Tips and Decision-Making Tools For Choosing The Best Aisle Containment Solution For Your Data Centre

29 June 2022Tips and decision-making tools for choosing the best aisle containment solution for your data centre

For everyone, who intends to or is intending to realise energy savings in the data centre, it can be worth taking a closer look at the airflow path of conditioned air from the source of production to the hardware in the cabinets that require cooling. In the worst cases, up to 60 percent of the cold conditioned air can be lost through bypass airflow. This can be through openings in the raised floor, free rack U space that is not sealed, through aisles that are not contained and under the raised floor because of missing or inefficent guidance of the airflow. All these factors have dramatic impact on costs: While newer CRAC unit installations in the best case only contribute to around 10 percent to the total energy costs, the proportion of older installations often exceeds the 60 percent mark. This is particulary true for legacy data centres that have been operating for a number of years, but it is also true for newer data centre environments. There are great opportunities for optimising the efficiency of cooling and airflow guidance to save energy costs and to increase the sustainability of the data centre.

What are the saving potentials of optimised cooled air guidance and aisle containment?

Due to the fact that many data centre designs rely on complete room air-conditioning instead of cooling contained cold aisles, it is estimated that between 20 and 30 percent of the cooled air gets lost and wasted through bypass airflow. This is compounded by the fact that still in some data centre environments the server cabinets are not arranged back to back as separate hot and cold aisles. Therefore, at a basic level nothing is done to prevent the mixing of cold and hot air. Of course it is not disputed that this basic approach does not lead to a perfect separation of hot and cooled air, since the hot air rises up the rear of the cabinet, it flows over the top or around the side of the cabinet and re-circulates to the front of the rack. In addition, the hot air can also re-circulate into the cold aisle through non-sealed openings between servers or vertical profiles within the cabinet. Therefore, it is essential to hermetically seal the cold from the hot aisle with a containment solution. With constant cooling input, measurements show the temperature differential between the hot and cold aisle can be up to 10 to 15 degrees Celsius. This allows for the room temperature to be raised – and for every degree Celsius set points are raised an estimated 2-3 percent energy savings can be made.

There is no such a thing as “the“ aisle containment solution

There are a wide range of aisle containment systems from different vendors in the market. Frequently, structural solutions are offered that consist of rigid side profiles, sliding doors and ceiling panels. These components are usually mounted directly around the cabinets that are installed side by side forming the cold and hot aisle. As an alternative, flexible curtain containment strips can be used, which are assembled to overlap and are mounted via special supports directly onto the aluminium profiles, which are hung from walls, ceilings or directly onto the rack. Correctly installed, the efficiency rate of this kind of curtain solution is nearly the same level as one of a solid containment system.

If the containment system is to be installed into an existing data centre, then some aspects in terms of preliminary planning, material preparation, project duration and costs will have to be taken into account. When a soft or solid construction is planned, then ideally all the measurements will have to be taken very accurately onsite in the data centre so that all profiles, panels or curtain strips can be exactly tailored at the manufacturer’s production facility. If this preliminary planning has not been carried out very accurately or in the case that alterations might become necessary on the customer’s premises, then some re-working, fine cutting and redesigning will have to be done to materials such as glass, metal, plastic or brackets. This can lead to greater build time and costs, if the materials are not modular or prefabricated in a way that adjustments can be performed quickly and smoothly.

In choosing the most suitable containment variant, the nature and structure of the rack environment plays a big role, If it is a homogeneous one, with cabinets from one vendor with identical dimensions, then a common solid containment system can be created at a reasonable cost, using standard profiles and panels. Whereas in heterogeneous (commonly known as „Manhattan Skyline“) environments with different cabinets, heights and depths that have grown organically without the benefit of a clean sheet design, the use of a modular containment solution with solid or soft or a combination of both elements has proven to be effective in terms of flexibility, low installation time and costs.

Considering the integration of existing fire alarm infrastructure prevention systems

When making the decision as to what kind of containment solution should be installed, it is very important to take into account that the existing fire alarm and extinguishing systems need to be integrated. When containing the aisle with curtains this integration can be done usually by simply mounting the curtain under the ceiling of the data centre. In the case of a solid containment solution being chosen, then it should be assumed that the containment ceiling construction should automatically fall away in the event of a fire. The containment roof uses heat sensitive panels so if the temperature in the immediate vicinity climbs to 57 degree Celsius, then the feather-light panels will drop into the aisle, the roof of the containment system falls away meaning the aisle is open and the fire suppression system can automatically be deployed completely filling the area.

