Collaboration between Brooks and W.H.Tildesley on prestigious forging project

14 December 2018Brooks Forgings were given the opportunity to manufacture and export a requirement for 14 highly specialised lifting bail bars that are used to lift crucibles of molten aluminium at a treatment plant located in Bahrain.

This was the first collaboration project between Brooks Forgings and W.H.Tildesley since them joining the Brooks Engineering Group in April 2017.

We believe that we are one of a very limited number of manufacturers worldwide who could undertake and complete this project successfully.

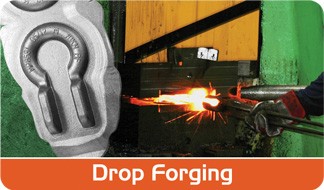

The bail bar had to be hot forged to achieve the directional grain flow required for strength and resilience. It was obligatory to provide full traceability and testing at all stages of production. This was supplied to the customer at each stage for approval. The project entailed numerous processes including upset forging, drop forging, hot bending, machining and an extensive testing regime.

Starting with fully certified and ultrasonically tested AISI 4140 round material, Brooks upset forged both bar ends using one of 16 forging cells on-site. These pre-formed ends were then drop forged by WHT using their 5T Banning power hammer. This stage of the process was critical as both ends had to be formed perfectly parallel. Specially designed jigs and fixtures were used to assist in meeting this requirement.

The components were hot bent to a 51° angle using specially designed tooling, followed by heat treatment to specific parameters in a fully calibrated furnace. Extensive testing was carried out including tensile and charpy with a 15.6T proof load test and magnetic particle inspection witnessed by Lloyds.

All tooling for the project was designed and manufactured in-house. Each bail bar was installed in a test jig that was specifically designed to mirror the final application. Packed suitably in custom built wooden cases and exported via air freight.

The Brooks Engineering Group can offer a wide range of manufacturing processes under one roof, enabling us to offer an unrivaled service and supply numerous industries with bespoke components that are not available elsewhere in the industry.