Applications Engineering Ltd

Since opening for business in Uckfield, East Sussex in 1983, Applications Engineering Ltd has become synonymous with the supply of control and instrumentation products.

Our impressive array of items offered include; pressure switches, differential pressure switches, pressure transducers, pressure gauges, level switches, level sight indicators, flow switches, flow sensors, float switches, solenoid valves, temperature switches, temperature sensors and vacuum switches.

Product quality and service is of utmost important to us and we are proud to declare that our Management System has been approved to ISO 9001 status since March 2003 (currently certified to 9001:2015) and is approved and annually audited by ISOQAR. Without this, we wouldn’t have been able to supply into some of the worlds’ most prestigious manufacturers supplying the exacting needs of the military industry.

NEXT DAY DELIVERY is on offer for most products as we store a large volume of stock at our facility in Uckfield, East Sussex. Customers can also come and collect products from us, if need be.

Filter products and services

-

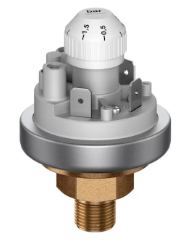

Pressure Switch Single Pole Double Throw

Single pole double throw pressure switches off the ability to choose either a normally open or normally closed contact within one switch, they also have the added advantage of being able to switch from one circuit to another. Single pole double throw switches are generally able to handle a greater current than single pole single throw pressure switches and are therefore more suited to more demanding applications. Applications Engineering are able to offer a comprehensive range of single pole double throw pressure switches at unbeatable prices so get in touch and let us help with your requirements.Request a Quote Supplied by Applications Engineering Ltd -

Pressure Switch Single Pole Single Throw

Single pole single throw pressure switches are a simple low cost way to monitor pressure in a system, they are available with either normally open or normally closed contacts. Applications Engineering have a range of single pole single throw switches available with many different options including thread types, electrical connections and body materials with adjustment ranges from 0.1 to 1 bar to 30-300 bar, adjustment is easily made via the screw in the contact housing.Request a Quote Supplied by Applications Engineering Ltd -

Pressure Transducer - 1200/1600 OEM Series

The 1200 series pressure sensor features stability and toughness via its CVD and ASIC design coupled with a thicker diaphragm. The thicker diaphragm enables these pressure transducer sensors to survive most pressure spikes caused by pump ripple, solenoid valves, etc. The 1600 series extends the packaging options by providing an all welded stainless steel back end for demanding industrial applications. A modular design allows special ordering of fittings, electrical cables, etc. for OEM applications. The ASIC and CVD technology enables Gems to offer almost any output over any pressure range.Request a Quote Supplied by Applications Engineering Ltd -

Pressure Transducer - 2200/2600 Series

The 2200 series pressure transducer features stability and accuracy in a variety of enclosure options. The 2600 extends the packaging options via an all welded stainless steel back end for demanding submersible and industrial applications. The 2200 and the 2600 pressure transducers feature proven CVD sensing technology, an ASIC (amplified units), and modular packaging to provide a sensor line that can easily accommodate specials while not sacrificing high performance.Request a Quote Supplied by Applications Engineering Ltd -

Pressure Transducer - 265 Series

The 265 is a very low pressure transducer for ranges as low as 6.35 mm (0.25?) W.C. and feature ±1% full-scale static accuracy. Primarily used in Building Energy Management these transducers are capable of measuring pressures and flows with the accuracy necessary for proper building pressurization and air flow control. 265 series transducers utilise an all-stainless steel micro-tig welded sensor that allows up to .69 bar (10 psi) overpressure (in either direction) with no damage to the unit. All sensor components have thermally matched coefficients, resulting in improved temperature performance and excellent long-term stability.Request a Quote Supplied by Applications Engineering Ltd -

Pressure Transducer - 276 Series

The 276 series pressure transducer features an extremely accurate and stable ceramic sensor to deliver a great value in environmental pressure measurement. Gems' glass-fused ceramic capacitive sensing capsule offers inherent thermal stability and low hysteresis in a proven, simple design. A custom ASIC used in the 276 series achieves long-term stability and high accuracy, and its low power requirements (as low as 5 Vdc) allow the sensor to operate in remote battery or solar powered applications. An integrated mounting bracket and 1/8? tube pressure connection ease installation.Request a Quote Supplied by Applications Engineering Ltd -

Pressure Transducer - 3100 OEM Series with Temperature Output Option

For OEMs that need consistent high levels of performance, reliability and stability the 3100 series sputtered thin film pressure transducer unit offers an unbeatable price/performance ratio in a small package size. It features all-stainless steel wetted parts, a broad selection of electrical and pressure connections, and a wide choice of electrical outputs to allow stock configurations suitable for most applications without modification. At the heart of this series is a sputter element that also provides exceptional temperature specifications. The manufacturing process for the 3100 series includes the latest automated equipment, producing the most consistent and best price to performance sensor on the market today.Request a Quote Supplied by Applications Engineering Ltd -

Pressure Transducer - 3200 OEM Series with Temperature Output Option

For OEMs that need consistent high levels of performance, reliability and stability the 3200 series sputtered thin film pressure transducer unit offers an unbeatable price/performance ratio in a small package size. It features all-stainless steel wetted parts, a broad selection of electrical and pressure connections, and a wide choice of electrical outputs to allow stock configurations suitable for most applications without modification. At the heart of this series is a sputter element that also provides exceptional temperature specifications. The manufacturing process for the 3100 series includes the latest automated equipment, producing the most consistent and best price to performance sensor on the market today.Request a Quote Supplied by Applications Engineering Ltd -

Pressure Transducer - 3500 OEM Series

For OEMs that need consistent high levels of performance, reliability and stability for low pressure measurement, 3500 Series pressure transducers are answer. They are compact and feature all-316 stainless steel wetted parts at an unbeatable price performance ratio. A wide choice of electrical outputs as well as both electrical and pressure connections means the unit is suitable for most applications without modification. Their small size makes of 3500 Series transducers ideal for installation where space is at a premium.Request a Quote Supplied by Applications Engineering Ltd -

Pressure Transducer - 4000/4010 Series High Performance

The 4000 series pressure transducer provides exceptional levels of stability and other performance specifications in a wide variety of enclosures from submersible to differential styles. By using a sputtered sensing element, which achieves a molecular fusion of a strain gauge material, an insulating material, and the 17-4 PH ss sensing element, the 4000 series transmitter provides the most stable sensor construction possible. These sputtered sensors are packaged for harsh applications requiring long term submersible service where precise laboratory type measurements are required.Request a Quote Supplied by Applications Engineering Ltd