AML Instruments Ltd

AML Instruments are a family run business offering instrumentation, UKAS ISO 17025 calibration, service, repair, spare parts and support for a wide range of instruments / test equipment used in a variety of industries and applications.

Filter products and services

- View all categories

- Autoclaves

- Balances

- Bore Micrometers

- Calipers

- Climatic Chambers

- Counting Scales

- Depth Gauges

- Dot Matrix Printers

- Electrical Calibration

- Environmental Chambers

- Floor Scales

- Force Analysis Systems

- Force Gauges

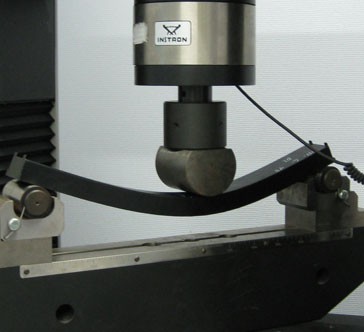

- Force Testing Systems

- Furnaces

- General Purpose Laboratory Ovens

- Heating Ovens

- Height Gauges

- Hot Plates

- Humidity Calibration

- Incubators

- Indicators

- Laboratory Freezers

- Laboratory Fridges

- Laboratory Thermometers

- Load Cells

- Material Testing Systems

- Micrometer Heads

- Micrometers

- Moisture Measurement Devices

- Peel Fixtures

- Pressure Calibration

- Steel Rules

- Temperature Calibration

- Thermal Printers

- Thermometers

- Thickness Gauges

- Viscometers

- Water Baths

-

Falling Dart Impact Tester Dx-8000 Series Oakland Instruments

Easy to use Falling Dart Impact Tester for the determination of impact strength/toughness of plastic films/sheet and laminated materials. ASTM D 1709/ISO 7765 Method A, 66 cm drop height and dart diameter of 38mm ASTM D 1709/ISO 7765 Method B 150 cm drop height and dart diameter of 51 mm. Method B Instruments can also be used for Method A as the drop height is adjustable and is supplied with a second set of darts, with greater mass and diameter. Our Falling Dart Impact Testers can be configured to comply with all major national and international standards or customisable for your own in house testing requirements. Improve Film and Sheet Quality, Reduce Waste & Increase Profit Margins. It can be used for the production and additives setting ans adjustments, research and development of new film and sheet products, inspection of incoming film and sheet products and in-process checks to ensure on-spec product for converting operations.Request a Quote Supplied by AML Instruments Ltd -

Novo-Gloss Lite 45° Glossmeter Repair

AML Instruments offer the repair of Novo-Gloss Lite 45° Glossmeter. For all Novo-Gloss Lite 45° Glossmeter repair enquiries please call 01522 789375 or visit our website for more information.Request a Quote Supplied by AML Instruments Ltd -

Rockwell Hardness Tester Zwick Roell Indentec

Indentec is the only British manufacture of Rockwell Hardness Testing Machines. Indentec Rockwell Hardness Testers are high quality and accuracy machines which are completely made in the West Midlands. Indentec is part of the Zwick Roell Group which is a large German company established over 150 years ago who specialises in materials testing equipment and instrumentation. The Rockwell Hardness Tester Key Feature include a nose mounted indenter, a operator interface options with data logging software available. It has X-bar or range statistical process control with upper and lower tolerance. It also has an automatic test cycle, programmable dwell times and true direct depth measurement calibration. You also have the option for motorised lead screws. There are standard ranges of support tooling's, fixture and indenters but bespoke fixtures can be designed to suit individual customer requirements.Request a Quote Supplied by AML Instruments Ltd