.

Whether you are looking to just have a few stainless steel parts laser cut or higher volumes here at V and F Sheet Metal we will be able to help you. Using the latest Trumpf 3030KW fiber laser technology we can cut work from 0.3mm to 12mm thick. Using a fibre laser enables us to offer you a comprehensive laser cutting service. We can laser cut ferrous and non-ferrous materials. As well as stainless steel this can include aluminium alloys, mild steel and galvanised steel. Using the fibre technology we can cut brass and copper alloys.

Employing either nitrogen, oxygen or compressed air as the cutting gases we can ensure the best edge quality to suit your needs. This also helps us to select the right solution to keep your finished part costs down.

Laser cutting stainless steel is only one service we offer our customers. For a fuller picture please take a look at our plant pages and galleries. If you have a design that needs sheet metal work please give us a call. Our engineering team will be happy to help you and talk through your ideas.

-

Spot welding a light fitting for the ceiling

11 September 2018Are you interested in finding a reliable company to produce your sheet metal work? Here at V and F Sheet Metal we offer a wide range of services using up to date manufacturing equipment.

If you have a product that needs spot welding in its final production then we are the company to come to. We have 4 spot welding machines with the largest capacity being 30KVA. This range of spot welding machines enables us to be flexible to meet your needs by working on spot welding several jobs at a same time or setting all four spot welding machines to fabricate the same sheet metal parts when larger orders are placed or very short lead times are required to meet a tight production deadline.

Take a look at our very latest blog post on spot welding ceiling light fittings:

http://www.vandf.co.uk/blog/spot-welding-zintec-ceiling-light-fittings/

Give us a call or drop us an email, we're always willing to discuss your project ideas.

-

Producing bespoke sheet metal brackets

28 August 2018An interesting project recently came our way particularly as it took us down a slightly different avenue to our normal production work. The customer was looking for a supplier who could produce bespoke metal furniture brackets, these would then be used in the assembly of a range of contemporary sleek looking stools, chairs and tables. For a more detailed description of the process involved in making these brackets, including photos of the brackets, final products and production videos showing the punching and bending processes, please click on the following link:

http://www.vandf.co.uk/blog/manufacturing-bespoke-metal-furniture-brackets-at-v-and-f-sheet-metal/

If after reading this you think we could help you then please contact our engineering team at V and F Sheet Metal on 01489 577786 or drop us an email at sales@vandf.co.uk. We are always keen to help improve our customer's designs to aid manufacturing and save them money.

We can't wait to hear from you!

-

Advantages and disadvantages of plastic coated materials

16 July 2018Plastic coated materials

I noticed this job going through the factory today so it has provided me with the opportunity to talk about the pros and cons of pre-coated materials. The customer called me and asked if we could manufacture a batch of 300 electric motor covers. This is not a difficult job for us here at V and F Sheet Metal so obviously the answer was yes! These covers were produced from mild steel with zinc coating on the underside. As you can see from the image the top face has a thick white plastic coating bonded to it and on top of this sits a low tac 4 thou (0.1016mm) peelable protective film. Whilst the cutting and and bending process takes place, the film actually stays in place and remains there whilst the components are being transported to the customer. It is removed at site by the customer.

Plastic coated flat blank

The flat blanks here were punched out using our Trumpf 3000R punching machine. This takes more time than using our Trumpf fibre laser but unfortunately in this case the plastic coated material (as seen here) is not suited to laser cutting. This would be the same for reflective pre-anodised reflector material or pre-painted metal.

Some of you may be interested in the material used for this job. In this case it was 0.9mm mild steel but with the coating on it measures 1.2mm. The coating is extremely durable and tough with a leatherette finish. It would be a good coating to use for something such as a radiator cover. Another advantage is that it is relatively cheap as it bypasses the need for another process such as powder coating. However, unlike powder coating it does leave exposed edges so is only suitable for interior settings.

Need a quote from us?

That's no problem, we're happy to help! After all that's what we're here for! Take a look at our website for more insights into past and recent sheet metal projects and the help we can give you with your designs. There’s also a useful section dedicated to our plant list and detailed help on tooling.

If you are looking to purchase metal work in Great Britain, then do it it’s easy! No complications with language problems or expensive shipping costs. Just pick up the phone and talk to us on 01489 577786. Alternatively send us your drawings to sales@vandf.co.uk and we will produce some estimates for you.

-

Reflector assembly using tabs and slots

26 June 2018If you are interested in having your aluminium reflectors made but are unsure who to contact, then your search is over! Here at V and F Sheet Metal in Fareham on the south coast of England we have many years of manufacturing experience and will guide you through the process from design to production in a reliable and professional fashion.

We will give you the correct advice to make sure your product is manufactured to the highest quality. Please contact us at our factory in Hampshire where our friendly and experienced staff are always happy to help you.

You may enjoy reading our latest blog post on producing aluminium reflectors. This will be of particular interest if you would like to know more about a method of assembly using tabs and slots.

http://www.vandf.co.uk/blog/we-are-in-a-reflector-mood-at-v-and-f-sheet-metal-today/

-

Let's take a look at laser cutting small components

3 April 2018Are you looking for someone in the UK to produce batches of small components for you? Then look no further as here at V and F Sheet Metal in Hampshire we have the capacity to do this for you.

Perhaps you're worried about the cost of tooling and whether this is going to significantly push up the overall price? Well the good news is if we use our versatile laser cutting machine, there is no need for dedicated tooling!

Take a look at our blog post to find out a whole lot more. If you think we can help you then please don't hesitate to give us a call on 01489 577786 or email us today at sales@vandf.co.uk.

http://www.vandf.co.uk/blog/laser-cut-small-components-in-hampshire-great-britain-2018/