David Bowler and Sons Ltd

David Bowler & Sons Ltd are a family business established by the late David Bowler in the 1940's which became limited in in 1965.

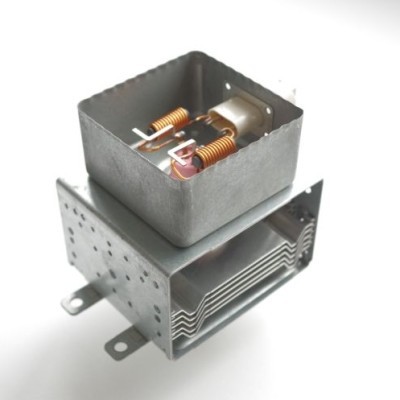

The company prides itself in specialising in the manufacture of medium to high volume Metal Pressings/Stampings to a wide and varied range of Industrial Clients both within the UK and Overseas.

Range of Press including:-

- Mechanical Presses from 10T - 400T, including Aida Transfer Presses, Progression and Single Operation Presses.

- Hydraulic Presses from 12T -320 T, including 2 off x 4 Transfer Press lines with Aida Line-Pacers.

Assembly and Packaging Facilities.

Progression Tooling Presswork

As well as single operation presswork, progression tooling presswork is another production process we regularly employ.

Progression tooling presswork utilises one tool for a number of differing operations, each one following the other. With this process, materials are used in coil form.

***Call us on 023 8084 9272 or 023 8084 3109 - Please remember too mention you found us on the Applegate Marketplace.

Transfer Tooling Presswork

A third presswork process we use is transfer tooling presswork. Transfer tooling presswork utilises a number of individual tools where individual components are automatically transferred from one stage to another until the production of the final component.

With transfer tooling presswork, tools are either mounted into one large bed tooling area or mounted into numerous presses joined together with automatic feeding equipment.

***Call us on 023 8084 9272 or 023 8084 3109 - Please remember too mention you found us on the Applegate Marketplace.

Single Operation Presswork

As expert manufacturers of high volume, intricate and challenging presswork, we utilise various manufacturing processes to ensure the most accurate and high quality end result. One of these processes is single operation presswork.

Single operation presswork involves using individual tools in separate presses or stamps with operations often undertaken by hand. Occasionally, pick and place robots are used.

***Call us on 023 8084 9272 or 023 8084 3109 - Please remember too mention you found us on the Applegate Marketplace.

Defence

We are long established manufacturers of custom metal pressings and stamped components on behalf of defence & MOD markets. Over the years we have gained invaluable knowledge in pressing parts in a wide range of materials, complex geometries, finishes & colours which are appropriate for the challenging terrains they are used in.

***Call us on 023 8084 9272 or 023 8084 3109 - Please remember too mention you found us on the Applegate Marketplace.

Military

To endure harsh elements & physical strain defence metal pressings undertake, DBS manufacture high integrity presswork to exacting customer specification. We have worked on many projects over the years, from camouflaged pressed panels used for armoured vehicles, to smaller components that can handle the sudden rigor put upon them. Our comprehensive facilities, systems & skilled engineers ensure that the MOD and defence sector receive structurally sound quality metal presswork on time, every time!

***Call us on 023 8084 9272 or 023 8084 3109 - Please remember too mention you found us on the Applegate Marketplace.

Construction

We work closely with engineers and professional buyers requiring metal stampings & presswork within the construction and building industry. Whether its electrical housing pressed parts, enclosures or heating & ventilation presswork, our team have the capabilities and experience to deliver quality metal stampings & components on time and to exacting requirements.

***Call us on 023 8084 9272 or 023 8084 3109 - Please remember too mention you found us on the Applegate Marketplace.

Metal Pressings

David Bowler and Sons Ltd offer a wide range of metal pressing services to meet the varying needs of our diverse customer base. We provide highly productive hydraulic and mechanical power presses from 400 tons to quick metal forming capabilities for high speed metal pressed parts & pressings.

***Call us on 023 8084 9272 or 023 8084 3109 - Please remember too mention you found us on the Applegate Marketplace.

Deep Drawn Pressing

We have many years experience in pressing deep drawn components in complex shapes, sizes, strengths, and finishes. Our expertise in this area is back-up by our comprehensive in-house tool manufacturing capabilities in conjunction, with our approved specialist toolmakers to ensure both progression and transfer tooling is produced in good time & to precise specification. This ensures our clients receive quicker turn around times and less room for error using third parties.

***Call us on 023 8084 9272 or 023 8084 3109 - Please remember too mention you found us on the Applegate Marketplace.

Feed Equipment

Our feed equipment complements our pressing operations, with various custom coil handling & transfer systems in place to aid lean manufacturing production.

- Aida THL and NC3H Line Pacer Transfer Systems

- Atkin and BHP Cradle Decoilers / Levelers with Flex arm controllers, Various sizes and Capacities

- Atkin Twin Mandrel Decoilers / Levelers with Sprint motor control and Loop controls

- Shung -Da 2.5 ton Single Mandrel Decoiler / Leveler

- 800mm Coil Handling Line consisting of : Atkin RF127-800 Roll feed, Atkin 800mm Leveler Head and Atkin Single Mandrel Decoiler with snubber.

***Call us on 023 8084 9272 or 023 8084 3109 - Please remember too mention you found us on the Applegate Marketplace.

Sheet Metal Division

Raskin RT085 Turret Punch with RADAN RadPunch DNC with a capacity of 2000 x 1000 mm sheets up to 6 mm thick

***Call us on 023 8084 9272 or 023 8084 3109 - Please remember too mention you found us on the Applegate Marketplace.

Sundry Equipment

- HARTRIDGE Setabush Nut Insertion Hyraulic Presses, with automatic Feed Bowls

- Hirst 90 KVa Projection welders

- Meritus 15 KVa spot welder

- Meritus 6 KVa Spot Welder

***Call us on 023 8084 9272 or 023 8084 3109 - Please remember too mention you found us on the Applegate Marketplace.

CADCam System

- AutoCAD Computer Aided Design and Draughting system

- This system can be run independently or through a direct link to the Turret Punch via the RADAN RadPuch software

***Call us on 023 8084 9272 or 023 8084 3109 - Please remember too mention you found us on the Applegate Marketplace.

Finishing Equipment

- Fully Automatic Acton Vibrota De burring Line with Dryer

- Vanco Barrel Finishing / De burring Machine

**Call us on 023 8084 9272 or 023 8084 3109 - Please remember too mention you found us on the Applegate Marketplace.

Shearing

- Haco PS 306 Guillotine with RoboSoft SC90 CNC controlling

- fully adjustable backguage, rake angle and blade gap

- Capacity : 3000mm cut length and up to 6mm Mild steel

- Haco TS 3006 Guillotine Manual Adjusted Back Gauge, rake angle and blade gap

- Capacity : 3000mm cut length and up to 6mm Mild steel

***Call us on 023 8084 9272 or 023 8084 3109 - Please remember too mention you found us on the Applegate Marketplace.