BeaconMedaes

Company Overview

BeaconMedæs is a Global leader in medical gas pipeline (MGPS) turnkey solutions. With services including preventative maintenance contracts, equipment servicing, installation and commissioning, site surveys and design services to HTM02-01 standards.

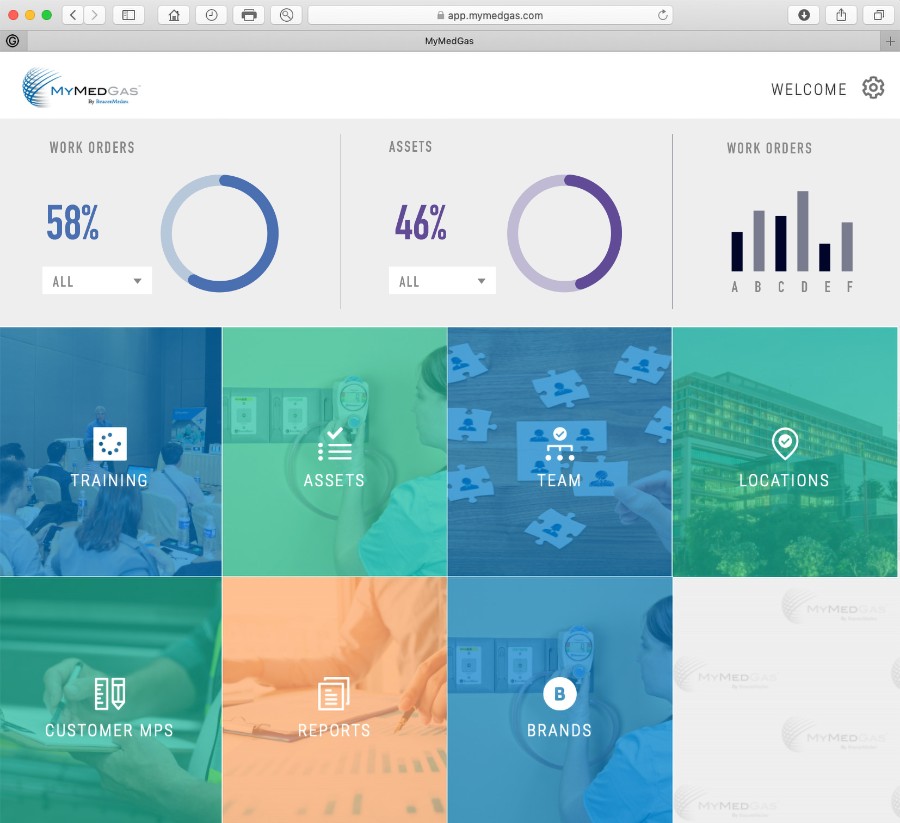

MyMedGas by BeaconMedaes is a new way to manage your medical gas pipeline system (MGPS). It provides one central digital location from which everything relating to the MGPS can be easily overseen and managed, with data accessed at any time and from and place.

Our installation team offer unrivalled experience and expertise with our products. With pre qualification through such quality bodies as Safecontractor, CHAS and Constructionline you can be sure we take Health and Safety and quality service seriously. BeaconMedæs has a proven track record of delivering projects on time, from major acute facilities to small extensions and refurbishments, so whatever the size of the job we can help you out. Following installation, we can provide verification, testing and commissioning, preventative maintenance contracts and emergency repair services.

Medical gas service and support is central to everything we offer our customers, and we maintain the UK’s largest service force dedicated exclusively to medical gas systems. We provide full mainland coverage and emergency 24 hour call-out so day or night, 24-7 we have your medical gas systems covered.

Our products are UK manufactured and CE marked to the medical devices directive including medical air plant, medical vacuum plant, AGSS, gas manifolds, GEM terminal units, medical gas alarms, valves as well as architectural products such as area zone service units, pendants and bedhead trunking to HTM02-01 standards.

Whatever services you require your medical gas system is safe in our hands.

Please contact us today for any works relating to your medical gas system and we will arrange for one of our regional sales engineers to visit site.

Installation Services - MGPS

Installation Teams

BeaconMedaes have been providing high quality Installation Services for many years. We employ the most experienced medical gas pipeline installers in the UK. Our installation service covers acute hospitals, veterinary surgeries, dental practices, as well as teaching and private hospitals.

BeaconMedaes have a wealth of knowledge when it comes to best practise, both here in the UK and within our export markets.

Project Management

BeaconMedaes is capable of providing expertise at all levels – from Medical gas Competent Person (CP) to Authorised Person (AP). Our knowledge of Medical Gas Pipeline Systems (MGPS) is derived from over 40 years of experience in the field.