Special consideration when extending, dismantling and re-using

When adding cabinets with identical dimensions to the existing ones, then the installation element is straightforward as usually only the doors require relocation and additional standard roof or framework elements need to be mounted. A simpler and less time consuming kind of expansion can be realised with a modular containment system. As it is time consuming and difficult using standard solid structural solutions in terms of dismantling and reusability: Panels that are cut to size or screwed together are very limited in how they can be reused in other places in homogeneous environments and it is nearly impossible to reinstall these in heterogeneous rack surroundings. The situation is different with the modular alternative: The profiles for the ceiling, wall or frame to which solid panels or curtain strips are attached can be easily dismantled and reused in another location. Most of the elements of a modular system allow themselves to be reused in any rack arrangement, newly customised or supplemented by new elements at very low costs.

Solid and soft aisle containment combine together into a hybrid solution

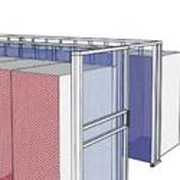

Due to the advantages and disadvantages of solid and soft containment described above, it is clear that a choice has to be made by data centre managers as to which system to use. But this does not neccessarily have to be the case, since the Intelligent CoolControl Containment solution from Daxten integrates both containment types and offers the use of this hybrid system for cold aisle and hot aisle containment.

This hybrid solution consists of aluminium profiles that can be connected to form a frame, which can be attached to walls, ceilings or racks. The frame offers a simple system to attach the soft containment curtains elements or to connect solid panels made of plastic, glass, steel or Perspex or a combination of all of these. Due to this concept and design, data centre professionals can profit from a wide range of choices and user advantages. As an initial guide to find a suitable solution, it might be worth taking a look at the following key questions:

1.) What would you like – containing the cold or hot aisle?

First of all it is recommended to check if a cold or hot aisle containment system would better be suited to the specific data centre environment. The more common method is to contain the cold aisle, however, it is also not unusual to contain the hot aisle with a hybrid system „to catch“ the hot exhaust air. The heat dissipation can be managed by in-row cooling systems that are integrated into the rack rows to cool down the hot air. In this instance, the cold aisles are supplied with conditioned air through the existing room cooling capacities. This method does not require a raised floor infrastructure that is typically required, when a cold aisle containment solution is implemented.

2.) How to get the maximum efficiency out of your investment?

Ideally before you start planning a containment solution, a thermal and energy usage analysis of the data centre environment should be carried out. That way, the potential benefits of the airflow and cooling optimisation measures as well as the energy savings can be determined. And of course it is important to be able to prove that the identified optimisation potential can be atained in practice. A hybrid containment solution offers a budget-friendly test run by simply starting with the containment of one rack row. The metrics received from this trial should be analysed and projected. On the basis of this trial, the user can decide, if a soft, solid or combination of both methods would fit best to their environment. In the same vain, the pay-back period and return on investment can be estimated quite accurately.

3.) Solid, soft or hybrid containment? The character of the room driving the design

Special attention will have to be paid on differing ceiling heights, ceiling joists, support columns and further structural restrictions in the data centre as well as number, dimensions, density and floor footprint of the cabinets. Another important role the infrastructure plays is for the prevention of fire. And last but not least, it should be considered, if racks will be added to single rows or if new cabinet rows are planned for future expansions. A rule of thumb could be: The more structurally rugged the environment and heterogeneous the rack infrastructure is, the more it is recommended to choose a modular containment design. The option to perform at any time a structural retrofitting or to setup a combined soft and solid containment solution, provides the maximum of flexibility and protects the investment in the long-term.

Essentials for exploiting the full potential of an aisle containment solution

A hybrid system does not only combine the advantages of common containment systems, it also integrates further modules and methods for the optimisation of airflow guidance and cooling air pressure, which help to realise the full potential of an aisle containment solution. Included in these optimisation best practices are simple blanking panels which are used to seal the free U space of racks in the cold aisle. With this inexpensive measure a weak point of cold aisle containment can be eliminated that is not on anyone’s radar: It prevents the recirculation of hot exhaust air of the IT hardware through the cabinet. The physical barrier keeps cold air at the front of the cabinets in the cold aisle separated from the hot air at the back in the hot aisle. This leads to higher cooling efficiency, prevents hot spots and resulting hardware failures or downtime caused by overheating.

