Celebrating 50 Years in Business

14 December 2018Traditional metal-bashing skills and the latest computer aided technology have combined to make Black Country-based Brooks Forgings a nationally known name over it’s half century.

Still run by its founding family, it has expanded to operate from four sites across the region with divisions working on industrial and artistic ironwork products, eyebolts, U-bolts, shackles, galvanised fasteners, gates and bollards, as well as machining and global sourcing.

While still producing standard lines from stock, it is Cradley Heath based Brooks’ development of a range of specialist bespoke products that have made it a well known name.

Chairman Clive Brooks, who founded the business with the help of his father in 1960, said:

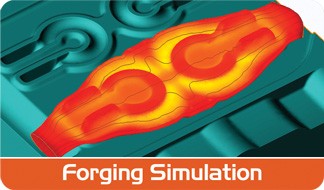

“Our clients talk to us because they know we recommend the best method of production for their job, project manage their work through the initial concept to design and then production to final delivery."

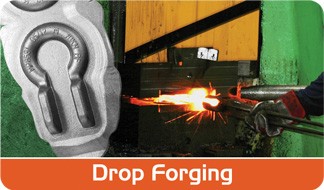

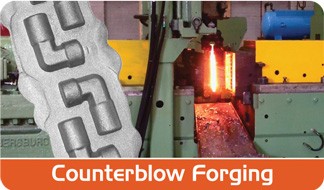

He added, “Our strength is our ability to produce virtually anything, often items our clients find difficult to source elsewhere. We have been known to purchase specialist equipment or to adapt existing machinery to ensure we are able to provide a quality product at a competitive price and in the shortest possible time. We have been able to remain true to our roots by retaining the traditional skills of the craftsman whilst embracing modern manufacturing technologies such as computer aided design, automated forging lines and robot welding machines."

The company has continued to expand through the recession, with it’s acquisition of a 45000 sq ft facility in Lye last year. Despite the recession, Brooks has also been investing heavily in new machinery, including a sawing line, two robot welding cells, three multiforges, and two further machining centres.

The firm has also installed a new destructive testing machine so that testing can take place alongside the manufacturing process. This prevents loss of manufacturing time as well as cutting the cost of sending items to external laboratories for testing. It also means clients can see parts tested on site.