Introducing the new ERV3

15 October 2020Our reliable and innovative ERack design has been a customer essential since its inception in 1995. In regular use by customers worldwide for the transportation, storage and protection of 19” rack-mount electronics. Our experienced product engineers have now developed many enhancements but retaining the same proven functionalities of the ERack design. Introducing the third generation of ERack (ERV3).

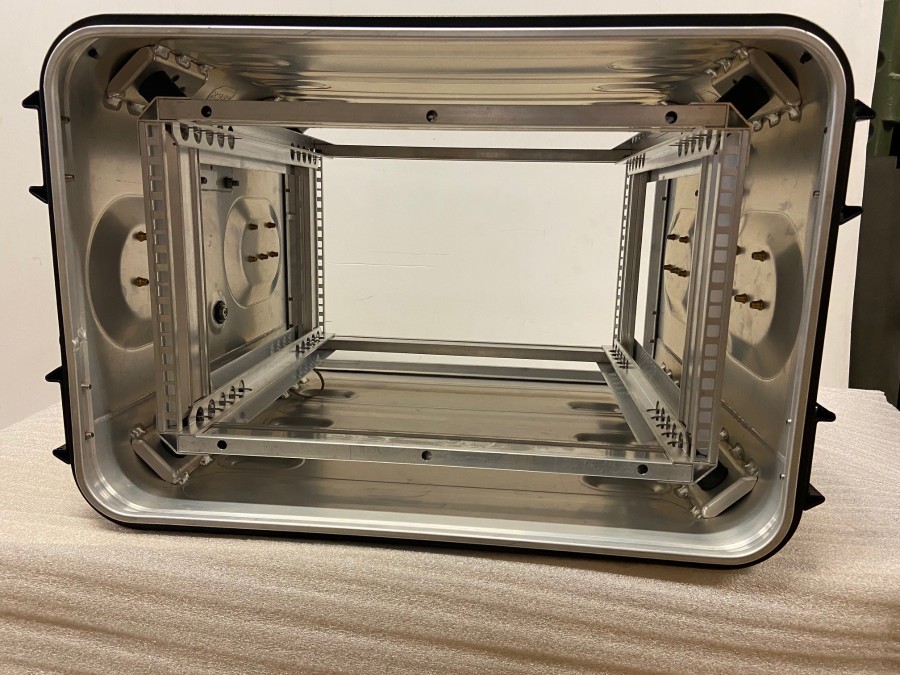

Lightweight rugged enclosure

You know the phrase 'if it's not broken, don't fix it'... well our ERV2 design was a hard act to follow, never mind improve on - but we know we have succeeded encapsulating all of the ERV3's predecessors’ best design features. With a lightweight rugged enclose as our starting point and matching the weight and strength of the ERV2, the new body design features large radiused edges and additional choices on venting and sunshade options.

The lids are press formed to give increased rigidity and stiffness, and precision formed dispensed with all welding processes; thereby eliminating potential leak paths. A choice of recessed rotary latches or surface mounted side latches remain available, together with options on connector panels. ERV3 lids can also accommodate customer branding, by either debossing or screen printing.

Hollow section extruded aluminium is CNC formed for the male and female profiles that are bonded to the body and lid to ensure a perfect ‘mate’. This provides the silicon gasket with a repeatable compression set forming the weatherproof protection for the interior of the EVR3 which are MIL-STD 810G and IP65 accredited.

New rotary latch design

The newly designed rotary latch is simple and comfortable to use – even with gloved hands. It provides a simple functional closure that resists shock and vibration and is calibrated to provide consistent compression for the weather gasket to seal perfectly.

Stacking Rubber Buffers and improved AV performance

A new feature on ERV3 is the option for large external self-stacking buffers. The 80 shore hardness TPEV rubber buffers provide additional protection in rough transit conditions through the non-slip positive stacking feature.

A new elastomeric AVM design has improved elastomeric excursion. This enhances the ERV3’s protection against shock and vibration.

Structural Bonding

ERV3 employs aerospace high-performance bonding technology, with two-part acrylic adhesives that offer excellent shear, peel, and impact performance. These toughened products provide improved adhesion to plastics and metals, featuring a fast cure rate, providing structural strength in minutes. Similar high-performance engineering has been used in other applications such as aeroplane manufacture and F1. (hyperlink case studies)

19” Shock-mounted Chassis

The ERV3 enclosures include the pioneering lightweight CV2 high tensile extruded 19" chassis. This gives the design infrastructure torsional rigidity and stiffness when the Rack is under severe loads. The Chassis is resistant to shock, drop, impact and vibration. CV2 chassis have been separately tested and accredited to MIL-STD-810G, and are iridited (surface coat conversion) when incorporated into EMC applications.

EMC Shielding

With the growing requirement for secure communications and protection from cyberattack, electromagnetic screening is often required to help prevent system hacks when in high-risk environments. Specialist conductive gaskets, use of wire mesh braid, embedded wire and Faraday cage features can be incorporated into the ERV3's design. This offers the customer various levels of EMC screening.

ERack products that incorporate EMC shielding are fitted with appropriate venting and pressure relief systems that perform to prerequisite emission Db levels.

It’s durability, functionality and lightweight monocoque construction makes the new ERack design the perfect ruggedised 19" rack enclosure for defence and commercial applications.