Brooks Forgings Ltd

Brooks Forgings Ltd, established in 1960, is a leading UK manufacturer of Forged, Fabricated and Machined components.

We have a comprehensive range of manufacturing processes at our UK based facility and this aids buyers source their full requirements from one supplier.

These processes include:

- Robot Forging

- Upset Forging (16 cells)

- Drop Forging (10 cells)

- Horizontal Counterblow Forging

- Hand Forging

- Machining (14 cells)

- Fabrication & Assembly

- Robot Welding (5 cells)

- Flash Butt Welding

- Hot & Cold Bending

- Hot & Cold Pressing

- Thread Rolling

- Ring Rolling

- Swaging & Pointing

- Die Sinking

- Marking & Traceability

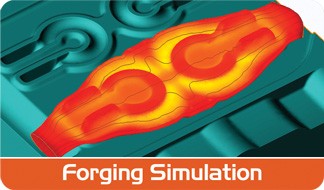

- Forging Simulation

- 3D Printing

- Reshoring

- 250 Tonnes of Raw Material

- 2500 Pallets of Customer Stock

Filter products and services

-

Hand Tools

We specialise in the manufacture and import of 'Non-Standard' Hand Tools, producing unique sizes and types to suit our clients exact specifications.Request a Quote Supplied by Brooks Forgings Ltd -

Hinge Pins

We manufacture and supply a large range of components for the skip and container refurbishment industry, including Skip Hinge Pins. Please find more information below.Request a Quote Supplied by Brooks Forgings Ltd -

Hinges

We supply a large range of Hinges. Hanging a gate? No problem, we offer hinges suitable for decorative and industrial applications.Request a Quote Supplied by Brooks Forgings Ltd -

Hollow Railing

Maximise your potential by utilising Brooks Tubular Hollow Rail, a new innovation in fencing manufacture. Railheads are forged directly on to tubes producing a unique ONE piece system. The advantages of having a ONE piece system are:- * Less welding (up to 75% reduction in welding per panel) * Less jigging (one piece tube, no lining up of heads etc) * Less cutting as tube is supplied to your pre-defined length * Less labour costs per panel Improved apperance:- * No unsightly welding, smoother finish * Heads are always in line with the bar below * Attractive designs * Varying heights are easily achieved above top railRequest a Quote Supplied by Brooks Forgings Ltd -

Hook to Hook - Turnbuckle System

As part of our standard tension system range we are able to offer a Galvanised Turnbuckle complete with Jaw each end. Formerly a U.S. Federal Specification.Request a Quote Supplied by Brooks Forgings Ltd -

Jaw to Jaw - Turnbuckle System 1

As part of our standard tension system range we are able to offer a Galvanised Turnbuckle complete with Jaw each end. Formerly a U.S. Federal Specification.Request a Quote Supplied by Brooks Forgings Ltd -

Jaw to Jaw - Turnbuckle System 1.1/2

As part of our standard tension system range we are able to offer a Galvanised Turnbuckle complete with Jaw each end. Formerly a U.S. Federal Specification.Request a Quote Supplied by Brooks Forgings Ltd -

Jaw to Jaw - Turnbuckle System 1.1/4

As part of our standard tension system range we are able to offer a Galvanised Turnbuckle complete with Jaw each end. Formerly a U.S. Federal Specification.Request a Quote Supplied by Brooks Forgings Ltd -

Jaw to Jaw - Turnbuckle System 1/2

As part of our standard tension system range we are able to offer a Galvanised Turnbuckle complete with Jaw each end. Formerly a U.S. Federal Specification.Request a Quote Supplied by Brooks Forgings Ltd -

Jaw to Jaw - Turnbuckle System 1.3/4

As part of our standard tension system range we are able to offer a Galvanised Turnbuckle complete with Jaw each end. Formerly a U.S. Federal Specification.Request a Quote Supplied by Brooks Forgings Ltd