Brooks Assist in Restoration of P2 Mikado Locomotive

14 December 2018Brooks Forgings are pleased to announce their involvement in a very special locomotive restoration project.

Our client is directly involved a modern build of the new P2 Mikado 2007 Prince of Wales, in its day one of the most powerful express passenger locomotives to operate in the UK.

We were approached to look at forging the foundation ring corner blocks, an integral part of the final boiler assembly. This was primarily to solve a problem that had developed with a flame cut version of the component produced from raw plain material, a design used on a similar boiler fitted to the A1 Class 60163 Tornado. Subject to constant temperature changes and varying loads, fatigue cracks started to appear. It was clear at this point that other methods of production needed to be explored and our client decided to source a stronger forged alternative.

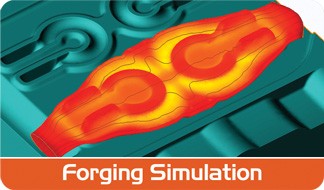

With a focus on the material grain flow, it was decided to start off by hot bending the plain material to the rough desired shape. This means that the grain flow follows the contours of the bend.

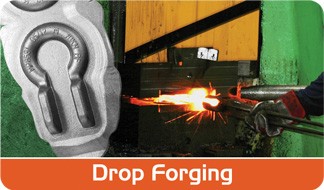

The bent material was then drop forged to achieve the final ‘blank’ form, further compressing the grain flow to provide the strength required. The forged blanks were then fully machined to the final specification.

The newly forged and machined foundation corner blocks were supplied on time and are now fully installed and in use on Tornado.