Weartech International Ltd

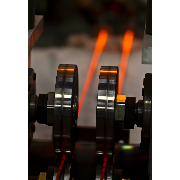

We are one of the world's foremost producers of cobalt- and nickel-based hardfacing and wear-resistant alloys.

We can offer a wide range of hardfacing products and components to many different industries including:

- Oil and gas industry

- Petrochemical industry

- Timber industry

- Power generation industry

- Metal forming industry

- Automotive industry

- Marine valves industry

- Steel mill and galvanising industry