Which types of cases are best for transporting medical equipment?

25 October 2022When transporting medical equipment, it’s incredibly important that it’s securely stored in a case that protects the contents from potential damage. Any type of impact, from shock, vibrations or careless handling can have serious implications on vital medical equipment, so it’s fundamental that the type of case is considered to keep equipment safe and undamaged. Medical groups rely on having resistant and reusable cases for transit so CP Cases has used their expertise to help choose the best cases for transportation of medical products.

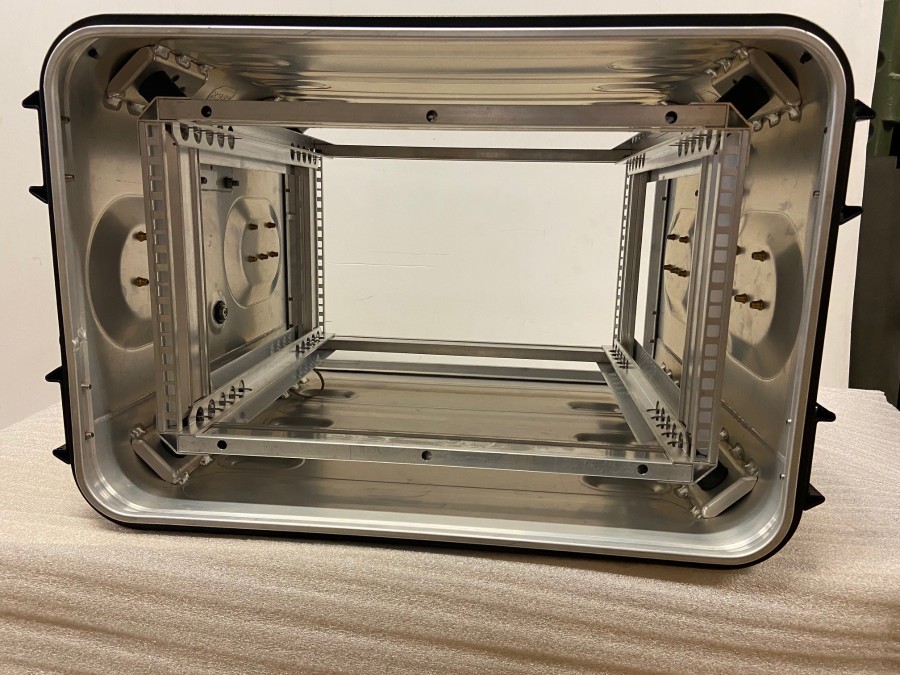

Aluminium cases

Aluminium cases are ideal for use in the medical industry as they are extremely strong and can protect contents under severe impact. These cases are manufactured in 2mm rigidised aluminium and are designed with indented corners and rounded edges for reinforced strength and safer handling. Aluminium cases can also be fitted with a specialised foam interior to add cushioning for more delicate contents.

CP Cases offers aluminium cases in two designs: AluCurve and AluWeld. There are differences between AluCurve and AluWeld, so it’s important to consider the type of equipment that will be stored before choosing which design to use. Highly valuable and breakable contents may be more secure in Alucurve cases as they have an incredibly high resistance to drop damage, whereas equipment that will be transported outside may be better suited for Aluweld, which is incredibly weather resistant.

Custom rotomoulded cases

Custom rotomoulded cases are another great option for the transportation of medical products and are designed specifically for customers’ needs. Cases are available in made-to-order sizes, so will be the exact dimensions needed for fitting the desired contents. Similar to aluminium cases, rotomoulded cases offer a great strength-to-weight ratio and can be fitted with foam inserts for additional protection. Rotomoulded cases are manufactured using polyethylene, which has high resistance to temperature changes and solvents. It’s also effortless to clean using steam or pressure washing and has zero fungal growth, making it easier to maintain hygiene standards – perfect for medical use.

These cases are suitable for any portable medical equipment needs and are ideal for renal patients looking for easier ways to transport vital medical equipment in a safe and convenient way. They also have a discrete design, having a suitcase-like shell, which may make it more comfortable for individuals to use on a day-to-day basis. The cases are relatively cheap, especially for lower production runs, so offer a more cost-effective option on small orders.

Custom-built bags

Custom-built bags provide protection and lightness for easy medical transportation.

They can be fitted with specially-engineered non-absorbent foam to hold delicate medical products in place (such as surgical instruments or orthopaedic joints). They are better suited to smaller medical tools that are needed on the go and can be designed for optimum functionality, such as being able to choose the type of fastener or adding on handy clasps and clips. Another benefit of the custom-built bag is that they can be manufactured with hard-wearing waterproof materials so are ideal for portable use, whether indoors or outdoors.

What are the advantages of custom-made medical cases?

There are many advantages of having custom-made medical cases, which is likely why 85% of CP Cases output to the medical industry are custom-made orders.

Having customised medical cases allows for a design that will suit a client's exact requirements. Having a tailor-made medical transportation solution means the level of protection works in harmony with the functionality and usability of the case. For example, customising a durable case to include wheels and extendable handles for smoother transportation. It also means increased protection for the medical equipment as interior protective cushioning can be fitted to hold the exact shape and size of the contents, reducing any internal movement during transportation. Additional drawers and trays can be added too to keep smaller, delicate pieces of equipment organised and secure.

Having a case to suit your exact requirements will make transporting medical equipment easier and more secure than opting for a standardised case design.

If you are interested in finding out more about medical cases, get in touch with CP Cases today.