Professional Design Services

Before a project begins our Sales Support team offers expert medical gas design services, to assist your design professionals with the specialised design work of the medical gas pipeline system.

Site Surveys

Our Installation work starts before the engineers come to the site. When we receive a request to quote Medical Gas Pipeline Systems (MGPS) work, we generally visit the site to ascertain any existing drawings are accurate as well as compliant to current standards (HTM02-01). The on site surveys are essential where new pipe work is required, and our engineers will take measurements to include existing and proposed usage so that the correct pipe sizes are used in the job.

Isometric drawings and plan drawings are used to extrapolate all possible components of the installation. In addition, we take into account any proposed future expansion, in order to save client costs going forward.

BIM Drawings

Our experienced sales support team will provide room layout drawings in 3D revit format, to ensure equipment can be located and installed easily. Ensuring post installation all serviceable items are easy to access.

Pipeline designs are also provided in 3D with a suite of drawings including full isometric, schematic diagrams, flow calculation drawings, as fitted and as installed drawings.

Service and Maintenance - MGPS

Field Service

BeaconMedæs has the largest field Service and Maintenance force in the industry and has the ability to reach any mainland facility with the best response times. Our service specialists possess a vast knowledge of the industry and are able to work on all other manufacturer’s equipment. BeaconMedæs service specialists have the knowledge, skills and parts to complete the work on the spot and all technicians are certified Competant Persons (MGPS). You can rest assured that planned and corrective maintenance can be handled rapidly to maximise equipment uptime. In addition, our factory maintains a large inventory of parts available for quick despatch if required.

Planned Preventative Maintenance

Planned Preventative Maintenance (PPM) is inspection work that is performed on a piece of equipment on a scheduled basis. The schedule is based on best practices and manufacturers’ recommendations designed to keep your equipment operating smoothly.

Corrective Maintenance

Corrective Maintenance is repair work that is performed on a piece of equipment to restore it to proper operating condition. This is typically unscheduled work, requested by the customer or person performing planned maintenance. BeaconMedæs not only offers competitive labour rates and OEM parts pricing, but stands behind both for 90 days.

MyMedGas

MyMedGas allows you to manage your entire Medical Gas Pipeline Systems (MGPS). We connect all the details on compliance, assets tracing, equipment history, competence development and 24/7 support. Our easy to use digital platform includes features such as inventory asset management, monitoring of equipment, maintenance history, reports, compliance status and much more. Together with our nationwide service organisation you get full control of your MGPS, ultimately supporting your patients.

MedGasScan - Reduce risks and costs by identifying leaks on your Medical Gas Pipeline System

BeaconMedaes has been a trusted partner to healthcare facilities around the world. We understand the increased demand on your MGPS like no other. Our MedGasScan audit enables you to identify oxygen and other medical gas leaks on your pipeline and equipment, helping you to calculate the total losses on each gas pipeline and determine the amount of gas lost per annum. This can be converted back to a cost-saving for your facility, as well as help you eliminate the potential fire risk associated with oxygen leaks and reduce the large negative carbon impact of gases such as nitrous oxide and nitrous oxide/oxygen mixture (50% v/v).

How does it work?

- The camera detects ultrasonic signals produced by loss of gases such as oxygen, nitrous oxide, nitrous oxide/oxygen mixture, or medical air, which are not audible to the human ear.

- It forms an accurate acoustic image which is transposed in real-time on top of a digital camera picture, which allows the user to accurately see from which directions sound is arriving.

- Once the gas system has been tested and tagged, a comprehensive report is produced highlighting any leaks on the system.

- In the report, a visual record of the leak is produced - the louder the leak, the darker the image, with colours ranging from yellow to red.

- The report is uploaded onto our cloud-based MGPS asset, compliance and risk management system, MyMedGas.

MyMedGas by BeaconMedaes allows you to manage your Medical Gas Pipeline System.

MyMedGas

MyMedGas by BeaconMedaes allows you to manage your Medical Gas Pipeline System. Starting from compliance, assets tracing, equipment history and finishing with competence development and 24/7 support. Our easy to use digital platform includes different key modules, these are: inventory asset management, monitoring of equipment, maintenance history, report and compliance status. BeaconMedaes, the national wide service organization, combined with MyMedGas is the solution to get your Medical Gas Pipeline System (MGPS) under control and fundamental to ensure support for your patients.

For more detailed information, visit our dedicated MyMedGas website.

