Aquajet Machining Systems Ltd

As the UK's official OMAX distributor, Aquajet offer a complete range of OMAXCNC precision waterjet machines along with genuine OMAX accessories and consumables. Aquajet is part of a global network and can rely on 3 decades of knowledge and experience of high pressure cutting systems.

Utilising the latest technology from OMAX® Corporation, Aquajet are able to offer sub-contract machining to some of the tightest tolerances in the industry and have a highly skilled team of factory certified technicians which ensures we are ideally placed to assist you either in a sub-contract service or as a machine customer.

We work with many blue chip companies throughout the UK & Northern Europe. We specialise in short batch runs and tight tolerance machining. Our manufacturing facility is equipped with state of the art OMAX machining centres. Aquajet complies to Quality standard BS EN9001.

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world and its versatility has also allowed us to support the rapid growth of the stone and tile industry.

Aquajet offers a full catalogue of services including:

- Highly specialised subcontract job shop

- Machine sales (free lifetime software upgrades and support)

- Spare parts

- Service & Support

UK distributor of Rhino Board – latest innovative sacrificial cutting substrate

Aquajet offers knowledge and value that is second to none.

Filter products and services

-

OMAX Waterjet A-Jet 5 Axis Head

The OMAX A-Jet is a multi-axis accessory, that has the ability to compensate for tapering, and it is completely software-controlled. The accessory also compensates for severe cuts that go up to 60 degrees from the vertical. The operator determines the angles at which bevels and countersunk holes are made. It also has more axes of motion, allowing the operator to shape and fabricate the edges of metals in preparation for welding.

The OMAX A-Jet is a dynamic accessory which gives high positioning levels for accuracy, so you get parts that need no secondary cutting. Call us now and we shall tell you more about the amazing OMAX A-Jet.Request a Quote Supplied by Aquajet Machining Systems Ltd -

OMAX Water Jet Bulk Abrasive Delivery System

The OMAX Bulk Abrasive Delivery System is a heavy duty, bulk abrasive delivery system. It has been manufactured to the standards set out by ASME and has a CE mark. The system works with pressure of up to 125psi, and can be set at distances of up to 20 feet from the OMAX JetMachining Centre. Compressed air facilitates the movement of garnet from the Bulk Abrasive hopper to the 25-pound hopper on the machine.

The OMAX Bulk Abrasive Delivery System can hold up to 600 pounds of abrasive and is mounted on wheels for easy movement. Call us and learn how you can benefit from using the OMAX Bulk Abrasive Delivery System.Request a Quote Supplied by Aquajet Machining Systems Ltd -

OMAX Waterjet Collision Sensing Terrain Follower

With the OMAX Collision Sensing Terrain Follower, you will be able to accurately cut parts from irregularly shaped or warped materials when working with the JetMachining Centre. This is attached to the Z-axis, and it senses any changes in the shape of the material and makes the necessary changes in cutting standoff height. If there is an obstruction in the path of the nozzle, the collision detector stops the motion of the jet.

The OMAX Collision Sensing Terrain Follower works automatically and there is no need for any programming. Call us and find out how the OMAX Collision Sensing Terrain Follower can help you work with warped materials.Request a Quote Supplied by Aquajet Machining Systems Ltd -

OMAX Waterjet Drill Head

The OMAX Drill Head is specifically designed to piece composites and laminates, using the OMAX pneumatic drill. It allows you to repeatedly pierce laminates and composites before they are subjected to water jet cutting. You can use it to cut small holes in thick materials. There is no separate programming required thanks to the versatile and feature-filled Intelli-MAX software.

The OMAX Drill Head is mounted on the Y-axis carriage, but can easily be adjusted to the Z-direction when the operator wants to move it away when it is not being used. Call us and we will give you a demonstration of the OMAX Drill Head.Request a Quote Supplied by Aquajet Machining Systems Ltd -

OMAX Waterjet EnduroMAX Direct Drive Pump

The OMAX EnduroMAX Pump is a versatile pump created for OMAX JetMachining Centres. It lasts twice as long as other pumps and processes parts faster. It has low operating costs and low maintenance, making it a cost-effective pump. You can get the pumps in these models - 3060, 4060 and 5060, each giving your 30, 40 and 50 hp respectively.