A further key building block are perforated floor tiles, which manage the constant pressure of the cold air supply out of the raised floor into the front of the cabinet hardware in the cold aisle. To get rid of bypass airflow and thermal imbalances directly in the rack, special raised floor baffles with integrated cable openings and elastomer grommets are used. The baffles shoud have a high load-bearing capacity which can handle, for example, the weight of fully equipped server racks. The integrated grommet securely seal the cables to ensure that no cold air escapes in these places and to prevent dust and foreign particles from being blown into the inside of the rack from the raised floor which could result in operating malfunctions or shortened service life of the hardware. The grommets also prevent cold air from escaping from the rear of the rack. The lighter warm air emitted by the hardware would otherwise be vertically channelled to the top of the rack allowing it to flow back along the sides. This is quite an effective way of keep hotspots from forming and to maintain the efficency of the cabinet cooling.

Monitoring makes containment even better

To take and analyse measures such as temperature, relative humidity and differential pressure within a contained aisle, it is recommended to use a monitoring solution. Why is this important? Of course, to identify critcal temperature developments and to be alarmed at once, before it leads to downtime or damages to the hardware or power inefficiencies. The well balanced pressure of the conditioned air inside the contained cold aisle is important as well – not only to prevent high loads and associated costs of the cooling units, but also to avoid the fans of the servers in standby mode being set in motion because of too high air pressure as this could result in possible damages. In addition, it should be considered that the relative humidity plays an essential role too. If it is too high in the contained aisle, then the servers need to regulate the condensation, which goes along with incresed power consumption. If the specified values for humidity of servers are exceeded continuously, then there exists the risk of corrosion, hardware failures and downtime. In the case that the humidity becomes too low, this could lead to static charging of the active IT devices and short circuits.

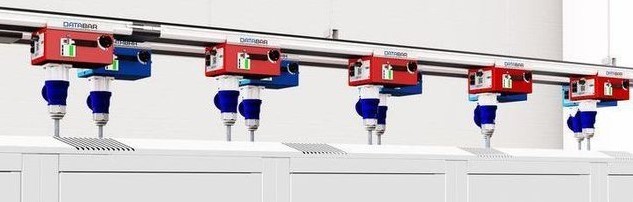

There are quite a lot of monitoring solutions in the market to control the mentioned parameters. Particulary smart a wire-free radio monitoring solution called Packet Power get’s this job done. The special feature is that the sensor modules communicate via a dedicated wireless mesh radio network (no WiFi), they are self-configuring, require no cabling work and are therefore very easy and quick to implement. All measurement data is transferred wirelessly to a gateway and accessible via a dedicated system management tool or any third-party DCIM or BMS application. If it comes to critical develompents in regards to temperature, differential pressure or humidity inside or outside the contained aisle, the IT personnel will receive alarm notifications. Since the system can easily be extended with wire-free power monitoring modules, power measurements on any distribution level within the rack or room can be taken and transferred wirelessly to the data centre management tool. With all environmental and power data at hand, the perfect basis for planning is given to equip each cabinets with the optimal number of active devices and to balance power as well as cooling loads efficently.

Enhancements, benefits and the icing on the cake

With the integration of the methods for the optimisation of the conditioned airflow into a hybrid aisle containment system and the additional monitoring solution it is possible to increase the effectiveness of such a containment application compared to other common solutions. In total and depending on size and layout of the data centre environment, the efficiency enhancement can exceed significantly the 30 per cent mark as mentioned in the beginning. Concrete cost savings result from the more efficient use of existing cooling capacities and are also reflected in the reduced loads of the CRAC units. Additional indirect economic advantages are associated with the following functional benefits: Constant humidity, well balanced pressure of the cooled air and low environmental temperature within the contained aisle extend the lifetime of the cabinet hardware and protect these against inefficient operating conditions, heat releated malfunctions and downtime.

Further a hybrid system convinces with its modular design and the option to contain the hot or cold aisle, with curtains, structural material or a combination of both. Low material costs, tailored prefabrication of profiles,panels and curtain strips as well as flexible and quick customisation possibilities at the data centre premises contribute to time and financial savings. If further taking into account the given extension, dismantling and reuse options, then tangible economical advantages are also offered for the medium and long-term. All in all, Daxten estimates that the average amortisation period of common containment solution which normally is between twelve and eigtheen months can be reduced by a couple of months when using a hybrid solution.

Hosting and colocation providers will appreciate that Daxten offers wire mesh and metal sheet panels for its containment system for additional security. Compartments can be installed both quickly and flexibly with the aluminium base profiles – of course with integrated containment at the customer's request.

To dive deeper into this subject and for more best practices to optimise your data centre infrastructure, please contact us on +44 (0)20 8991 6200 or via info.uk@daxten.com.