AML Instruments Ltd

AML Instruments are a family run business offering instrumentation, UKAS ISO 17025 calibration, service, repair, spare parts and support for a wide range of instruments / test equipment used in a variety of industries and applications.

Filter products and services

- View all categories

- Autoclaves

- Balances

- Bore Micrometers

- Calipers

- Climatic Chambers

- Counting Scales

- Depth Gauges

- Dot Matrix Printers

- Electrical Calibration

- Environmental Chambers

- Floor Scales

- Force Analysis Systems

- Force Gauges

- Force Testing Systems

- Furnaces

- General Purpose Laboratory Ovens

- Heating Ovens

- Height Gauges

- Hot Plates

- Humidity Calibration

- Incubators

- Indicators

- Laboratory Freezers

- Laboratory Fridges

- Laboratory Thermometers

- Load Cells

- Material Testing Systems

- Micrometer Heads

- Micrometers

- Moisture Measurement Devices

- Peel Fixtures

- Pressure Calibration

- Steel Rules

- Temperature Calibration

- Thermal Printers

- Thermometers

- Thickness Gauges

- Viscometers

- Water Baths

-

Carton Force Analyser - Cfa Hanatek

The Hanatek Carton Force Analyser measures the forces that limit the running speed of folding box board packaging. By measuring the stiffness of the substrate and crease bending resistance the user can optimise cartons for faster running and packaging speeds. The instrument allows individual creases to be analysed identifying problem areas in packaging design or manufacture. Industry research indicates that the packaging speeds of pre-glued skillets is governed by the energy required to open creases. The Hanatek CFA is the first instrument to isolate and accurately measure this key parameter. The instrument measures: Bending resistance, bending moment, bending stiffness, crease recover stiffness, crease folding force, crease opening force. The Hanatek CFA can measure crease folding force at 90°, crease folding force at any angle up to 145°, board stiffness at 15° and 7.5°, individual crease opening force and whole carton opening force. It features touch screen operation for quick and easy operation. There are variable sample lengths available, rotation speed and crease angle. The instrument allows you to connect to a network to allow results or printer sharing. There is an online graphical help to ensure consistent operation within test methods and the interactive help routines ensure little training is required to operate the device. The Hanatek CFA is pre loaded with ASTM/TAPPI/ISO methods with the ability to create bespoke tests and in complain with all major international standards.Request a Quote Supplied by AML Instruments Ltd -

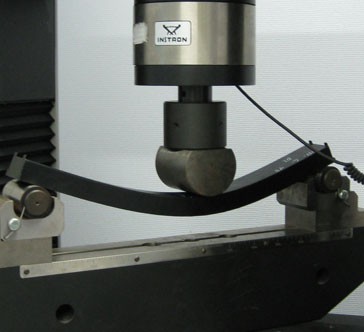

Crease And Board Stiffness Tester Cbt1

The CBT1 Crease & Board Stiffness Tester gives board manufacturers, printers and packing companies the ability to predict the 'runability' of a sample board or finished carton. The instrument measures crease folding force at 90°, board stiffness at 15° and requires no external software for operation. It automatically calculates the crease to board stiffness ratio for immediate indication as to whether the material will run correctly on a high speed packaging machine. After 15 seconds the test results is displayed on screen and a countdown timer for test completion is shown. After multiple samples are tested, the statistics (min, max, average) are updated on screen. There is an option test jaw for rounder comer packaging and option results printer to output test results to a label. There is a choice of sample cutters for the preparation of both carton crease and board stiffness samples.Request a Quote Supplied by AML Instruments Ltd -

Rea Scancheck 3 Barcode Verifier

The REA ScanCheck 3 is a universal high performance bar code verifier which meets to ISO standards. It creates reports which allow to prove that quality agreements are fulfilled. Automatic size determination provides straightforward use and user independent verification. The measuring system is based on a laser scanner system adapted to the requirements for verification. This technique leads to contactless measurements. The power supply is provided by standard AA rechargeable batteries. This allows fully portable operation. The REA ScanCheck 3 supports German and English. Other languages can be added by the aid of a translation tool. For fast and ergonomic operation the REA ScanCheck 3 is equipped with a large colour display and a powerful 32bit CPU. Reports can be stored locally or saved on a PC using a USB/Network device and REA TransWin32 software. Additionally the REA ScanCheck allows connection of a portable battery powered report printer. The REA ScanCheck 3 always includes a GS1-128 data content checker at no extra price.Request a Quote Supplied by AML Instruments Ltd -

Temperature/Environmental Chambers For Tensile Testers And Universal Testing Machines -90°C + 350°C

The TH2700 has a self-supported two-fold body frame made of stainless steel 2mm, it is melted, polished and brushed from the outside and the front door contains four glass-platens. It has a heating power of 2.3kW (220 volt) and a temperature range of -90°C- +350°C (please specify range required). Air circulation with a centric blower and there are heating coils between the inner glass platens to remove frosting of the glass., there is also an optional door light and internal light. The up and down hole as a Teflon guide tube outside and V2a inside. We can also insert shells to reduce to a smaller diameter for the Pull rods. There is an external regulator self turning 0.1°C Sika TLK96 (optional omron RS232 or Eurotherm RS485). The TH2700 has a 19" rack with 4m cable and plug and a frame to move chamber in and out of tensile tester. The Chamber has adjustable feet and can be carried by the bearings so it can be moved 611mm away. The heat up speed is 15°C/Minuitte (from 20-80°C without grip). The cooling requires liquid nitrogen, which is controlled by a magnetic valve at the rear of the chamber. Our Temperature/Environmental Chambers are all manufactured in Germany to the highest standards.Request a Quote Supplied by AML Instruments Ltd