Forged Components For The Union Chain Suspension Bridge Refurbishment Project

28 September 2023

Brooks Forgings were approached to take part in the Union Chain Suspension Bridge restoration project, focusing on the manufacture of replacement chain rod ends and various supporting walkway components.

The Union Chain Bridge located in Northumberland spans the River Tweed connecting the Scottish and English borders. Designed by Sir Samuel Brown, the bridge opened in 1820 and was the world’s longest wrought iron construction suspension bridge spanning 137 meters and the first vehicular bridge of its type in the United Kingdom. The Union Chain Bridge is said to be the main influencer in bridge innovation and design which is reflected in the later-constructed Clifton and Menai suspension bridges.

In 2020, essential works were required to preserve the 200-year-old bridge as many of the original critical components had started to deteriorate and show signs of fatigue. The Spencer Group was appointed the project by Northumberland County Council to dismantle, replace, refurbish (where possible), and fully rebuild the bridge to mark its bicentenary.

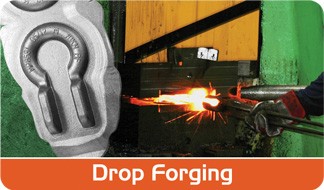

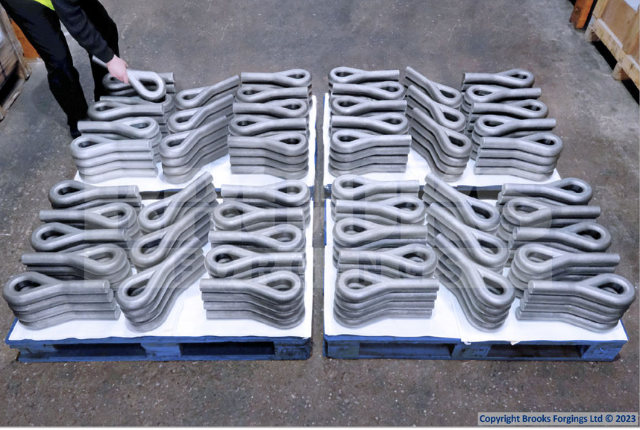

A total of 550 replacement chain rod ends were drop forged, machined, and supplied by Brooks Forgings enabling the replacement of 275 chain rods from the original 444 used in the construction. The chain rods are joined together to span the length of the bridge on both sides and are the key structural element in its design.

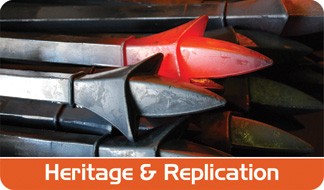

Along each side of the bridge are walkways that are constructed using decorative wrought iron handrail components. Brooks was able to produce a one-piece forged design remaining faithful to the original method of production.

The Brooks Engineering Group can assist with the production of critical forged components in support of historical bridge preservation or the construction of new modern engineering projects. Please get in touch with our team of experts who will be happy to assist with your specific requirements.