The OMAX EnduroMAX Pump can run for several hours at 60,000 psi with ease. It has independent cylinders to ease the maintenance process. This is truly an effective water jet cutting pump. Call us now for more information on the OMAX EnduroMAX Pump.Request a Quote Supplied by Aquajet Machining Systems Ltd -

OMAX Water Jet Laminar Filter

The OMAX Laminar Filter is actually a settling tank where water coming from the Catcher Tank is allowed to settle and then recycled through the Closed Loop System (CLS) or discarded in an environmentally friendly way. The water is filtered through gravitational means; it has angled plates which ensure that the water flows slowly in a moving laminar way. The small particles fall through a short distance and get stuck when they hit the plates, thereby filtering the water. The clean water then goes to the CLS, or is disposed. Call us for more information on the OMAX Laminar Filter.Request a Quote Supplied by Aquajet Machining Systems Ltd -

OMAX Waterjet Laser Feature Finder

When you are using abrasive water jet cutting machines to cut valuable materials, it is prudent that you do a dry run before you do the actual cutting. The Laser Feature Finder is a laser that you attach to the nozzle in order to perform this dry run. It will also help you locate certain features of the material when it is placed at an angle.

The Laser Feature Finder works on all OMAX JetMachining Centres and is very easy to use. It operates on 3 A76 batteries and the polarised lens adjusts the size of the laser dot. Contact us for more information on how the Laser Feature Finder works.Request a Quote Supplied by Aquajet Machining Systems Ltd -

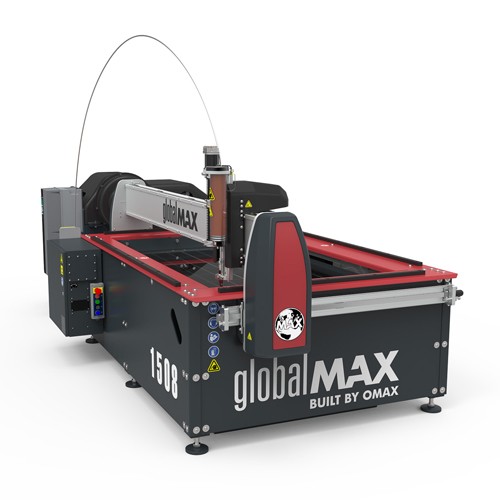

OMAX WaterJet Machining Centres

OMAX Jet Machining Centres offer the OMAX Bridge System Series, which allow you to apply abrasive water jet technology to produce amazing parts. You get the capacity to have cutting envelopes ranging from 0.74 meters all the way up to 10 meters; this is quite amazing, because you can produce large parts with ease.

At OMAX Jet Machining Centres, you get a guarantee for life-long access to any upgrades in software for your machine. This is a guarantee that you cannot afford to pass up. Call us now and see how you can benefit from buying your machines from OMAX Jet Machining Centres.Request a Quote Supplied by Aquajet Machining Systems Ltd -

OMAX WaterJet Machining Rotary Axis

With the OMAX Jet Machining Rotary Axis, you can now create complex 3D productions when using the Water Jet machine. This is a water-resistant submersible head that works in bar stock, pipe and tube productions. The Intelli-MAX software plays a great role here as it guides the head to cut complex shapes and angles. It is used together with the A-Jet articulated cutting head.

The precision indexed rotations allow for accurate cutting of geometric and multi-faceted shapes. This Rotary Axis expands the cutting capacity of OMAX JetMachining Centres. Call us on out hotline and get more information on how to use the OMAX Jet Machining Rotary Axis.Request a Quote Supplied by Aquajet Machining Systems Ltd -

OMAX Waterjet Motorised Z-Axis

The Motorised Z-Axis allows for movement in the Z-Axis for distances of up to 8 ¾". The controller has a pre-programmable automatic standoff which ensures that the nozzle is at the proper height from the work piece at all times. However, there are manual controls that allow you to have more control in some instances. There is a "Move all up" command which makes the nozzle move away fast after a piece of work has been completed.

Call us for more information on how the Motorised Z-Axis works.Request a Quote Supplied by Aquajet Machining Systems Ltd