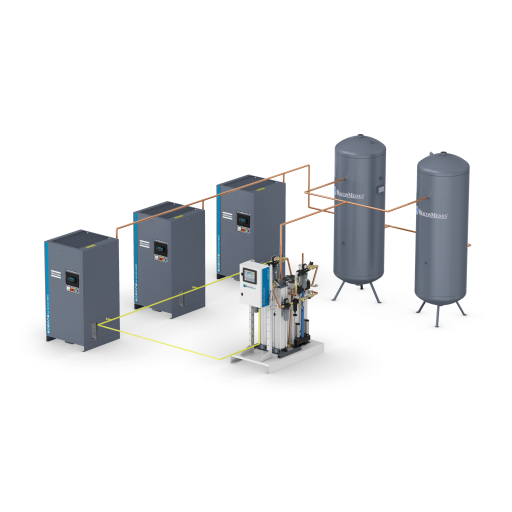

Medical and Surgical Air Systems

mAIR, sAIR and cAIR Air Systems

At BeaconMedaes, we strive to offer products that meet your specific hospital needs. We have a broad range of air plants for different applications. Our mAIR systems offer medical air at 4 bar for breathing applications. sAIR systems are specifically configured for surgical applications, delivering air at 10 or 7 bar. We also provide cAIR systems for combined breathing & surgical air at 10 or 7 bar.

A proper managed compressed air network will save energy, reduce maintenance, decrease downtime, increase reliability and improve product quality. The ES medical central controller is the most efficient way to monitor and control multiple compressors and air purifiers simultaneously.

In combination with our dMED medical air purification module, oil-injected screw air systems deliver medical air in compliance to the European Pharmacopoeia. The dMED comes pre-piped and wired in a fully duplexed package. It has a six-step purification process with a Hopcalite option that provides European Pharmacopeia compliant medical air.

Oil-free Medical Air Systems

Remove the risk of oil carry-over into your hospital pipelines by using our oil-free air systems. With certified Class 0 medical compressors, oil-free air plants are the obvious choice when it comes down to ultimate patient safety. A wealth of compressor technologies are available that offer you 100% oil-free medical air.

SF MED oil-free tooth compressors

Our SF MED oil-free scroll compressors are specifically designed to be part of a medical air system. With flow rates that closely match most hospital demands, you will be able to find a scroll air system that fits your needs. Our multi-core SF MED’s offer extended redundancy, as a shutdown of one element will not cause the full unit to stop. Combined with a very low noise level, this compressor type is the ideal oil-free technology for medical applications.

ZT MED oil-free tooth compressors

Our ZT MED rotary tooth compressors offer high energy efficiency at large flow rates while meeting your needs for oil-free air. Specifically modified to be part of a medical air system, they provide the highest levels of reliability. For those who look for even lower energy consumption, the ZT MED tooth compressors are also available with Variable Speed Drive.

mVAC - Medical Vacuum Systems

BeaconMedæs and Atlas Copco have combined their expertise and knowledge to create the Medical Vacuum Plant. Main improvements are increased performance, usability and an advanced control system which provides remote live monitoring. Additionally, user friendliness is enhanced with the easy to operate central plant controller with a 5.7” colour display. By reducing the footprint and providing easy access to serviceable parts the new mVAC plant provides better usability and easy maintenance.

For increased flexibility, and areas where access can be more difficult we also have a floor mounted system.

AGS - Anesthetic Gas Scavenging Systems

The Anesthetic Gas Scavenging System removes anesthetic gas mixtures in areas fitted with nitrous oxide terminal units like operating rooms. By virtue of its design, the active disposal system can produce high capture levels simply by connecting the terminal unit to the anesthetic breathing circuit via a receiver unit. This removal at the source eliminates the possible long term health hazards for the exposed medical staff.

Lifeline Manifold Control Systems (MCS)

The Lifeline® MCS Manifold is a compact and fully automatic manifold control system for medical gases. Regarded as a leading manifold control panel in its class, the Lifeline® MCS Manifold combines ease of use, installation and maintenance with a very high flow capacity. We use two stage regulators in our manifolds as standard. This results in a leading high flow capacity of 1,750 lpm at 4 bar stable pressure over the entire flow range. We always use halogen free high pressure regulators which reduce the risks of self-ignition and emission of toxic gases.

The manifold has a graphical display with a precise pressure indication which give you visibility on your medical gas consumption. Additional visuals of remaining cylinders gas volume and average flow consumption provide full control over your medical gas installation.

The digital control panel and two stage regulators allow for low changeover pressure that can save you thousands liters of valued gas annually. This saves you money.

Emergency Reserve Manifolds (ERM)

The BeaconMedæs Emergency Reserve Manifold (ERM) is designed for compliance with HTM 02-01 guidelines. The ERM is used to support the main manifold and is connected downstream of the manifold control panel. The Lifeline ERM is capable of high flows capable of supporting large medical systems.

For lower flow rate gases or applications, we have our Lifeline ECO ERM.

