The Benefits of Single Source Procurement & Multistage Manufacturing From Brooks

28 September 2023

We have produced a video that demonstrates the benefits of using a single source supplier such as Brooks Forgings for all your component procurement and manufacturing requirements.

It is not uncommon for businesses to utilise multiple suppliers to produce single or multiple components for a specific project. For example, this may include a forger, a section bender, a machinist, a fabricator, and a finisher.

This can create many inefficiencies and problems such as:

· Sending out multiple RFQs.

· Waiting for and chasing multiple quotations.

· Placing and expediting multiple purchase orders.

· Make many phone calls to discuss progress, quality, or delivery concerns.

· Administration and project management costs are greatly increased.

· Extended lead times and unforeseen costs if one or multiple suppliers in the production chain fail.

· Multiple transportation costs, increasing carbon footprint.

A combination of some or all of these inefficiencies will cost you money, and time, and potentially repeat business if customers are let down with delivery deadlines.

If this scenario sounds familiar, Brooks Forgings can potentially offer you a solution.

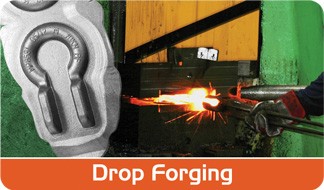

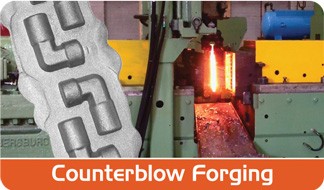

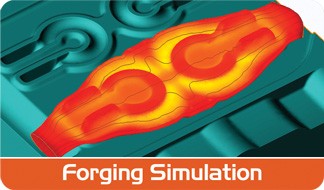

Brooks Forgings has an extensive range of in-house manufacturing processes that are supported by a dedicated and experienced sales, production, logistics, and quality team. By eliminating the requirement to outsource we can manage and process components more efficiently by having them at multiple stages in our factory simultaneously.

The benefits of working with Brooks Forgings:

· Send out one RFQ for single or multiple components.

· Receive one clear quotation detailing the price and lead time.

· Place and expedite one purchase order.

· Production processes are synced greatly reducing lead time and costs.

· Make one phone call to discuss progress, quality, or delivery concerns.

· Administration and project management costs are greatly reduced.

· One transportation cost, reducing carbon footprint.

With Brooks, you can be confident that you are working with an industry leader in forged, machined, and fabricated components. We have a proven track record in project management and streamlined production, achieved by our fully integrated, single-supplier approach.