Brooks Win Manufacturing Achievement Award

14 December 2018Brooks Forgings Ltd, winners of the Manufacturing Achievement award in the 2013 Made in Midlands Business Awards.

Expanding through diversification, Brooks Forgings Limited has made several steps to reinforce the company’s presence in UK manufacturing.

The relocation of our manufacturing base to a new dedicated 45,000 sq ft site, located in Lye Stourbridge, has given the company room to expand further. The redundant manufacturing space was fully refurbished and now houses a new warehouse facility capable of holding an additional 1250 pallets of stock.

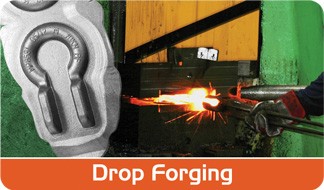

Our range of on-site manufacturing processes is one of the most extensive in the UK forging industry, now covering forging, machining and fabrication. This capacity ensures full traceability and quality of components, but also reduces the reliance on sub-contractors. Lead times are improved by having a rotational method of production. Components can move onto the next process, machining for example, while the batch quantity is still being forged.

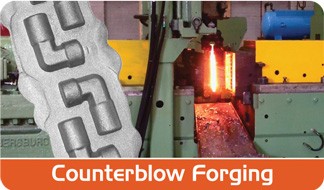

The Installation of a Model C Chambersburg Automated Horizontal Counterblow System, possibly the only operational machine in Europe, enables us to achieve higher volume production whilst using less energy through the use of programmable energy levels and blow patterns.

Over the last year we have also made key investment in strengthening our machining capacity. The purchase and installation of several additional CNC Lathes and Vertical Machining Centres increases our current machining capacity to 14 machines.

In July 2013 the company was audited for and subsequently awarded certifications in ISO 14001 for Environmental Management Systems and OHSAS 18001 for Health and Safety Management Systems. The company is also seeking CE approval by the end of Q4 2013.

Image: Left to Right. Clive Brooks - Chairman, Richard Noble OBE, Steve Brooks - Managing Director and Adrian Brooks - Financial Director.