ERM's come as 2x1 standard, with an optional 1x1 cylinder extension kit. ERM's can then be extended to any size desired, although note HTM02-01 states a max 2x2 should be used.

Medical Gas Outlets / Terminal Units

The BeaconMedæs provide an extensive range of high quality Medical Gas Outlets / Terminal Units. Gem terminal unit’s provide exceptional reliability is a testament to it unique pedigree. In terms of quality, reliability, and value, the Gem terminal unit is in a league of its own. Fully complying with BS EN ISO 91701:2008, the BeaconMedæs Gem has a proven service record, and is available in a wide range of mounting options, connection types and orientations to suit installations in walls, bedhead trunking, headwalls and pendant systems. New for 2015, the Gem "Shield" retains all the strengths of the Gem 10 - including the same check valve and mounting dimensions, making the units interchangeable for easy 2nd fix upgrades. Additionally, the Gem "Shield" comes with Biomaster antimicrobial additive in all user accessible parts to actively reduce the growth of bacteria thus limiting the chance of cross infection.

From 2022 BeaconMedaes increased it's heritage by incorporating the Penlon/PMGS East SP and Zeus SP range of terminal units.

Monitoring Equipment

Our widely used and trusted MediPoint Medical Gas Alarm just went Digital

Our new Digital Medipoint retrofit alarms are a direct replacement for previous generation Medipoint alarms and make for a smooth upgrading. Easily view gas service type, colour, pressure and vacuum units, and monitor your gas service status. For more information, please contact us.

Digital Medipoint 26 Design

BeaconMedæs Digital Medipoint 26 Medical Gas Alarms offers a color touchscreen display designed to provide real-time monitoring of up to 6 gas services in the normal, high and low pressure conditions. With the password protected on-screen menu set-up is easy. Line contact monitoring circuits constantly monitor the integrity of the pressure sensors and interconnecting wiring.

Digital Medipoint 125

BeaconMedæs Digital Medipoint 125 Medical Gas Alarms offer a color touchscreen display designed to monitor up to 5 gas services or twenty point alarm conditions. With the password protected on-screen menu set-up is easy. Each alarm panel may be used as an input or repeater panel, as part of the total central alarm system. Line contact monitoring circuits constantly monitor the integrity of the pressure sensors and interconnecting wiring. In the event of any fault, the line contact monitoring circuits initiate the specific gas service failure indication, a "System Alarm" indication and the audible warning.

Medizone & Wallzone - Area Service Module

Immediate access to your medical gas pipeline system

The Wallzone™ Area Service Module offers a cost-effective design that incorporates the BeaconMedaes ZSU2 Zone Service Unit and Medipoint 26 Digital Medical Gas Alarm, providing quick and safe access to the pipeline system. It includes a powder coated mild steel 2nd fix design to create a corrosion-proof and easy to clean enclosure. Since all piping, wiring and pressure testing is completed prior to delivery, factory-controlled quality is assured. The Wallzone can be surface or semi flush mounted to answer your hospital’s specific needs.

The Medizone™ Area Service Module is an effective method of installing a number of services and equipment in a factory pre-built and tested unit allowing for quick installation. The Medizone’s compact and sleek appearance is suitable for any modern hospital environment. A wide range of laminate finishes are available. Both surface and flush mounting versions are available, with each unit being custom built for the particular application. Each Medizone™ is usually dedicated to a single area or ward, with pressure switches, alarm and up to 6 zone service units for an area being installed at the entrance or preceding corridor.

ZSU2 - Zone Service Unit (AVSU - Area Valve Service Unit)

The most reliable Zone Service Unit

The ZSU2 Zone Service Unit used in both Medizone and Wallzone Area Valve Service Unit modules provides a zone isolation facility, for use either in an emergency or for maintenance purposes. It also provides a physical breakpoint to allow work to be safely carried out on the pipeline. NIST connections are positioned both up and down stream of the valve. These enable the facility to connect cylinder trolleys in the event of emergency, maintaining gas supply to the patient.

Bedhead Units - The perfect modular bedhead solution for your hospital

Improve the look of your patient environment

The BeaconMedaes Bedhead Units offer LED lighting, electrical sockets, nurse call components, monitoring, telephone jacks, and medical gas outlets, all conveniently housed in the aesthetically pleasing powder coated aluminum profile.

Thanks to the modular structure, numerous equipment variants are possible, with or without gas outlets. This makes the bedhead unit the ideal choice for hospitals, clinics, nursing homes, rehabilitation centres, and many other healthcare facilities. The systems can be equipped with nurse call components, sockets and gas outlets from all well-known manufacturers. This guarantees 100% compatibility with the in-house system.