What is a Vacuum Switch?

8 December 2022Here at Applications Engineering, we supply single and double throw vacuum switches to our customers. But what is a vacuum switch? Let’s take a deeper look at what vacuum switches do and where you can expect to find them.

What is a Vacuum Switch?

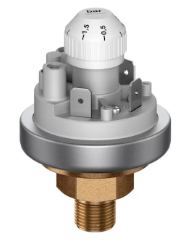

In a nutshell, a vacuum switch provides a switching contact function whenever a predetermined vacuum gas pressure level is reached. This may be to relieve pressure in a system or it may be engaged to increase the pressure. They are a common feature of the hydraulic, pneumatic and processing industries and essential for operations.

For fluidic and liquid processing systems, a vacuum switch is there to trigger a circuit in the event of a vacuum being compromised. Whenever these switches sense a change in the vacuum, they open or close an electrical circuit. Not only is this essential for functionality, it’s also important from a safety aspect to prevent pressure from building up too much.

These switches can be adapted to match specific thresholds, ensuring that whatever purpose you have for them, they will be fit for the job. Our vacuum switches come in two basic forms: single throw and double throw.

Poles and Throws: What’s the Difference?

Our single pole vacuum switches come in two variations: single or double throw. It’s important to understand the roles of each switch when buying a vacuum switch for your needs.

Poles

A single pole switch has just one input and one output, meaning it has just two statuses – either on or off. When wiring these switches, it’s possible to configure them either normally open or normally closed.

Double pole vacuum switches have two connections to two separate circuits. Essentially, they are two switches in one and can be either staggered or connected simultaneously.

Regular single pole switches can be found in everyday items like home appliances, light switches and alarms. Similarly, common double pole switches are used for things like medical applications or light and fan combinations.

Throws

While there can be double and single poles in vacuum switches, there can also be either single or double throws. A throw refers to how many positions a switch can activate.

Single throw switches close a circuit in one position while a double throw switch has the capability for closing a circuit in two positions. Double throw switches also have a neutral position where neither circuit is activated.

Where Vacuum Switches can be Found

One of the most common industries where you can find a vacuum pressure switch is hydraulics. Vacuums are important for hydraulics, so regulating the pressure build-up is critical for keeping hydraulic equipment working.

Hydraulics are typically used for moving parts of mechanical systems that lift, push or pull heavy objects. They use a pump that draws in liquid which creates a vacuum at the inlet. When the pressure is increased, fluid is forced into the inlet, moving the hydraulic equipment. Regulating the pressure and vacuum is essential to ensuring sudden pressure fluctuations don’t occur, which could collapse the entire hydraulic arm or lever.

You can expect to find hydraulics in places like car manufacturing plants, construction machines and amusement park rides. They are also useful for more simple things like office chairs. No matter where hydraulics are used, given the loads they are typically responsible for handling, they need to operate at the right pressure.

Other Applications Engineering Products

At Applications Engineering, our customers can rely on us for exceptional quality products. We are also happy to advise anyone who should need it about any of our products – our team members hold expert knowledge in all areas.

Vacuum switches are just some of the products we supply to our customers throughout the UK. We are also a leading supplier of pressure switches and pressure transducers